A kind of magnesium aluminum hydrotalcite for organosulfur catalysis and its preparation method and application

A magnesium-aluminum hydrotalcite and organic sulfur technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as poor crystallinity, achieve high crystallinity, simple and easy steps, regular and controllable morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

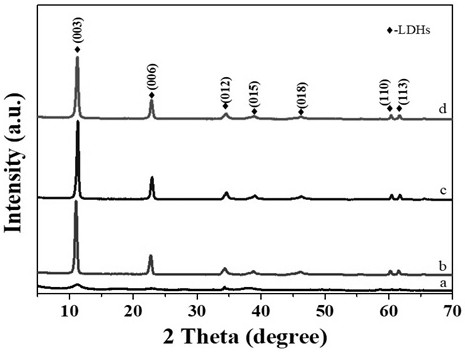

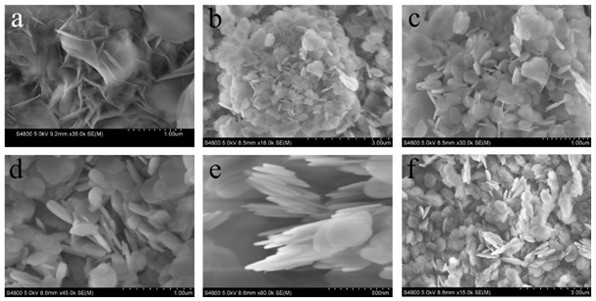

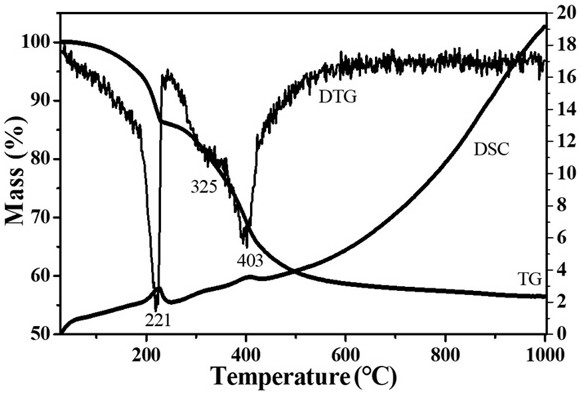

[0023] Example 1: 2.54 g of magnesium methoxide and 2 g of aluminum isopropoxide were weighed respectively, and then transferred to an agate mortar and ground manually for 5 minutes. After the mechanical mixing was completed, the mixed material was placed in a polytetrafluoroethylene lining of a hydrothermal kettle, and then 1ml of sodium bicarbonate solution (1 M) was added to react at 150 °C for 12 h. After the reaction was completed, the initial product was cooled to room temperature, and then the initial product was dried in an oven at 100 °C for 12 h. After natural cooling, the magnesium aluminum hydrotalcite for organosulfur catalysis was obtained, which was designated as catalyst A.

Embodiment 2

[0024] Example 2: 3.36 g of magnesium ethoxide and 2 g of aluminum isopropoxide were weighed respectively, and then transferred to an agate mortar and ground manually for 10 minutes. After the mechanical mixing was completed, the mixed material was placed in a polytetrafluoroethylene lining of a hydrothermal kettle, and then 3ml of sodium carbonate solution (1.2 M) was added to react at 120 °C for 6 h. After the reaction was completed, the initial product was cooled to room temperature, and then the initial product was dried in an oven at 100 °C for 12 h. After natural cooling, the magnesium aluminum hydrotalcite for organosulfur catalysis was obtained, which was designated as catalyst B.

Embodiment 3

[0025] Example 3: 3.36 g of magnesium ethoxide and 2 g of aluminum isopropoxide were weighed respectively, and then transferred to an agate mortar and ground manually for 30 minutes. After the mechanical mixing was completed, the mixed material was placed in a polytetrafluoroethylene lining of a hydrothermal kettle, and then 5ml of sodium carbonate solution (1 M) was added to react at 130 °C for 3 h. After the reaction was completed, it was cooled to room temperature to obtain the primary product, which was then dried in an oven at 80 °C for 24 h. After natural cooling, the magnesium aluminum hydrotalcite for organosulfur catalysis was obtained, which was designated as catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com