Cross-linking modified polyethyleneimine solid electrolyte and application thereof

A technology of solid electrolyte and polyethyleneimine, which is applied in the direction of solid electrolyte, composite electrolyte, non-aqueous electrolyte, etc., can solve the problems of poor thermal stability, poor film-forming property, and low conductivity, so as to reduce the internal resistance of the battery and improve the cost. Membrane properties, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

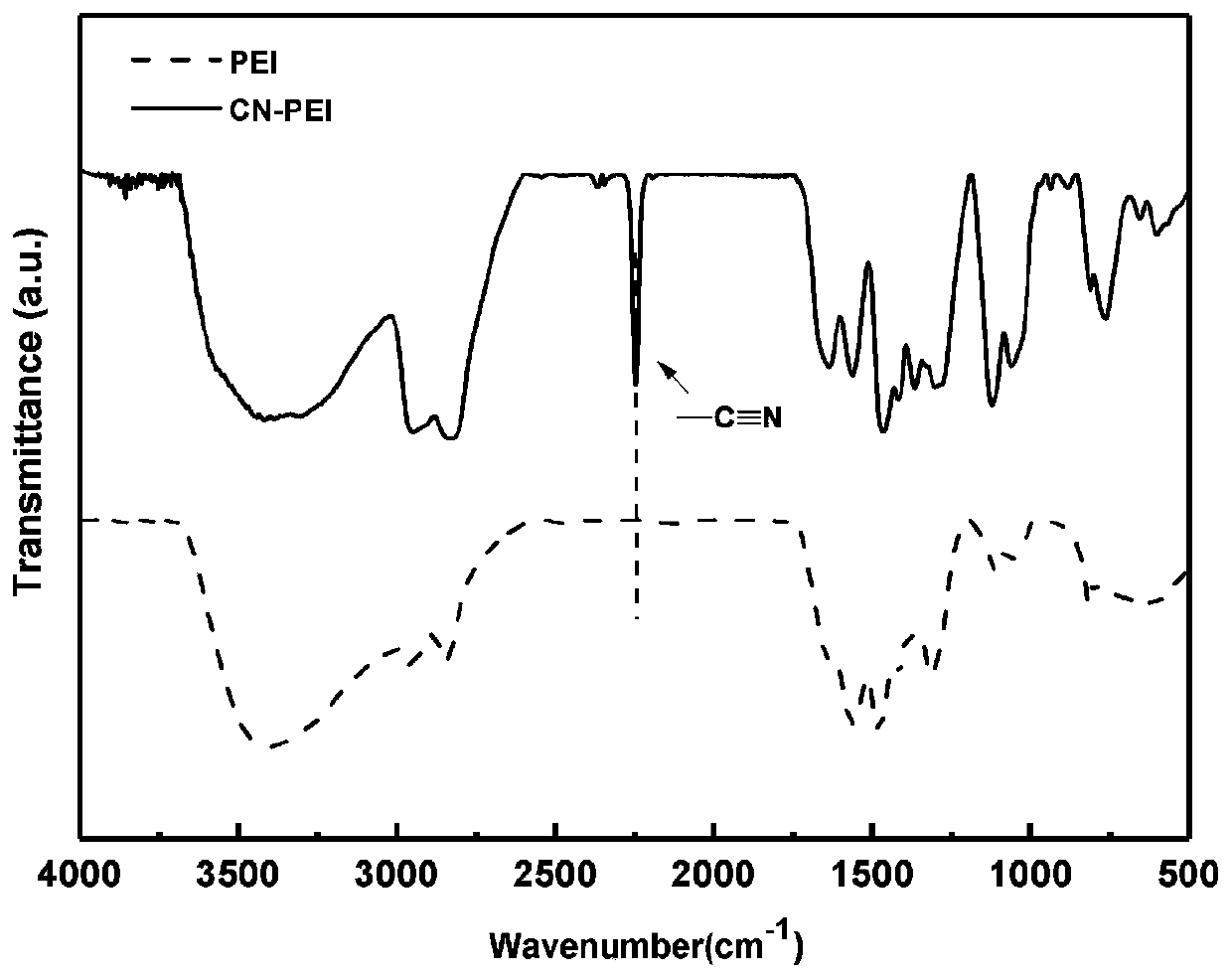

[0044] Step (1) Synthesis of modified polyethyleneimine: 4 g of polyethyleneimine and 4.45 g of absolute ethanol were weighed with an electronic balance. Wherein, polyethyleneimine is polyethyleneimine aqueous solution, and the number average molecular weight is 20000. The polyethyleneimine and absolute ethanol were placed in a three-neck flask with a vent valve, wherein a condenser was connected to the three-necked flask and a thermometer was inserted to form a reactor. Pass argon into the flask and stir with a magnetic stirrer for more than 2 hours. After stirring evenly, add 0.45g of acrylonitrile with a syringe, raise the temperature in the reaction flask to 60°C, stir at 500rmp, and react for 12 hours to obtain acrylonitrile-modified Polyethyleneimine (CN-PEI);

[0045] Step (2) preparation of crosslinked polymer solid state electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modification ratio of polye...

Embodiment 2

[0058] Step (1) is the same as step (1) of embodiment 1, the difference lies in step (2).

[0059] Step (2) preparation of crosslinked polymer solid state electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modification ratio of polyethyleneimine is 1:2, lithium salt ( The quality of LiTFSI) is 10% of the total mass of modified polyethyleneimine, lithium salt and crosslinking agent, and the quality of crosslinking agent (Aa) is 8% of the total mass of modified polyethyleneimine, lithium salt and crosslinking agent %. And stir evenly with a magnetic stirrer at room temperature; pour the mixed solution into a polytetrafluoroethylene mold, and perform drying and crosslinking under a certain heating program. The heating program is: first gradually heat up to 85°C, the heating rate is 5°C / h, and finally transferred to a vacuum drying oven, the temperature is 110°C, and the holding time is 2h. After cooling, the ...

Embodiment 3

[0064] Step (1) Synthesis of modified polyethyleneimine: Weigh 4 g of polyethyleneimine and 4.45 g of deionized water with an electronic balance, wherein the polyethyleneimine is an aqueous solution of polyethyleneimine with a number average molecular weight of 5000. Put polyethyleneimine and deionized water in a three-necked bottle with a vent valve, connect a condenser tube to the three-necked bottle and insert a thermometer to form a reactor. After passing through argon and stirring for 2 hours, add 0.65 g of acrylic acid with a syringe, increase the temperature in the reaction bottle to 55 ° C, and continue stirring at a speed of 800 rpm for 10 hours to obtain acrylic acid-modified polyethyleneimine (N-CEPEI); The molar ratio of repeating units of ethyleneimine to modifying monomers is 1:3.

[0065] Step (2) preparation of cross-linked polymer solid electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com