Electrospun yarn with hydrophobic graphene composite macromolecular fiber and preparation method of electrospun yarn

A graphene composite, polymer fiber technology, applied in electrospinning, fiber processing, rayon manufacturing and other directions, can solve the problems of fiber breakage, non-filamentation, large preparation, etc., and achieves short reaction time, high degree of industrialization, Overcoming the effect of spinning discontinuities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for electrospinning of hydrophobic graphene modified polymer fibers, comprising the steps of:

[0032] (1) Graphene, polymethyl methacrylate and solvent dimethyl formamide are mixed and heated to 70°C for 10 hours with heating and stirring. In terms of mass fraction, 0.1% of graphene, 20% of polymethyl methacrylate, and the balance is solvent dimethylformamide;

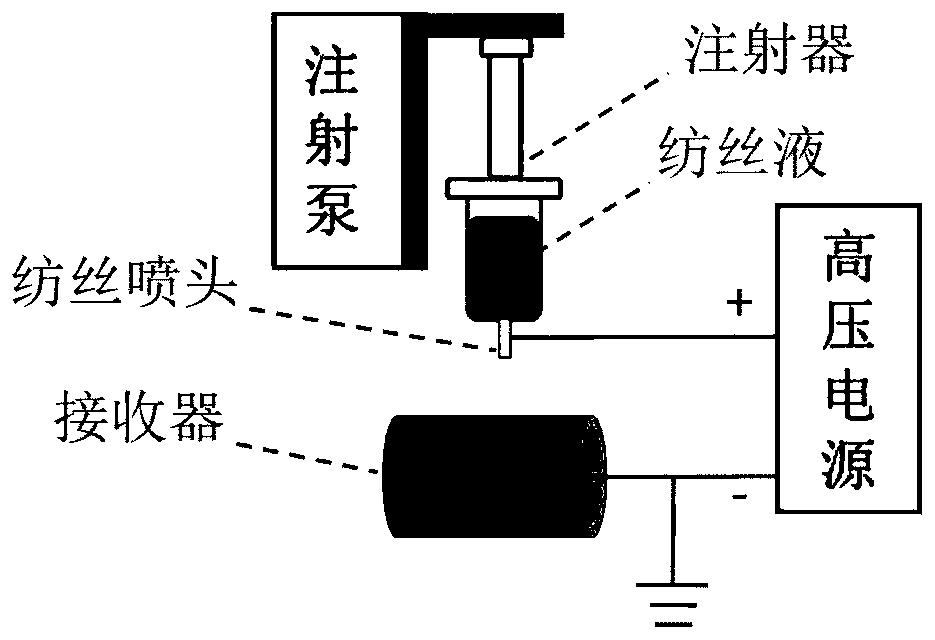

[0033] (2) Then the spinning solution is ultrasonicated in a water bath at room temperature for 4 hours; the ultrasonic spinning solution is put into a syringe, see figure 1 , set up the receiver, set up the electrospinning device, the distance between the nozzle and the receiver is 10-20cm;

[0034] (3) Electrospinning is carried out under the condition of 12kv voltage, spinning solution flow rate 2.0-4.0mL / h, and then obtains the electrospinning of hydrophobic graphene modified polymer fiber (see figure 2 , 3 ).

Embodiment 2

[0036] A preparation method for electrospinning of hydrophobic graphene modified polymer fibers, comprising the steps of:

[0037] (1) Graphene, polymethyl methacrylate and solvent dimethyl formamide are mixed and heated to 70°C for 10 hours with stirring, in terms of mass fraction, 1.5% of graphene, 20% of polymethyl methacrylate, and the balance is solvent dimethylformamide;

[0038] (2) The spinning solution is then ultrasonically placed in a water bath for 4 hours; the ultrasonically placed spinning solution is put into a syringe, the receiver is set, and the electrospinning device is set up. The distance between the nozzle and the receiving receiver is 10-20 cm;

[0039] (3) Electrospinning is carried out under the conditions of 12kv voltage and spinning solution flow rate of 2.0-4.0mL / h (see image 3 ).

Embodiment 3

[0041] A preparation method for electrospinning of hydrophobic graphene modified polymer fibers, comprising the steps of:

[0042] (1) Graphene, polymethyl methacrylate and solvent dimethyl formamide are mixed and heated to 70°C for 10 hours with heating and stirring. In terms of mass fraction, 3% of graphene, 20% of polymethyl methacrylate, and the balance is solvent dimethylformamide;

[0043] (2) Then the spinning solution is ultrasonicated for 4 hours in a water bath at room temperature; the spinning solution after ultrasonic is packed into a syringe, the receiver is set, and the electrospinning device is built. The distance between the nozzle and the receiving receiver is 10- 20cm;

[0044] (3) Electrospinning is carried out under the conditions of 12kv voltage and spinning solution flow rate of 2.0-4.0mL / h (see image 3 , 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com