Thermal insulation type co-extrusion wood-plastic-carbon fiber composite board

A technology of carbon fiber and composite materials, applied in the direction of wood layered products, synthetic resin layered products, layered products, etc., can solve the problems of poor matrix resin compatibility, poor dispersion, high temperature, etc., to improve antistatic properties, Effect of improving weather resistance and increasing heat absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

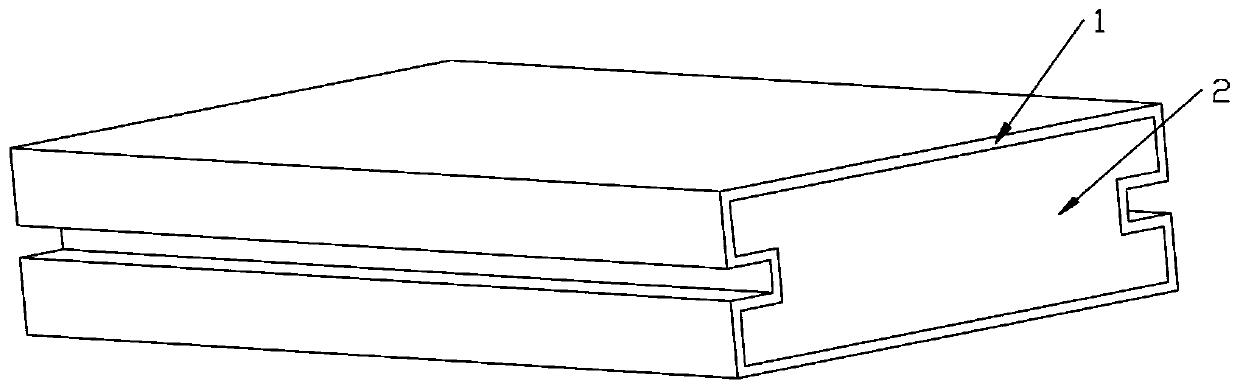

[0028] A thermal insulation type co-extruded wood-plastic carbon fiber composite board, including a surface layer and an inner layer, wherein,

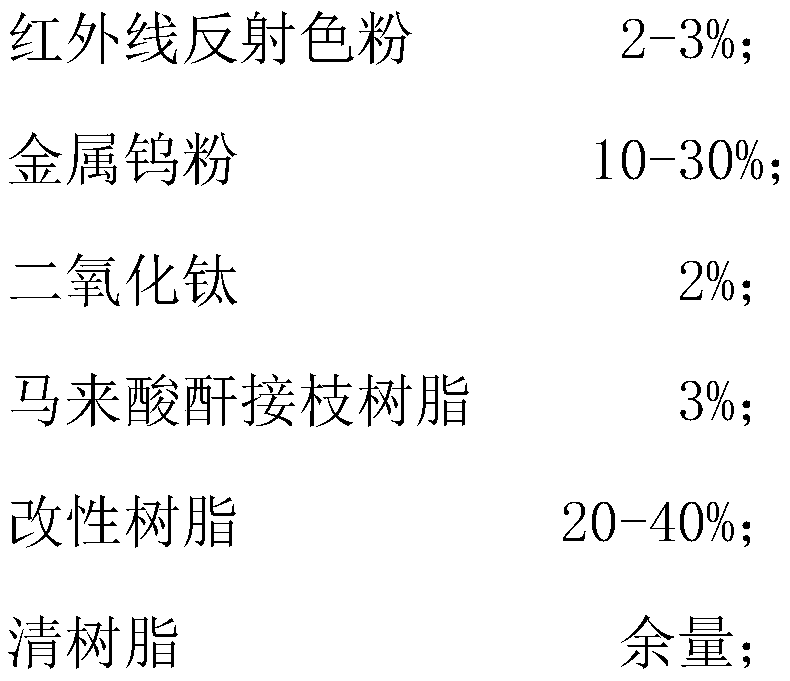

[0029] Surface formula consists of the following mass percentages:

[0030]

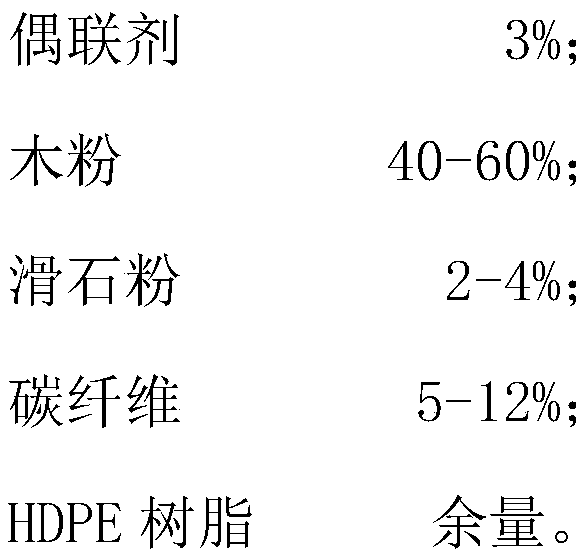

[0031] The inner layer formula is composed of the following mass percentages:

[0032]

[0033] Put the above-mentioned surface layer material and inner layer material into the high-mixing pot to 240°C, stir in the cold mixing pot, and pass the basic bar through the crushing machine to obtain the pellets of the surface layer material and the inner layer material. The two pellets are passed through the principle of co-extrusion The twin-screw extruder and the single-screw extruder are fed through the mold from two directions, and the surface layer of the stroke retaliates with the composite sheet of the inner layer. The airflow provided by the vacuum pump cools the product, and then the product is cut and shaped and the surface is drawn. Surface forms ...

Embodiment 2

[0035] A thermal insulation type co-extruded wood-plastic carbon fiber composite board, including a surface layer and an inner layer, wherein,

[0036] Surface formula consists of the following mass percentages:

[0037]

[0038] The inner layer formula is composed of the following mass percentages:

[0039]

[0040] Put the above-mentioned surface layer material and inner layer material into the high-mixing pot to 240°C, stir in the cold mixing pot, and pass the basic bar through the crushing machine to obtain the pellets of the surface layer material and the inner layer material. The two pellets are passed through the principle of co-extrusion The twin-screw extruder and the single-screw extruder are fed through the mold from two directions, and the surface layer of the stroke retaliates with the composite sheet of the inner layer. The airflow provided by the vacuum pump cools the product, and then the product is cut and shaped and the surface is drawn. Surface forms ...

Embodiment 3

[0042] A thermal insulation type co-extruded wood-plastic carbon fiber composite board, including a surface layer and an inner layer, wherein,

[0043] Surface formula consists of the following mass percentages:

[0044]

[0045]

[0046] The inner layer formula is composed of the following mass percentages:

[0047]

[0048] Put the above-mentioned surface layer material and inner layer material into the high-mixing pot to 240°C, stir in the cold mixing pot, and pass the basic bar through the crushing machine to obtain the pellets of the surface layer material and the inner layer material. The two pellets are passed through the principle of co-extrusion The twin-screw extruder and the single-screw extruder are fed through the mold from two directions, and the surface layer of the stroke retaliates with the composite sheet of the inner layer. The airflow provided by the vacuum pump cools the product, and then the product is cut and shaped and the surface is drawn. Su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap