Compound microorganism coated long-acting improvement fertilizer for saline-alkaline land and preparation method

A technology of compound microorganisms and compound microbial agents, applied in the direction of layered/coated fertilizers, fertilizer forms, fertilizer mixtures, etc., can solve the problems of short action time, difficult application, high cost, etc., to reduce alkalinity and promote root growth , enhance the effect of disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

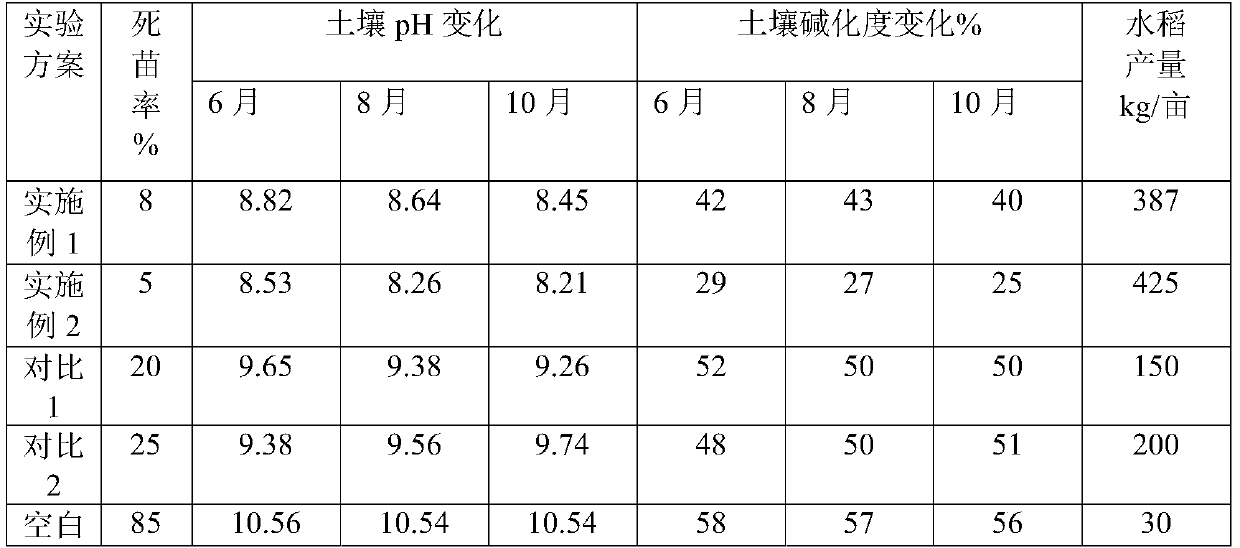

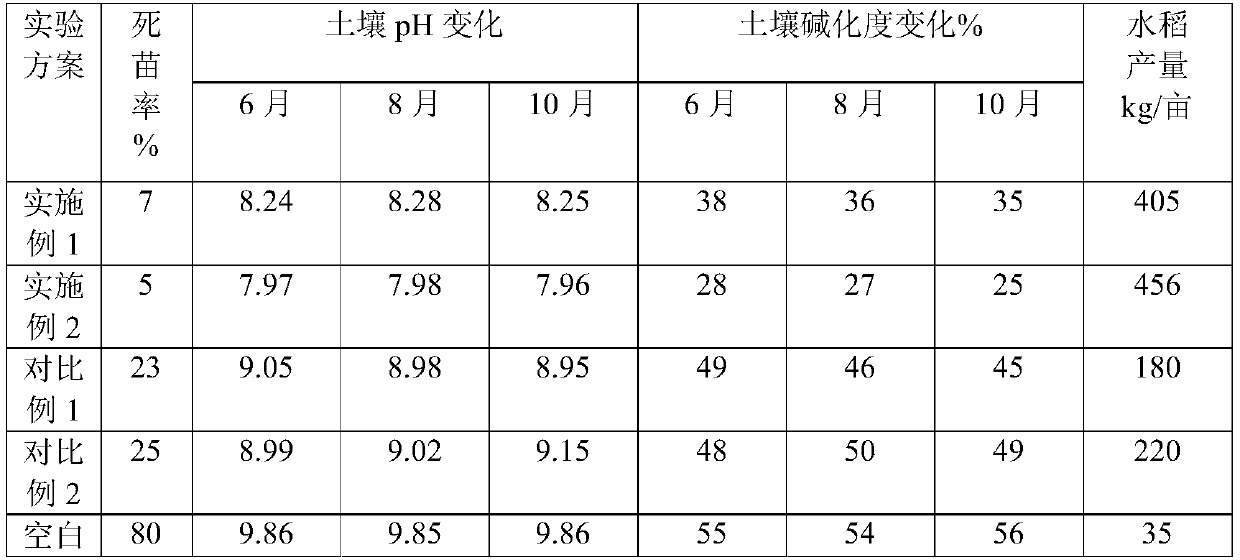

Examples

Embodiment 1

[0033] Compound microbial coating type long-acting saline-alkali land improvement fertilizer is prepared according to the following steps:

[0034] 1) First soak biochar in hydrochloric acid solution, wherein the volume ratio of biochar to hydrochloric acid solution is 1:3.5, and the concentration of hydrochloric acid solution is 0.025mol L -1 , The soaking time is 25 hours to obtain the acid-modified material, and then the acid-modified material is dissolved in the organic solvent acetone, wherein the volume ratio of the acid-modified material:organic solvent-acetone is 1:2.

[0035]2) In parts by weight, 100 parts of acid improving material, 10 parts of peat, 10 parts of humus, 10 parts of vermiculite, 10 parts of urea, 1 part of calcium, 0.5 part of magnesium, 0.01 part of iron, 0.05 part of manganese, 0.01 part of zinc , 0.01 part of silicon, mechanically mixed by a stirring pump, stirring time 15 hours, stirring power 7.5KW, put it on a rolling disc granulator, and obtain...

Embodiment 2

[0040] Compound microbial coating type long-acting saline-alkali land improvement fertilizer is prepared according to the following steps:

[0041] 1) First soak the phosphate rock powder in the hydrochloric acid solution, wherein the volume ratio of the phosphate rock powder to the hydrochloric acid solution is 1:1.5, and the concentration of the hydrochloric acid solution is 0.005mol L -1 , Soak for 20 hours to obtain the acid-modified material, and then dissolve the acid-modified material in the organic solvent acetone, wherein the acid-modified material:organic solvent-acetone volume ratio is 1:2.

[0042] 2) In parts by weight, 100 parts of acid modified materials, 20 parts of peat, 10 parts of humus, 10 parts of desulfurized gypsum, 10 parts of ammonium sulfate, 1 part of calcium, 0.5 part of magnesium, 0.02 part of iron, 0.01 part of boron powder, 0.005 parts of molybdenum and 0.01 parts of silicon are mechanically mixed by a stirring pump for 20 hours, with a stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com