Biodegradable PVA melt-spinning resin and application thereof

A technology of melt spinning and biodegradation, which is applied in the direction of melt spinning, conjugated synthetic polymer rayon, rayon manufacturing, etc. Instability and other problems, to achieve the effect of low production cost, small footprint, and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 15 parts of pentaerythritol, 15 parts of 1,4-butanediol, 10 parts of diethylene glycol, and 25 parts of deionized water into the reaction kettle, stir evenly, add 35 parts of propylene oxide dropwise, and add 0.015 parts of phosphoric acid catalyst The addition reaction is carried out, the rotation speed is 80-100 rpm, the stirring time is 100-120 minutes, and the temperature is 60-85° C. to obtain the addition reaction product 1.

[0026] 20 parts of PVA0599, 40 parts of PVA1299, 10 parts of the addition reaction product of Example 1, 15 parts of glycerol, 10 parts of polyglycerol 6, 5 parts of deionized water, 1-butyl-3-methylimidazole 1.5 parts of tetrafluoroborate, 1.0 parts of dodecyl sultaine, anatase TiO 2 2.0 parts, 0.45 parts of zinc stearate, 1.0 parts of oleic acid amide, 1.5 parts of Dupont FSO-100, 0.4 parts of antioxidant 10100, 0.5 parts of antioxidant 300, SiO 2 0.2 parts were put into the high-speed mixer, heated while stirring, pre-plasticized a...

Embodiment 2

[0029] Add 25 parts of glyceryl monoacetate, 25 parts of glyceryl diacetate, 25 parts of glyceryl triacetate, and 25 parts of glycerol into the reaction kettle and stir evenly, add 0.01 part of phosphoric acid catalyst for addition reaction, and the speed is 80-100 rotation per minute, the stirring time is 100-120 minutes, and the temperature is 60-85° C. to obtain the addition reaction product 2.

[0030] 20 parts of PVA0899, 40 parts of PVA1799, 15 parts of the addition reaction product of Example 2, 10 parts of glycerol, 10 parts of PEG800, 5 parts of deionized water, 1-butyl-3-methylimidazole chloride , 1.5 parts, 1.0 parts of dodecyl sultaine, anatase TiO 2 2.0 parts, zinc stearate 0.45 parts, solution amide 1.5 parts, DuPont FS-31 1.5 parts antioxidant 1010 0.6 parts, antioxidant 300 / 0.3 parts, SiO 2 / 0.5 parts, put them into the high-speed mixer, heat while stirring, pre-plasticize at 40°C-120°C / 40min, leave it for 24 hours, and then put it into the granulator for gra...

Embodiment 3

[0033] 20 parts of PVA0599, 40 parts of PVA2099, 25 parts of the addition reaction product of Example 2, 5 parts of glycerol, 5 parts of PEG2000, 5 parts of deionized water, 1-butyl-3-methylimididine tetrafluoro 1.0 parts of borate, 1.0 parts of 1-butyl-3-methylimidazine chloride, 1.0 parts of dodecyl sultaine, anatase TiO 2 2.0 parts, zinc stearate 0.45 parts, oleic acid amide 1.0 parts, DuPont FSO-100 1.5 parts, antioxidant 1010 0.6 parts, antioxidant 300 0.3 parts, SiO 2 0.5 parts were put into the high-speed mixer, heated while stirring, pre-plasticized at 40°C-120°C / 40min, left for 24 hours, and then put into the granulator for granulation to obtain biodegradable PVA melt spinning resin.

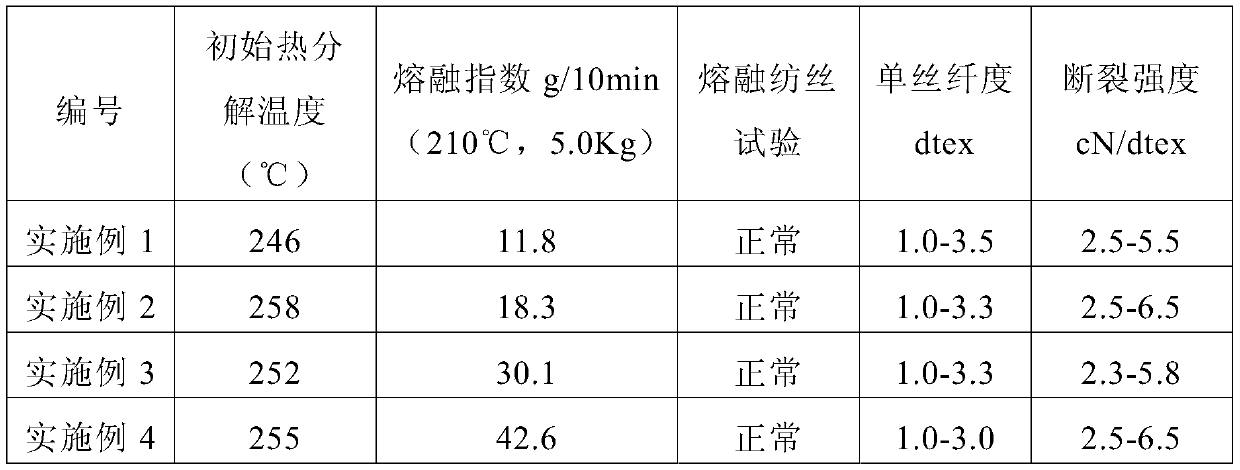

[0034] The biodegradable PVA melt-spinning resin was used for trial spinning on a single-head spinning machine, and the performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com