Dehydrogenation catalyst as well as preparation method and application thereof

A technology of dehydrogenation catalyst and alumina, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of precious metal loss and low specific surface area, and promote Effect of dispersion, high reactivity, ability to suppress halogen poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

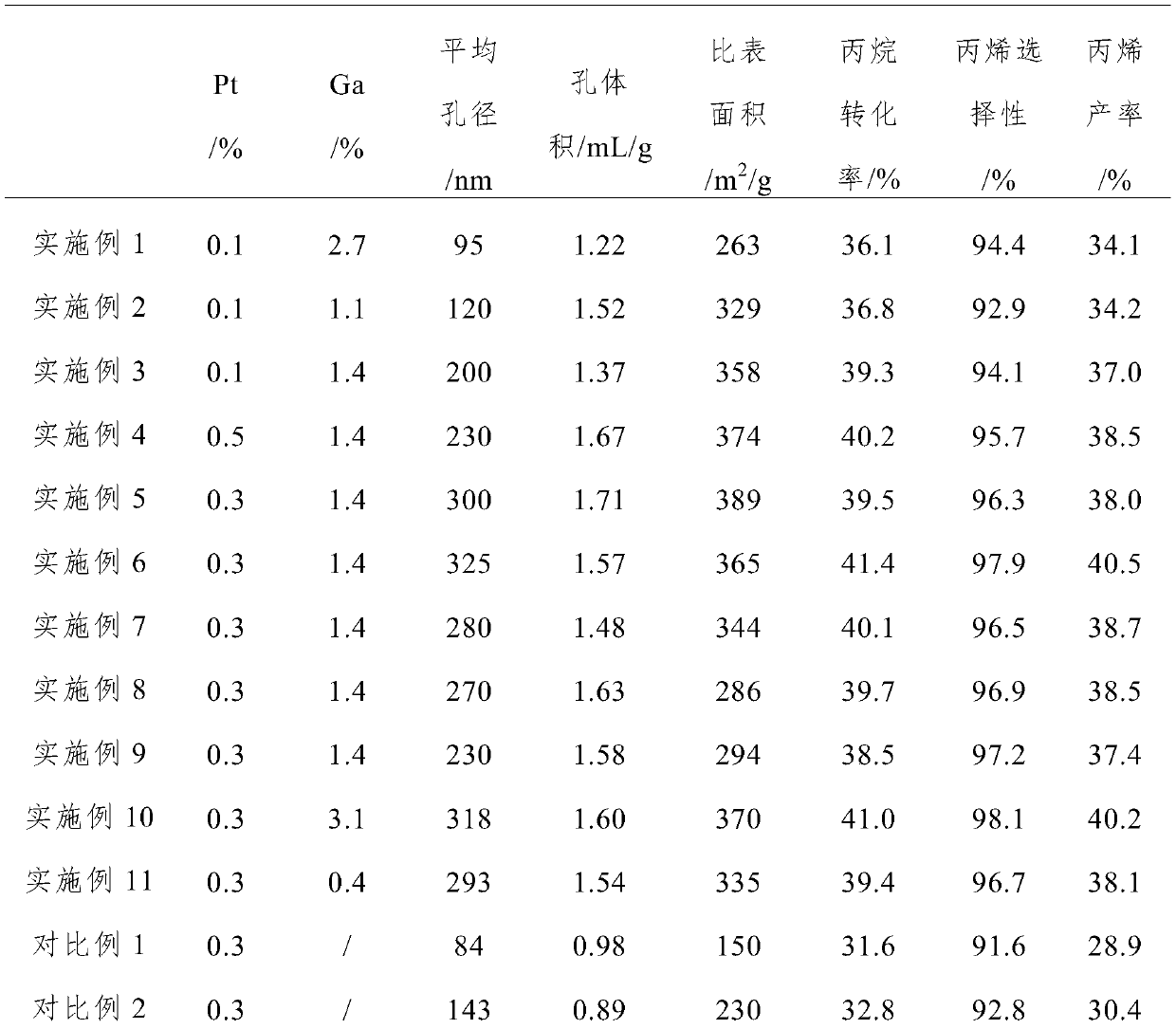

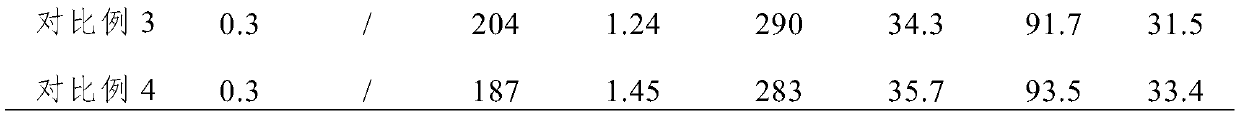

Embodiment 1

[0037] The preparation of Ga-containing perovskite includes the following steps:

[0038] Step 1, dissolving the raw materials in lye, and continuing to add lye until the pH is 9.0 to obtain a Ga-containing perovskite precursor; the lye is ammonia water with a mass concentration of 10%; the raw materials are lanthanum nitrate and nitric acid Strontium, cobalt nitrate and gallium nitrate, the ratio of the amount of substance of the lanthanum nitrate, strontium nitrate, cobalt nitrate and gallium nitrate is 5:5:3:7;

[0039] Step 2, the Ga-containing perovskite precursor described in step 1 is sequentially dried, roasted, and ground to obtain a molecular formula of La 0.5 Sr 0.5 co 0.3 Ga 0.7 o 3 Ga-containing perovskite; the drying temperature is 90°C, and the drying time is 10h; the roasting atmosphere is air atmosphere, the roasting temperature is 800°C, and the roasting time is 5h; the Ga-containing The particle size of the perovskite is 200 mesh.

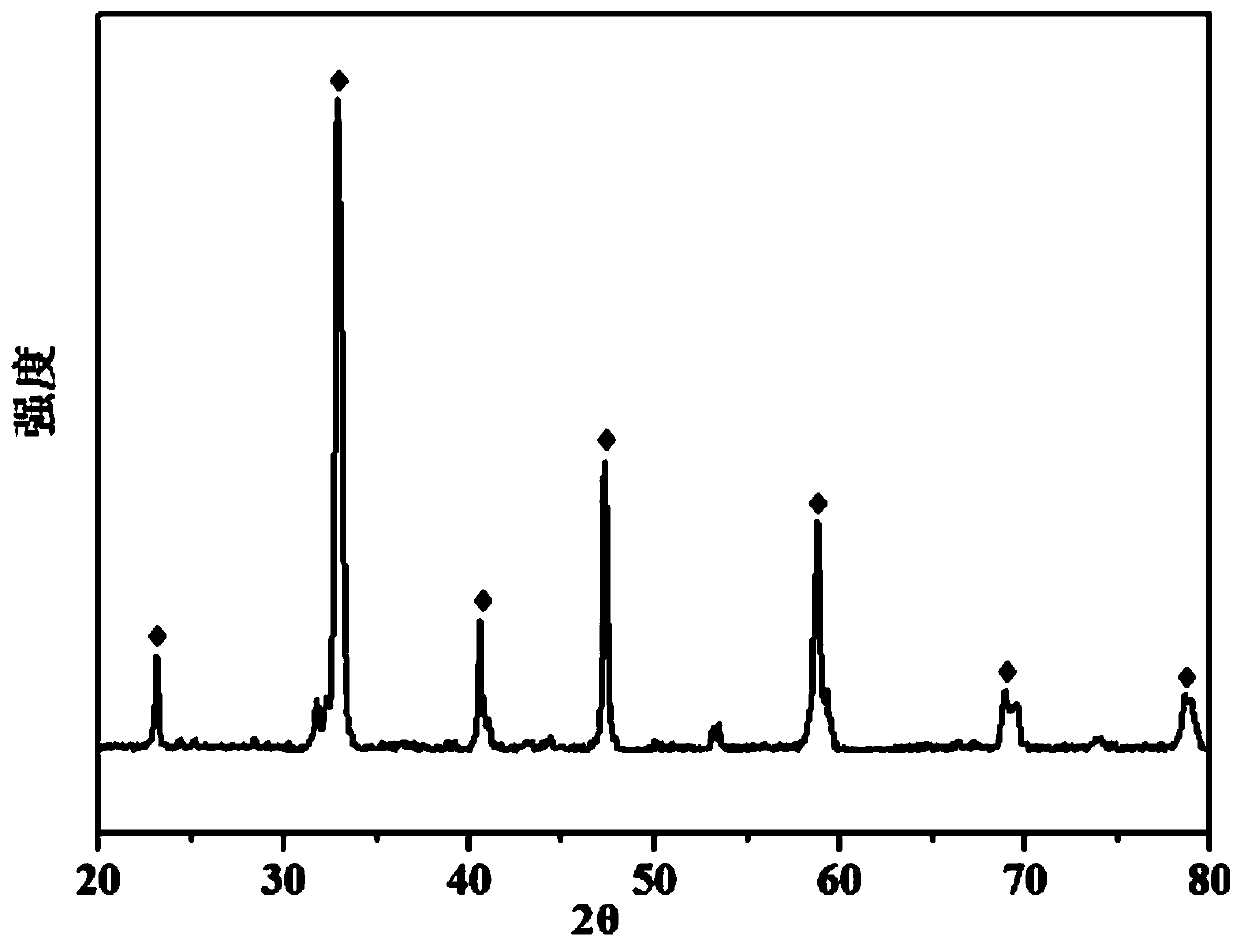

[0040] The XRD spec...

Embodiment 2

[0049] The preparation of Ga-containing perovskite includes the following steps:

[0050] Step 1, dissolving the raw materials in lye, and continuing to add lye until the pH is 10.5 to obtain a Ga-containing perovskite precursor; the lye is ammonia water with a mass concentration of 20%; the raw materials are lanthanum nitrate and nitric acid Strontium, cobalt nitrate and gallium nitrate, the ratio of the amount of substance of the lanthanum nitrate, strontium nitrate, cobalt nitrate and gallium nitrate is 5:5:3:7;

[0051] Step 2, the Ga-containing perovskite precursor described in step 1 is sequentially dried, roasted, and ground to obtain a molecular formula of La 0.5 Sr 0.5 co 0.3 Ga 0.7 o 3 Ga-containing perovskite; the drying temperature is 110°C, and the drying time is 15h; the roasting atmosphere is air atmosphere, the roasting temperature is 1000°C, and the roasting time is 10h; the Ga-containing The particle size of the perovskite is 300 mesh.

[0052] A method...

Embodiment 3

[0060] The preparation of Ga-containing perovskite includes the following steps:

[0061] Step 1, dissolving the raw materials in lye, and continuing to add lye until the pH is 9.5 to obtain a Ga-containing perovskite precursor; the lye is ammonia water with a mass concentration of 15%; the raw materials are lanthanum nitrate and nitric acid Strontium, cobalt nitrate and gallium nitrate, the ratio of the amount of substance of the lanthanum nitrate, strontium nitrate, cobalt nitrate and gallium nitrate is 5:5:3:7;

[0062] Step 2, the Ga-containing perovskite precursor described in step 1 is sequentially dried, roasted, and ground to obtain a molecular formula of La 0.5 Sr 0.5 co 0.3 Ga 0.7 o 3 Ga-containing perovskite; the drying temperature is 100°C, and the drying time is 12h; the roasting atmosphere is air atmosphere, the roasting temperature is 900°C, and the roasting time is 8h; the Ga-containing The particle size of perovskite is 250 mesh.

[0063] A method for pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com