Preparation method for zinc oxide nanoflower/nanogold composite based temperature sensitive imprinted polymer

A zinc oxide nanometer, imprinted polymer technology, applied in chemical instruments and methods, other chemical processes, electrolytic organic material coating, etc., to achieve the effect of promoting electron transfer ability, increasing electrode surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

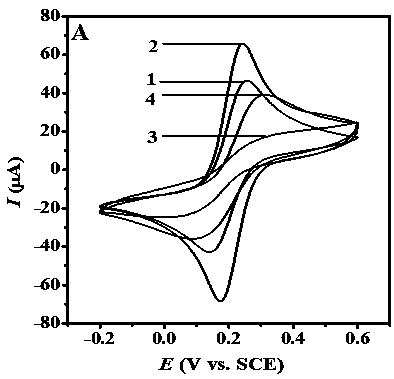

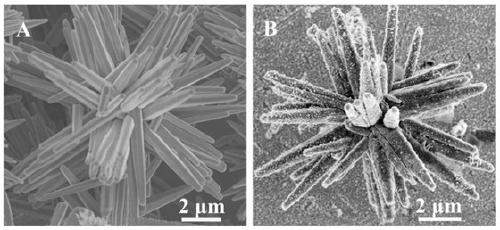

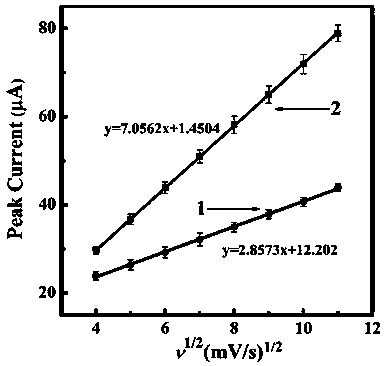

[0020] a. Dissolve 2 mmoL of zinc acetate dehydrate in 30 mL of water under vigorous magnetic stirring, add 7 mL of ethanolamine dropwise, stir for 15 min, then transfer to a stainless steel autoclave, react at 150 °C for 12 h, cool, and collect the product And washed 5 times with ultrapure water and ethanol respectively, put them into a drying oven and dried at 80°C for 2 h to obtain zinc oxide nanoflowers; mix 2 mg zinc oxide nanoflowers with 2 mL ultrapure water to obtain zinc oxide nanoflower suspensions The solution was drip-coated on the treated bare gold electrode to obtain the ZnO nanoflower modified electrode; then the ZnO nanoflower modified electrode was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum wire was used as the counter electrode. The electrode system was placed in a solution containing 1% HAuCl 4 solution, and electrodeposited at a constant potential of -0.9 V for 200 s to prepare ZnO na...

Embodiment 2

[0036] a. Dissolve 1mmoL of zinc acetate dehydrate in 30mL of water under vigorous magnetic stirring, add 3 mL of ethanolamine dropwise, stir for 15min, then transfer to a stainless steel autoclave, react at 150°C for 10h, cool, collect the product and use supernatant Wash with pure water and ethanol for 5 times, put them in a drying oven and dry at 80°C for 2 h to obtain zinc oxide nanoflowers; mix 2 mg of zinc oxide nanoflowers with 2 mL of ultrapure water to obtain a suspension of zinc oxide nanoflowers, Drop-coated onto the treated bare gold electrode to obtain a zinc oxide nanoflower modified electrode; then the zinc oxide nanoflower modified electrode was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum wire was used as the counter electrode. placed in 1% HAuCl 4 solution, and electrodeposited at a constant potential of -0.9 V for 200 s to prepare ZnO nanoflower / nanogold composite modified electrode;

...

Embodiment 3

[0039] a. Dissolve 4mmoL of zinc acetate dehydrate in 30mL of water under vigorous magnetic stirring, add 15 mL of ethanolamine dropwise, stir for 15min, then transfer to a stainless steel autoclave, react at 150°C for 14h, cool, collect the product and use supernatant Wash with pure water and ethanol 5 times respectively, put them in a drying oven and dry at 80°C for 2 h to obtain zinc oxide nanoflowers; mix 2 mg of zinc oxide nanoflowers with 2 mL of ultrapure water to obtain a suspension of zinc oxide nanoflowers, drop coated on the treated bare gold electrode to obtain the zinc oxide nanoflower modified electrode; then the zinc oxide nanoflower modified electrode was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum wire was used as the counter electrode, and the three-electrode system was placed containing 1% HAuCl 4 solution, and electrodeposited at a constant potential of -0.9 V for 200 s to prepare ZnO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com