Preparation method of alginate metal cross-linked chitosan adsorption material and application thereof

A technology of metal crosslinking and composite adsorption materials, which is applied in the field of preparation of alginate metal crosslinking chitosan composite adsorption materials. Utilization, easy separation, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

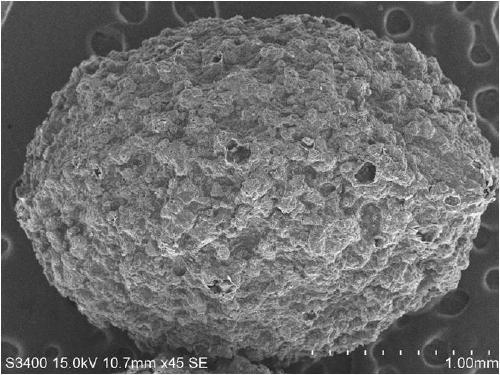

[0019] Weigh 2 g of chitosan powder, dissolve it in 100 mL of 1% dilute acetic acid solution under stirring with a magnetic stirrer, add 3.22 g of ZrOCl 2 ·8H 2 O, stirred at room temperature for 2-3 h to form a homogeneous mixed solution; added NaOH solution to adjust the pH>6; Add NaOH solution to adjust the pH>11; after sealing, cross-link in a refrigerator at 4°C for 12 h at low temperature; remove the supernatant of the suspension and take out the precipitate, dry it with an infrared dryer and wash it to neutral; dry and grind to obtain Zirconium-chitosan powder; weigh 6 g of the above powder and add it to 100 mL of 20 g / L sodium alginate solution, stir for 1 h to disperse it evenly; drop the above solution into 2% CaCl by constant flow pump 2 After solidification in the solution, the alginate metal cross-linked chitosan composite material can be obtained by freeze-drying. The appearance is brownish-yellow spherical particles, and the mass is about 3 mg / granule.

Embodiment 2

[0021] Weigh 100 mg of adsorption material and add it to sodium arsenate and sodium arsenite solutions with initial concentrations of 1, 5, 10, 15, 20, 30, 40, and 50 mg / L respectively, and adjust the pH value to about 2 at room temperature. Shake or stir for 48 hours. After the adsorption is completed, the solution and the adsorbent are separated, and the change of the concentration of arsenic in the solution before and after adsorption is measured by plasma emission spectroscopy, and the adsorption capacity of the adsorbent for arsenic is calculated.

[0022] Depend on image 3 It can be seen that the prepared alginate metal cross-linked chitosan composite adsorption material is spherical or ellipsoidal, and its particle size is about 2.0-2.8 mm.

[0023] Depend on Figure 4 It can be seen that the prepared alginate metal cross-linked chitosan composite adsorption material has a good adsorption effect on inorganic arsenic, and its maximum adsorption capacity for arsenic (Ⅲ)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com