Composite membrane for mabr and preparation method thereof

A composite membrane and fiber membrane technology, applied in the field of MABR composite membrane, can solve the problems of gas flux decline, low oxygen flux, and hydrophobic performance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

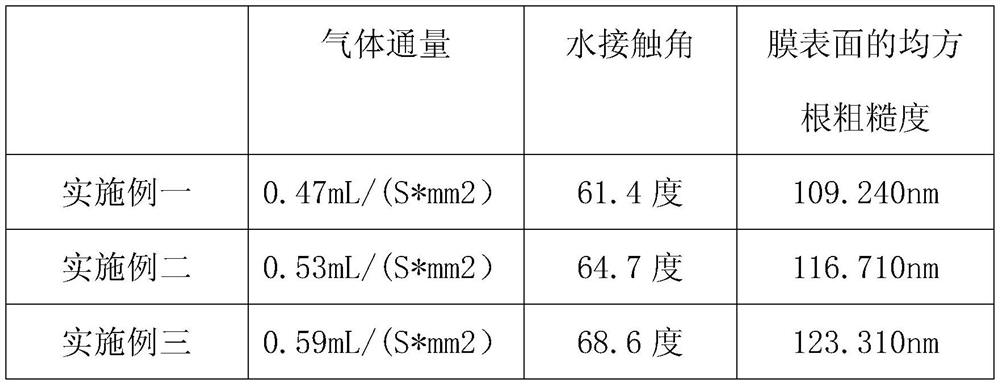

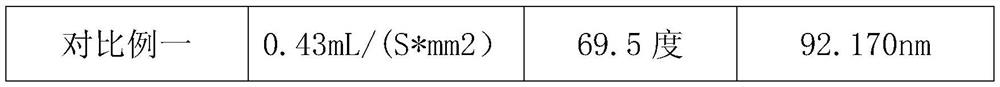

Embodiment 1

[0023] A composite membrane for MABR proposed by the present invention includes a composite hollow fiber membrane and multi-dimensional holes arranged on the composite hollow fiber membrane;

[0024] Its preparation method comprises the following steps:

[0025] S1: Put the polyvinylidene fluoride raw material and the 5% diluent of the polyvinylidene fluoride raw material in the reaction kettle, and melt at a high temperature at the same time, and control the heating temperature at 120°C;

[0026] S2: After complete melting, keep the temperature of the reactor at 60°C, stand in the reactor for defoaming, and start spinning after standing for 3 hours;

[0027] S3: Under the traction of the take-up wheel, the spun membrane filaments are extracted into the 70% mass ratio of polyvinylidene fluoride raw materials for extraction, the take-up speed is 400m / min, the cooling temperature is 30°C, and phase separation occurs during cooling The phenomenon forms pores, and the composite m...

Embodiment 2

[0031] A composite membrane for MABR proposed by the present invention includes a composite hollow fiber membrane and multi-dimensional holes arranged on the composite hollow fiber membrane;

[0032] Its preparation method comprises the following steps:

[0033] S1: Put the polyvinylidene fluoride raw material and the 5% diluent of the polyvinylidene fluoride raw material in the reaction kettle, and melt at a high temperature at the same time, and control the heating temperature at 130°C;

[0034] S2: After complete melting, keep the temperature of the reactor at 65°C, stand in the reactor for defoaming, and start spinning after standing for 3.5 hours;

[0035] S3: Under the traction of the take-up wheel, the spun film filaments are extracted into the 70% mass ratio of polyvinylidene fluoride raw material extraction solution, the take-up speed is 450m / min, the cooling temperature is 35°C, and phase separation occurs after cooling The phenomenon forms pores, and the composite ...

Embodiment 3

[0039] A composite membrane for MABR proposed by the present invention includes a composite hollow fiber membrane and multi-dimensional holes arranged on the composite hollow fiber membrane;

[0040] Its preparation method comprises the following steps:

[0041] S1: Put the polyvinylidene fluoride raw material and the 5% diluent of the polyvinylidene fluoride raw material in the reaction kettle, and melt at a high temperature at the same time, and control the heating temperature at 150°C;

[0042] S2: After complete melting, keep the temperature of the reactor at 70°C, stand in the reactor for defoaming, and start spinning after standing for 4 hours;

[0043] S3: Under the traction of the take-up wheel, the spun film filaments are extracted into the 70% mass ratio of polyvinylidene fluoride raw materials for extraction, the take-up speed is 500m / min, the cooling temperature is 45°C, and phase separation occurs during cooling The phenomenon forms pores, and the composite membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com