A kind of titanium-germanium composite catalyst for polyester synthesis and its application

A composite catalyst, titanium germanium technology, which is applied in the field of polyester synthesis, can solve the problems of not being used on a large scale, the yellow hue of polyester products, and the low stability of the catalyst, so as to achieve good industrial application prospects and prevent yellow hue , Improve the effect of stability and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Catalyst preparation:

[0039] 1) At room temperature, the titanium compound is added dropwise into an aqueous hydrochloric acid solution, and stirring is continued for 1-6 hours after the dropwise addition to obtain a titanium dioxide sol. Preferably, the titanium compound is titanium alkoxide, at least one of tetraethyl titanate, tetrapropyl titanate, tetraisopropyl titanate, tetrabutyl titanate, and tetraisooctyl titanate. The concentration of the hydrochloric acid aqueous solution is 0.05-1 mol / L, and the molar ratio of the titanium compound to the hydrochloric acid is 1-10:1.

[0040] 2) At room temperature, germanium tetrachloride was added dropwise to deionized water, and stirring was continued for 12-24 hours after the dropwise addition to obtain a germanium dioxide sol. Preferably, the molar ratio of germanium chloride to deionized water is 0.01˜0.5:1.

[0041] 3) At room temperature, mix the titanium dioxide sol and the germanium dioxide sol, add the mixed s...

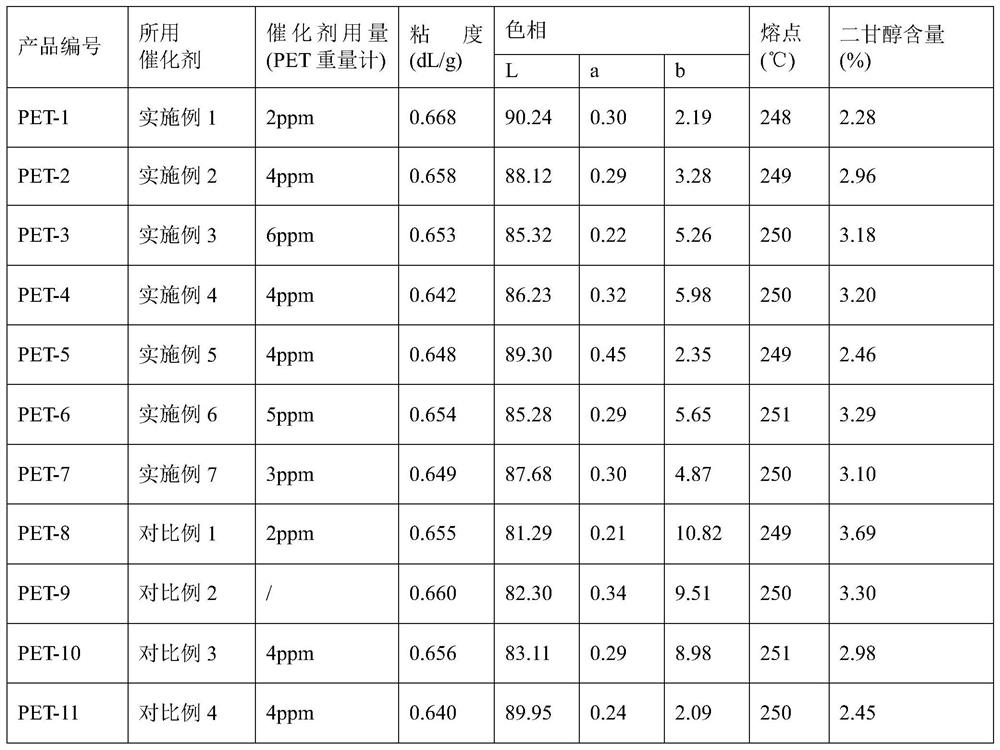

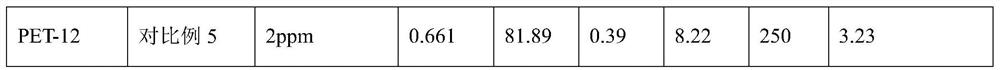

Embodiment 1

[0046] At room temperature, 4.5 mmol of tetrabutyl titanate was added dropwise to 20 mL of 0.1 mol / L hydrochloric acid solution, and stirring was continued for 3 h after the dropwise addition to obtain a titanium dioxide sol. Add 1.5 mmol of germanium tetrachloride dropwise to 2.5 mL of deionized water, and continue stirring for 15 h after the dropwise addition to obtain a germanium dioxide sol. Mix the titanium dioxide sol and the germanium dioxide sol, add the mixed sol dropwise into 150 mL ε-caprolactam aqueous solution with a concentration of 0.14 mol / L, and continue stirring for 1 h. The precipitate was obtained by centrifugation, washed with deionized water to remove chloride ions, and vacuum-dried at 100° C. to constant weight to obtain a titanium-germanium composite catalyst. Table 1 shows the performance results of polyester chip products prepared by using this catalyst.

Embodiment 2

[0048] At room temperature, 10 mmol of tetraisopropyl titanate was added dropwise to 20 mL of 0.2 mol / L hydrochloric acid solution, and stirring was continued for 4 h after the dropwise addition to obtain a titanium dioxide sol. Add 5 mmol of germanium tetrachloride dropwise to 8 mL of deionized water, and continue stirring for 20 h after the dropwise addition to obtain a germanium dioxide sol. Mix titanium dioxide and germanium dioxide sol, add the mixed sol dropwise to 300mL citric acid aqueous solution with a concentration of 0.1mol / L, and continue stirring for 2h. The precipitate was obtained by centrifugation, washed with deionized water to remove chloride ions, and vacuum-dried at 80° C. to constant weight to obtain a titanium-germanium composite catalyst. Table 1 shows the performance results of polyester chip products prepared by using this catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com