Deep treatment process for wastewater at tail end of livestock breeding pollution

A technology for livestock and poultry breeding and wastewater, applied in the field of water treatment, can solve problems affecting the production and life of surrounding residents, achieve the effects of saving project investment, improving oxidation capacity, and reducing the toxicity of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

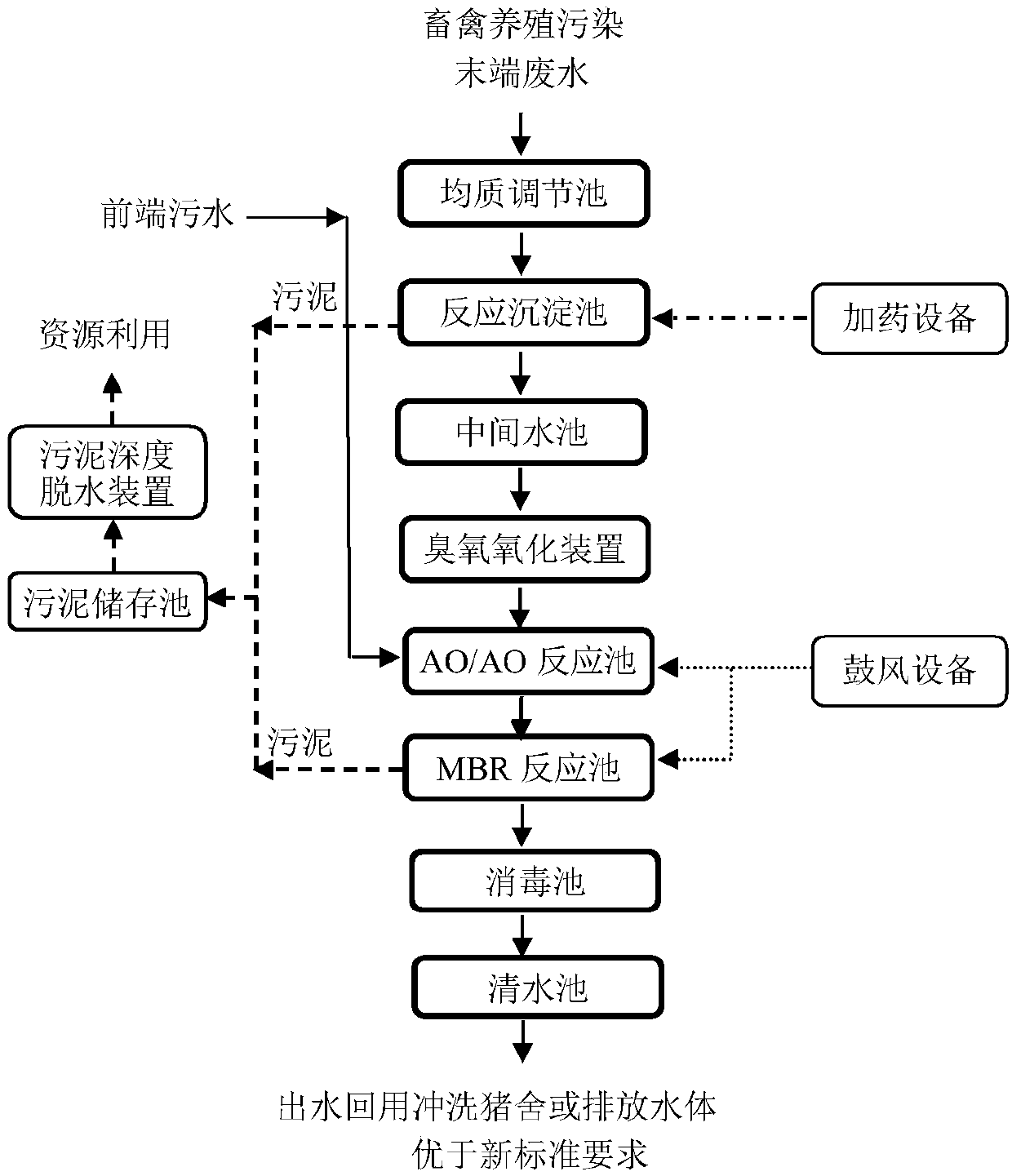

[0043] The advanced treatment process of livestock and poultry breeding polluted terminal wastewater in this embodiment is as follows:

[0044] The water quality of the polluted terminal wastewater from livestock and poultry farming to be treated is: COD Cr 400 mg / L, BOD 5 150 mg / L, SS 200 mg / L, ammonia nitrogen 80 mg / L, total phosphorus 8mg / L, total nitrogen 150 mg / L, the wastewater first enters the homogeneous adjustment tank, and the homogeneous and even volume of the wastewater is adjusted by the stirring device ; Then the effluent enters the reaction sedimentation tank, and 80mg / L PAFC is added for reaction and preliminary treatment of solid-liquid separation to remove suspended solids and part of the chroma in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com