Glass fiber reinforced plastic septic tank and production method thereof

A kind of glass tempering, septic tank technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

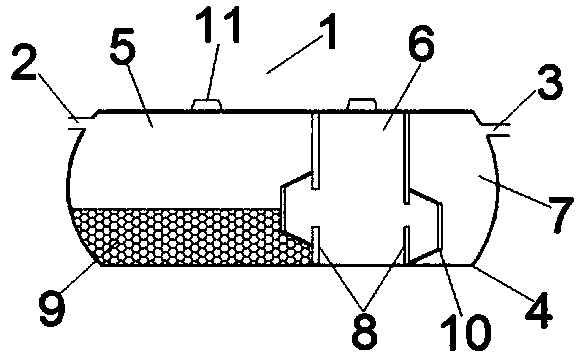

[0026] see figure 1 , the present invention provides a technical solution: a glass reinforced plastic septic tank, comprising a septic tank body 1, the septic tank body 1 is composed of a sewage inlet 2, a sewage discharge port 3 and a tank body 4; the tank body 4 The left and right ends of the tank are provided with a sewage inlet 2 and a sewage outlet 3; the interior of the tank body 4 is divided into three inner cavities by glass fiber reinforced plastics 8; the three inner cavities are successively filter chamber 5 and static chamber from left to right 6 and a clarification chamber 7; the bottom of the filter chamber 5 is provided with a biological filler 9, and the biological filler 9 is an anaerobic sludge layer; the glass fiber reinforced plastics 8 on the left and right sides of the static chamber 6 are provided with gaps; and A filter screen 10 is provided at the gap; a cleaning opening 11 is provided on the top of the filter chamber 5 and the static chamber 6 .

Embodiment 2

[0028] A kind of FRP septic tank proposed by the present invention, its raw material comprises by weight: 32 parts of methyl benzoate, 10 parts of phthalic anhydride, 8 parts of glutaric acid, 6 parts of fumaric acid, 3 parts of castor oil 13 parts of neopentyl glycol, 10 parts of styrene, 7 parts of methyl methacrylate, 2 parts of diallyl phthalate, 0.5 parts of polymerization inhibitor, 3 parts of polyvinyl acetate, 24 parts of inorganic filler , 0.4 parts of antioxidant, 5 parts of curing agent, 5 parts of accelerator, 200 parts of glass fiber, and 5 parts of waste paper pulp; the particle diameter of the inorganic filler is 0.01≤D≤50 μm; wherein, the polymerization inhibitor is Hydroquinone, the inorganic filler is talcum powder, and the antioxidant is antioxidant 1076.

[0029] The present invention also proposes a preparation method for the above-mentioned FRP septic tank, comprising the following steps:

[0030] S1. Under the protection of nitrogen, add neopentyl glyco...

Embodiment 3

[0036] A kind of FRP septic tank proposed by the present invention, its raw material comprises by weight: 35 parts of methyl benzoate, 15 parts of phthalic anhydride, 12 parts of glutaric acid, 12 parts of fumaric acid, 2 parts of castor oil 8 parts of neopentyl glycol, 7 parts of styrene, 2 parts of methyl methacrylate, 1 part of diallyl phthalate, 0.1 part of polymerization inhibitor, 1 part of polyvinyl acetate, 10 parts of inorganic filler , 0.2 parts of antioxidant, 2 parts of curing agent, 4 parts of accelerator, 150 parts of glass fiber, 20 parts of waste paper pulp; the particle size of the inorganic filler is 0.01≤D≤50 μm; wherein, the polymerization inhibitor is benzene Diphenol, the inorganic filler is talcum powder, and the antioxidant is antioxidant 168.

[0037] The present invention also proposes a preparation method for the above-mentioned FRP septic tank, comprising the following steps:

[0038]S1. Under the protection of nitrogen, add neopentyl glycol and fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com