A kind of thermosensitive ruthenium carbene complex and its preparation method and application

A carbene complex and temperature-sensitive technology, which is applied in the field of ruthenium carbene complex and its preparation, can solve the problems that the catalyst cannot be stored for a long time, affects the final performance of the material, and the temperature-controlled catalyst is slow, so as to catalyze the temperature-controlled polymerization of olefins , broad industrial application prospects, the effect of less catalyst consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

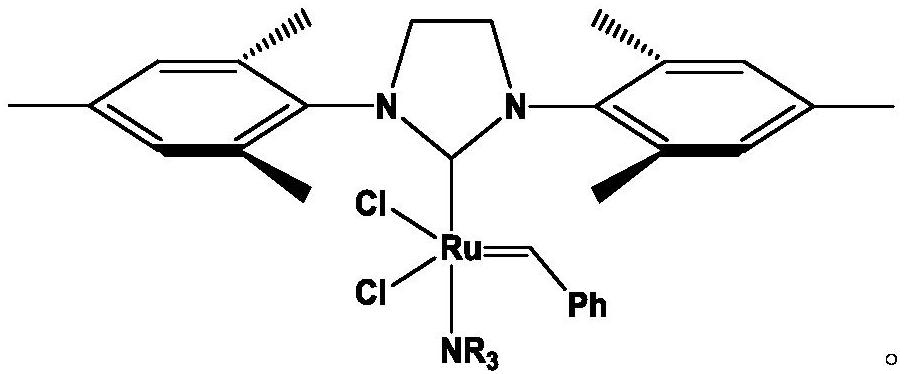

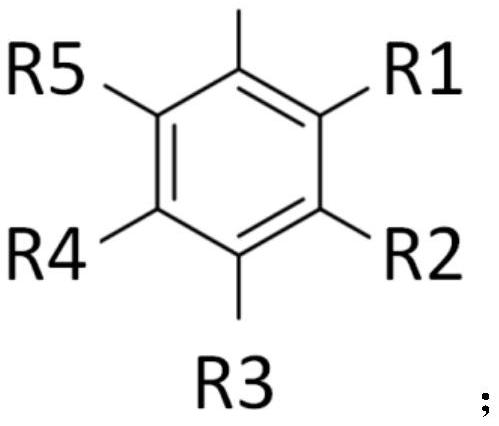

[0037] This embodiment is a preparation method of a temperature-sensitive ruthenium carbene complex, and its synthetic route is as follows:

[0038]

[0039]The specific preparation process is:

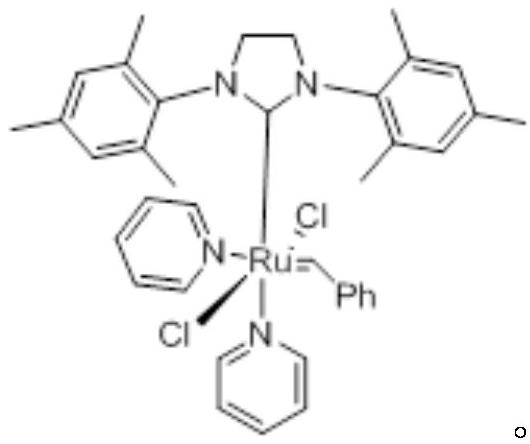

[0040] (1) Get 20.0g Grubbs second-generation catalyst to a 250mL flask, add 100mL pyridine (used as solvent and reactant), stir at room temperature for 24h, then obtain 16.0g Grubbs third-generation catalyst through separation and purification, yield 93%; : The preparation process of Grubbs third-generation catalyst refers to [Organometallics, 2001, 20, 5314-5318] literature.

[0041] The prepared Grubbs third-generation catalyst was characterized by nuclear magnetic resonance, and the detection data were as follows:

[0042] 1 H NMR (CDCl 3 )19.67(s,1H,CH=Ph),8.84(s,2H,pyridine),8.39(s,2H,pyridine),8.07(d,2H,ortho CH),7.15(t,1H,para CH), 6.83-6.04 (m, 9H, pyridine, Mes-CH), 3.37 (d, 4H, CH 2 CH 2 ),2.79(s,6H,Mes-CH 3 ),2.45(s,6H,Mes-CH 3 ),2.04(s,6H,Mes-CH 3 ).

[0043]...

Embodiment 2

[0051] In this implementation, the Grubbs third-generation catalyst obtained in step (1) in Example 1 was used to further prepare a temperature-sensitive ruthenium carbene complex, catalyst Cat.-2; and the prepared catalyst was used to catalyze 2,5-dimethyl- Polymerization of 2,4-hexadiene.

[0052] (1) Mix 1.0g Grubbs third-generation catalyst with 4.86gN(C 8 h 17 ) 3 (10.0 equivalents) was added to 5 mL of ethyl acetate solvent, and magnetically stirred at 40° C. for 12 h; after the reaction was completed, 1.04 g of catalyst Cat.-2 was obtained by separation, purification, and drying, with a catalyst yield of 82%.

[0053] Carry out nuclear magnetic resonance characterization of the catalyst Cat.-2 prepared, and the detection data are as follows:

[0054] 1 H NMR (CDCl 3 ) δ (ppm) = 0.88 (t, 9H, CH 2 -CH 3 ),1.26(t,36H,-CH 2 -),2.12(s,12H,Mes-CH 3 ),2.26(s,6H,Mes-CH 3 ),2.34(t,6H,N-CH 2 ),4.04(s,4H,N-CH 2 -CH 2 -N), 6.63(s, 4H, Mes-CH), 7.23(t, 2H, Ar-H), 7.54(t...

Embodiment 3

[0060] In this implementation, the third-generation Grubbs catalyst obtained in step (1) of Example 1 was used to further prepare a temperature-sensitive ruthenium carbene complex, catalyst Cat.-3; and the prepared catalyst was used to catalyze the polymerization of dicyclopentadiene.

[0061] (1) 1.0gGrubbs third generation catalyst and 18.95g N(C 16 h 33 ) 3 (20.0 equivalents) was added to 20 mL of ether solvent, and magnetically stirred at 60°C for 48 hours; after the reaction was completed, 1.19 g of catalyst Cat.-3 was obtained by separation, purification, and drying, with a yield of 69%.

[0062] The prepared Cat.-3 catalyst was characterized by nuclear magnetic resonance, and the detection data were as follows:

[0063] 1 H NMR (CDCl 3 ) δ (ppm) = 0.88 (t, 9H, CH 2 -CH 3 ),1.27(t,84H,-CH 2 -),2.12(s,12H,Mes-CH 3 ),2.26(s,6H,Mes-CH 3 ),2.34(t,6H,N-CH 2 ),4.04(s,4H,N-CH 2 -CH 2 -N), 6.63(s, 4H, Mes-CH), 7.23(t, 2H, Ar-H), 7.54(t, 1H, ArH), 7.75(d, 2H, Ar-H), 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com