Hydrothermal carbonization method of sludge

A technology of hydrothermal carbonization and sludge water, applied in the direction of oxidation treatment of sludge, pyrolysis treatment of sludge, etc., can solve the problems of harming the health of the staff, effectively removing and purifying a large amount of facility investment, and poor public acceptability, etc., to achieve The Effect of Harmless Treatment of Sludge Carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

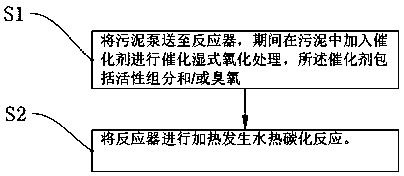

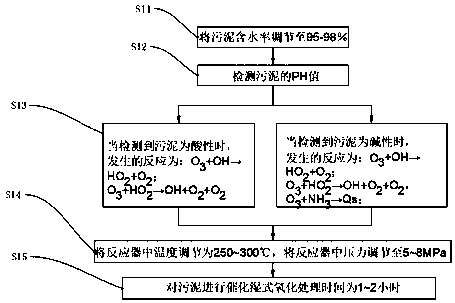

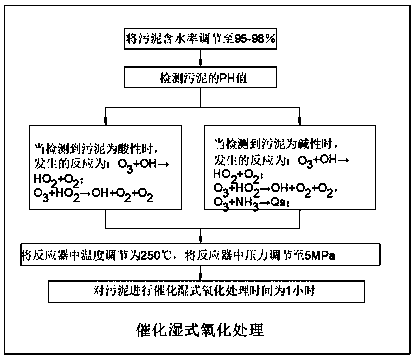

[0037] A method for hydrothermal carbonization of sludge, comprising the steps of:

[0038] S1, pumping the sludge to the reactor, during which a catalyst is added to the sludge for catalytic wet oxidation treatment, the catalyst includes active components and / or ozone;

[0039] S2. Heating the reactor to generate a hydrothermal carbonization reaction.

[0040] Wet oxidation is an effective water treatment technology for toxic, harmful and high-concentration organic wastewater. Through wet oxidation treatment, the sludge is passed through a reactor equipped with a catalyst with high-efficiency oxidation performance, and the organic matter and substances containing N, S and other substances can be catalyzed and oxidized into CO 2 , H 2 O and N 2 , SO 4 and other harmless substances are discharged, thereby removing the volatile suspended matter in the sludge. In the process, the ammonia nitrogen contained in the sludge is catalyzed and oxidized by ozone, active components, ...

Embodiment 2

[0066] A method for hydrothermal carbonization of sludge, comprising the steps of:

[0067] S1. Pumping the sludge to the reactor, during which a catalyst is added to the sludge, and the catalyst includes active components and / or ozone for catalytic wet oxidation treatment;

[0068] S2. Heating the reactor to generate a hydrothermal carbonization reaction.

[0069] As a further improvement to the above technical solution, the mass ratio of catalyst to sludge in step S1 is 1:30.

[0070] As a further improvement to the above technical solution, in step S1, the catalyst is Fe 2 O 3 , CuO, MnO 2 Or a mixture of one or more active components in ZnO.

[0071] As a further improvement to the above technical scheme, the mixture includes Fe 2 O 3 , CuO and MnO2 various mixtures are mixed according to the mass ratio of 4:3:3.

[0072] It can be understood that if only CuO, MnO2 and ZnO are contained, the mass ratio is 3:3:1, and other similar cases are handled similarly.

[007...

Embodiment 3

[0085] In step S1, a catalyst is added to the sludge, wherein the mass ratio of the catalyst to the sludge is 2.5:30; at the same time, Fe 2 O 3 As an active component, it is used to catalyze the catalyst of wet oxidation treatment.

[0086] In step S14, the temperature of the reactor is adjusted to 280° C., and the pressure is adjusted to 6.5 MPa;

[0087] In step S15, the sludge is subjected to catalytic wet oxidation treatment for 1.5 hours;

[0088] In step S23, the temperature in the reactor is adjusted to 180° C., and the pressure in the reactor is adjusted to 1.8 MPa;

[0089] In step S24, the hydrothermal carbonization reaction time is 5.5 hours to obtain a carbonized product.

[0090] S25, performing solid-liquid separation on the carbonized product obtained in step S24, to obtain biochar and liquid phase product respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com