Steel belt corrugated pipe and preparation method thereof

A corrugated pipe and steel belt technology, applied in the field of pipelines, can solve the problems of poor performance of steel belt corrugated pipes, poor heat resistance and rigidity, etc., and achieve the effects of reducing viscosity, improving processing performance, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

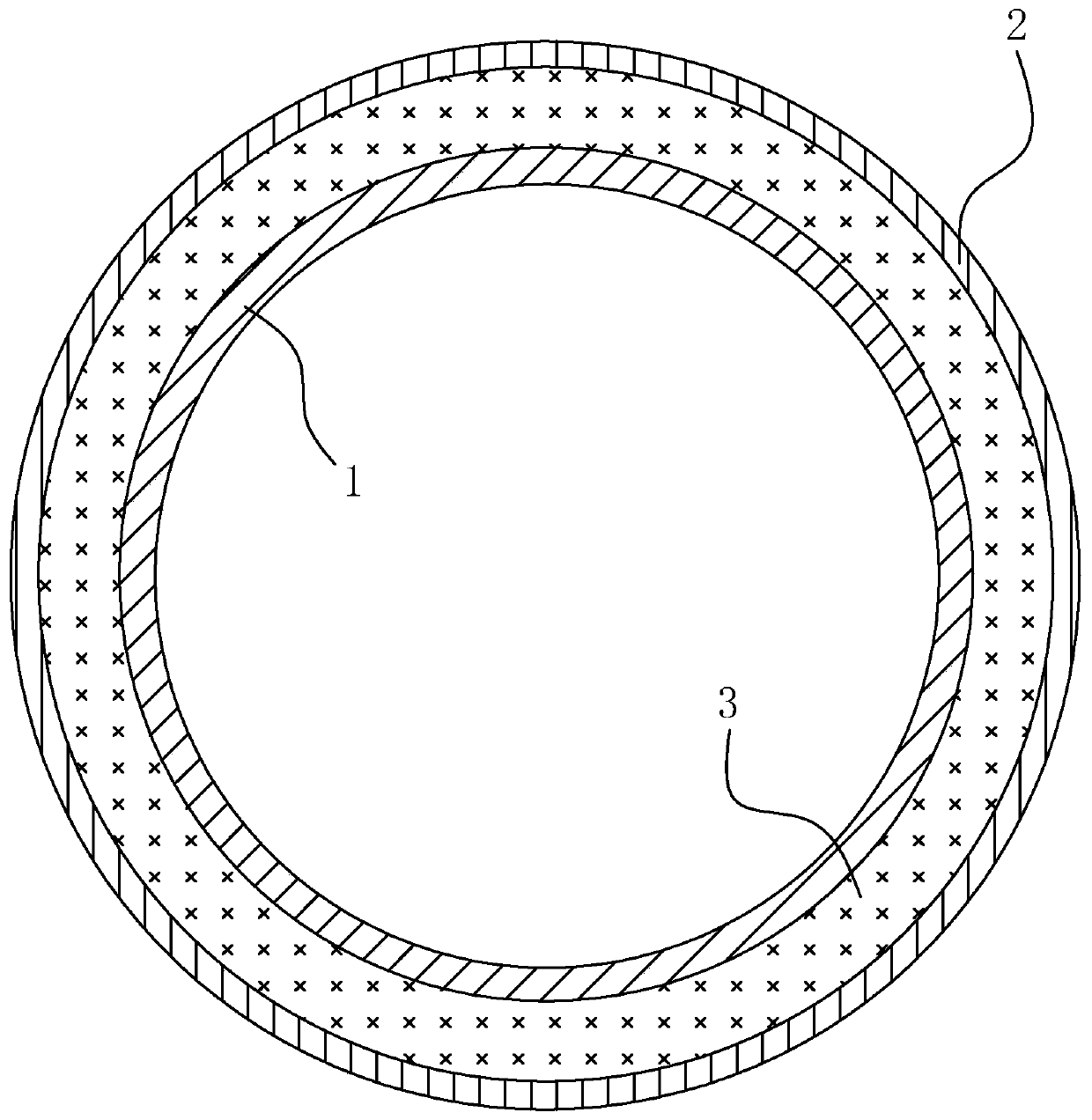

Image

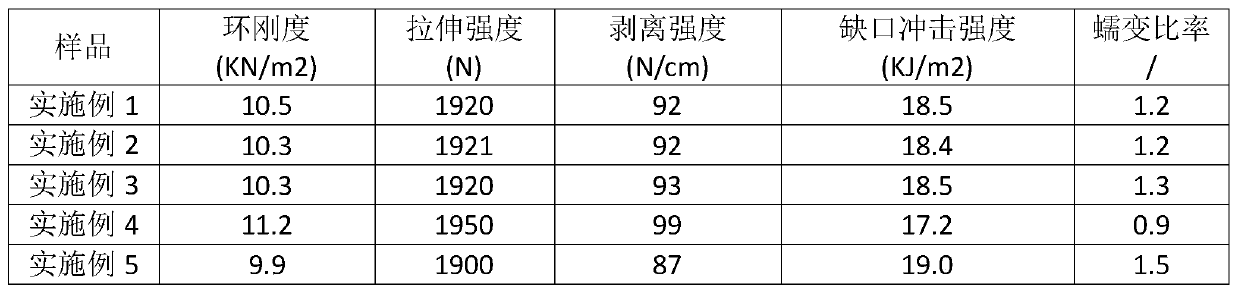

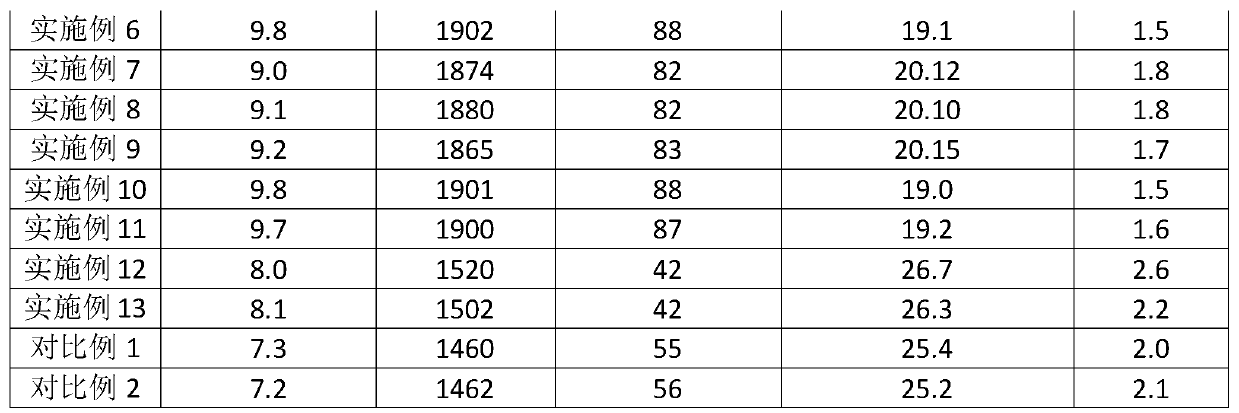

Examples

Embodiment 1

[0045] A method for preparing a steel strip bellows comprises the following steps:

[0046] Mix and stir 35.56kg polyvinyl chloride and 44.44kg polyethylene evenly to obtain a blend of polyvinyl chloride and polyethylene, then add 7kg chlorinated polyethylene and 0.8kg dicumyl peroxide, mix and stir evenly to obtain a mixture .

[0047] Put the mixture, 75g of clove essential oil, 25g of vitamin E, 0.8kg of dioctyl phthalate, 0.2kg of glycerin, 5kg of glass fiber and 0.5kg of hydrotalcite stabilizer into the mixer and stir evenly, then into the kneader , melted at 140°C for 15 minutes, and finally sent to a twin-screw extruder for extrusion to obtain a melt.

[0048] The galvanized steel strip is uncoiled, flattened, cleaned with water to remove dust and other impurities on the surface, dried, and the steel strip 3 is textured and coated with plastic, and then the adhesive resin is evenly coated on the galvanized steel strip surface.

[0049] The molten material is bonded a...

Embodiment 2

[0051] A method for preparing a steel strip bellows comprises the following steps:

[0052] Mix and stir 46.36kg of polyvinyl chloride and 38.64kg of polyethylene to obtain a blend of polyvinyl chloride and polyethylene, then add 9kg of chlorinated polyethylene and 1kg of dicumyl peroxide, mix and stir to obtain a mixture.

[0053] Put the mixture, 250g of clove essential oil, 50g of vitamin E, 1.678kg of dioctyl phthalate, 0.33kg of glycerin, 6kg of glass fiber and 1kg of hydrotalcite stabilizer into the mixer and stir evenly, then into the kneader, It was melted at 160°C for 20 minutes, and finally sent to a twin-screw extruder for extrusion to obtain a melt.

[0054] The galvanized steel strip is uncoiled, flattened, cleaned with water to remove dust and other impurities on the surface, dried, and the steel strip 3 is textured and coated with plastic, and then the adhesive resin is evenly coated on the galvanized steel strip surface.

[0055] The molten material is bonded...

Embodiment 3

[0057] A method for preparing a steel strip bellows comprises the following steps:

[0058] 46.5kg of polyvinyl chloride and 46.5kg of polyethylene were mixed and stirred evenly to obtain a blend of polyvinyl chloride and polyethylene, and then 11kg of chlorinated polyethylene and 1.3kg of dicumyl peroxide were added, mixed and stirred evenly to obtain a mixture .

[0059] The mixture, 400g clove essential oil, 100g vitamin E, 875g dioctyl phthalate, 125g glycerin, 8kg glass fiber and 1.7kg hydrotalcite stabilizer are sent into the mixer and stirred evenly, then sent into the kneader, It was melted at 180°C for 25 minutes, and finally sent to a twin-screw extruder for extrusion to obtain a melt.

[0060] The galvanized steel strip is uncoiled, flattened, cleaned with water to remove dust and other impurities on the surface, dried, and the steel strip 3 is textured and coated with plastic, and then the adhesive resin is evenly coated on the galvanized steel strip surface.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com