Preparation method for environment-friendly tailor's chalk capable of fading color

An environment-friendly, step-by-step technology, used in dyeing, textiles and papermaking, pencil leads, etc., can solve problems such as difficulty in removing powder traces, appearance defects, etc., and achieve the effects of preventing aggregation, improving brittleness, and improving the smoothness of scribing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

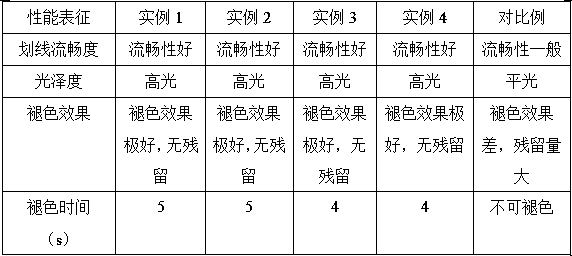

Examples

example 1

[0025] Wash the egg shell with deionized water and dry it naturally, grind it and pass through a 60-mesh sieve to obtain egg shell powder, mix the egg shell powder, deionized water and 10% nitric acid solution by mass fraction, and carry out stirring treatment, that is Obtain a mixed solution, filter to obtain a filtrate, adjust the pH value of the filtrate to obtain a mixed solution A; mix stearic acid and deionized water, and carry out constant temperature stirring to obtain a mixed solution B, which is mixed in a mixed solution with a mass ratio of 1:1. Add mixed solution A to B, and continue to stir for 10 minutes to obtain mixed solution C. Add 1 mol / L sodium hydroxide solution to mixed solution C, stir at a constant temperature of 50°C for 30 minutes, filter to obtain filter residue, and wash the filter residue. Drying treatment, cooling to room temperature, to obtain calcium stearate; take benzoic acid, gypsum powder, egg shell powder, calcium stearate, polyethylene wax,...

example 2

[0027] Wash the egg shells with deionized water and dry them naturally, grind them and pass through a 67-mesh sieve to obtain egg shell powder, mix the egg shell powder, deionized water and 10% nitric acid solution by mass fraction, and carry out stirring treatment, that is Obtain a mixed solution, filter to obtain a filtrate, adjust the pH value of the filtrate to obtain a mixed solution A; mix stearic acid and deionized water, and carry out constant temperature stirring to obtain a mixed solution B, which is mixed in a mixed solution with a mass ratio of 1:1. Add mixed solution A to B, and continue to stir for 13 minutes to obtain mixed solution C. Add 1 mol / L sodium hydroxide solution to mixed solution C, stir at a constant temperature of 53°C for 33 minutes, filter to obtain filter residue, and wash the filter residue. Drying treatment, cooling to room temperature, to obtain calcium stearate; take benzoic acid, gypsum powder, egg shell powder, calcium stearate, polyethylene...

example 3

[0029] Wash the egg shell with deionized water and dry it naturally, grind it and pass it through a 74 mesh sieve to obtain egg shell powder, mix the egg shell powder, deionized water and 10% nitric acid solution by mass fraction, and carry out stirring treatment, that is Obtain a mixed solution, filter to obtain a filtrate, adjust the pH value of the filtrate to obtain a mixed solution A; mix stearic acid and deionized water, and carry out constant temperature stirring to obtain a mixed solution B, which is mixed in a mixed solution with a mass ratio of 1:1. Add mixed solution A to B, and continue to stir for 16 minutes to obtain mixed solution C. Add 1 mol / L sodium hydroxide solution to mixed solution C, stir at a constant temperature of 56°C for 36 minutes, filter to obtain filter residue, and wash the filter residue. Drying treatment, cooling to room temperature, to obtain calcium stearate; take benzoic acid, gypsum powder, egg shell powder, calcium stearate, polyethylene w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com