A peelable temporary protective coating

A temporary protection and coating technology, applied in the field of coatings, can solve the problems of inconvenient use, environmental protection, and inability to reuse, etc., and achieve the effect of convenient use and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

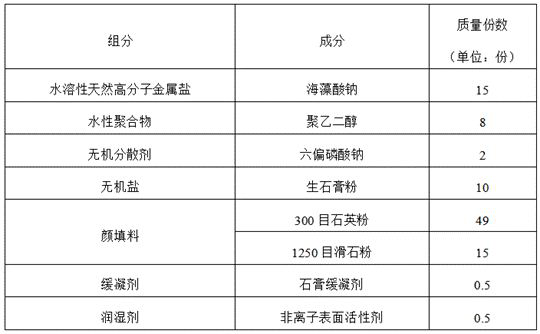

[0026] A strippable temporary protective coating, the formula table is as follows:

[0027]

[0028] The preparation method of the described strippable temporary protective coating comprises the following steps:

[0029] S1. Add polyethylene glycol and raw gypsum powder into the high-speed mixer and mix evenly to form a wet paste;

[0030] S2. Add 300-mesh quartz powder, 1250-mesh talcum powder, sodium hexametaphosphate, gypsum retarder, non-ionic surfactant, mix evenly at high speed, and it is in the form of a wet powder;

[0031] S3. Add sodium alginate and mix well.

Embodiment 2

[0033] A strippable temporary protective coating, the formula table is as follows:

[0034]

[0035] The preparation method of the described strippable temporary protective coating comprises the following steps:

[0036] S1. Add sorbitol into the container, start the high-speed disperser, and stir at medium speed;

[0037] S2. Add sodium hexametaphosphate, stir for 5 minutes;

[0038] S3. Add 800 mesh heavy calcium, washed kaolin, 1250 mesh talcum powder, and disperse at high speed for 15 minutes;

[0039] S4. Turn to medium speed, add starch, nonionic surfactant, defoamer, and stir evenly;

[0040] S5. Add sodium alginate and preservative, and mix evenly at low speed.

Embodiment 3

[0042] A strippable temporary protective coating, the formula table is as follows:

[0043]

[0044] The preparation method of the described strippable temporary protective coating comprises the following steps:

[0045] S1. Add tripolyglycerol into the container, start the high-speed disperser, and stir at a medium speed;

[0046] S2. Add sodium hexametaphosphate, stir for 5 minutes;

[0047] S3. Add 800-mesh heavy calcium, 300-mesh quartz powder, and 1250-mesh talcum powder, and disperse at high speed for 15 minutes;

[0048] S4. Turn to medium speed, add non-ionic surfactant, and stir evenly;

[0049] S5. Add sodium alginate and mix evenly at low speed.

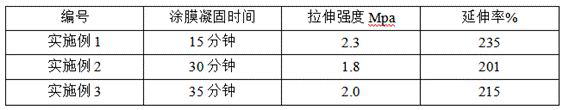

[0050] The following is the experimental verification data of the technical effect of the embodiment.

[0051] 1. Setting time, tensile strength, elongation test

[0052] 1. Test method: Example 1, Example 2, Example 3 and Comparative Example (a commercially available quick-drying temporary protective coating) were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com