Catalyst for hydrogen production by methanol reforming and preparation method thereof

A reforming hydrogen production and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen, etc., can solve the problems of low hydrogen production activity, poor stability, and easy production of by-product carbon monoxide, etc., to achieve stable reaction The effect of good performance and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

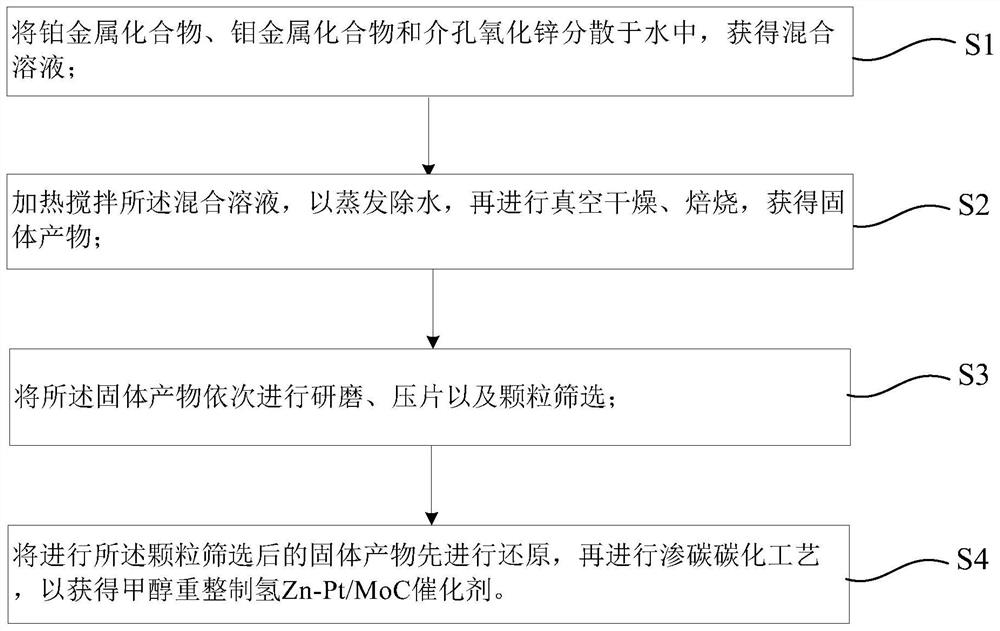

[0032] The invention provides a method for preparing a methanol reforming hydrogen production catalyst, such asfigure 1 As shown, the preparation method at least includes the following steps:

[0033] Firstly, step S1 is performed to disperse platinum metal compound, molybdenum metal compound and mesoporous zinc oxide in water to obtain a mixed solution.

[0034] As an example, in this step, the platinum metal compound includes one or more combinations of ammonium hexachloroplatinate, chloroplatinic acid, platinum dichloride, etc., and the platinum content of the platinum metal compound accounts for the mass of the catalyst The fraction is between 0.01wt% and 5.0wt%. For example, the platinum content of the platinum metal compound can be 0.01wt%, 0.05wt%, 0.1wt%, 0.5wt%, 1.0wt%, 1.5wt%, 2.0wt%, 3.0wt% in the mass fraction of the catalyst , 4.0wt%, 5.0wt% and so on. When determining the mass of the required catalyst, the mass fraction of platinum in the catalyst can be used t...

Embodiment 1

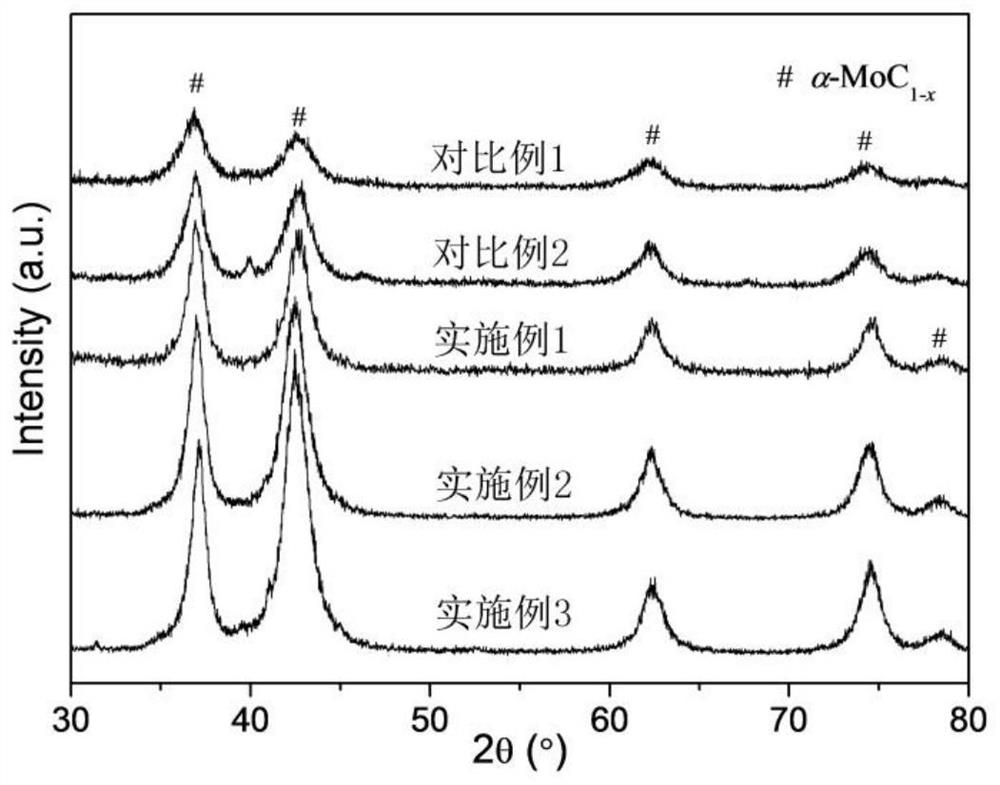

[0053] Embodiment 1: the preparation of Zn-Pt / MoC catalyst

[0054] Accurately weigh 53mg of chloroplatinic acid, 1230mg of ammonium molybdate, and 50mg of mesoporous zinc oxide and dissolve them in 5mL of water; then ultrasonically disperse them at a frequency of 120kHz for 2h. Then the mixed solution was placed in a 60°C water bath and stirred to remove most of the water solvent; the obtained sample was placed in a vacuum drying oven to dry at 80°C for 24 hours, then roasted at 500°C for 4 hours, ground, pressed into tablets, and granulated after screening, then put the sample into Tube furnace; first pass 5% H 2 / Ar mixed gas was programmed to heat up to 350°C and kept constant for 2h, then 10% CH 4 / H 2 The temperature of the mixed gas was raised to 750 °C and kept for 3 hours to carbonize the sample. After the temperature of the sample dropped to room temperature, 1% O 2 / Ar mixed gas is passivated, finally obtains embodiment 1 catalyst; The present invention carries o...

Embodiment 2

[0055] Embodiment 2: the preparation of Zn-Pt / MoC catalyst

[0056]Accurately weigh 53mg of chloroplatinic acid, 1230mg of ammonium molybdate, and 100mg of mesoporous zinc oxide and dissolve them in 5mL of water; then ultrasonically disperse them at a frequency of 120kHz for 2h, move the resulting solution to a 60°C water bath and stir for 48h, and then ultrasonically disperse for 4h again. Then the mixed solution was placed in a 60°C water bath and stirred to remove most of the water solvent; the obtained sample was placed in a vacuum drying oven to dry at 80°C for 24 hours, then roasted at 500°C for 4 hours, ground, pressed into tablets, and granulated after screening, then put the sample into Tube furnace; first pass 5% H 2 / Ar mixed gas was programmed to heat up to 350°C and kept constant for 2h, then 10% CH 4 / H 2 The temperature of the mixed gas was raised to 750 °C and kept for 3 hours to carbonize the sample. After the temperature of the sample dropped to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com