Multifunctional textile finishing agent and preparing method and application thereof

A fabric finishing agent, multi-functional technology, applied in fiber treatment, textiles and papermaking, improved handle fibers, etc., can solve the problems of lack, fabric feel, air permeability and moisture permeability decline, etc., and achieve yellowing, softness and fluffy feel And the effect of water repellency and fluffy feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

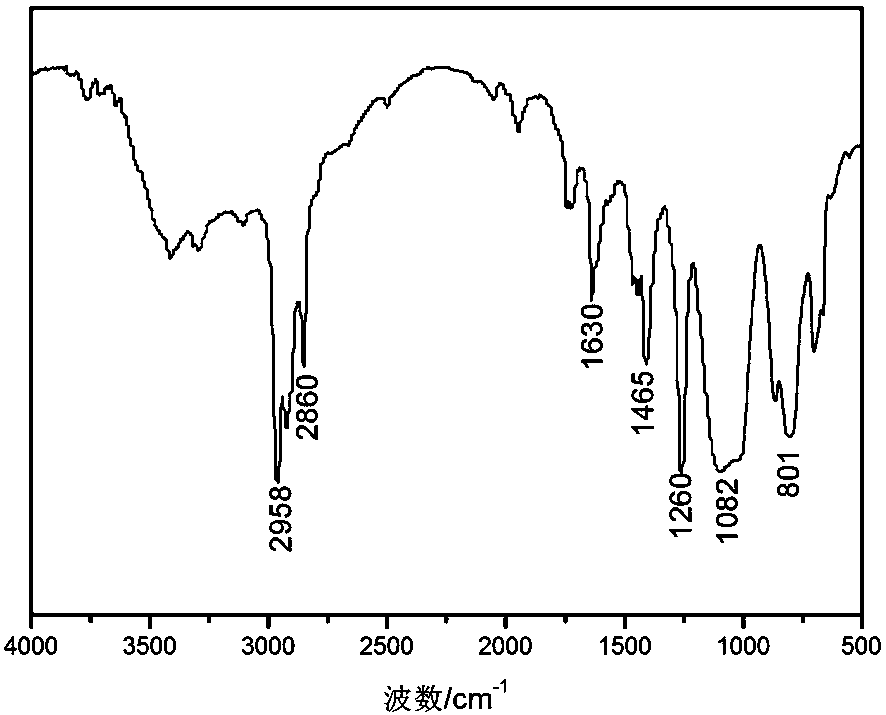

Embodiment 1

[0032] 1. Add 10g of epoxy double-head and 10g of dodecylamine into the first reaction vessel with a stirrer and condensing reflux device, turn on the condensing device and agitator, and start heating after nitrogen gas for 5 minutes, and the temperature rises The intermediate product I was obtained after reacting for 4 hours at 70°C.

[0033] 2. Add 8g of intermediate product I, 4g of γ-piperazinylpropylmethyldimethoxysilane and 100g of octamethylcyclotetrasiloxane into the second reaction vessel equipped with a stirrer, and turn on the stirrer. The temperature was raised to 70°C, 0.09g of tetramethylammonium hydroxide was added, and the temperature was continued to rise to 95°C. After 5 hours of reaction, the intermediate product II was obtained.

[0034] 3. Add 100g of intermediate product II, 2.1g of triethylamine and 32.6g of acetone into the third reaction vessel equipped with a stirrer and a dripping device, add 8.5g of dodecanoyl chloride into the dripping device, and ...

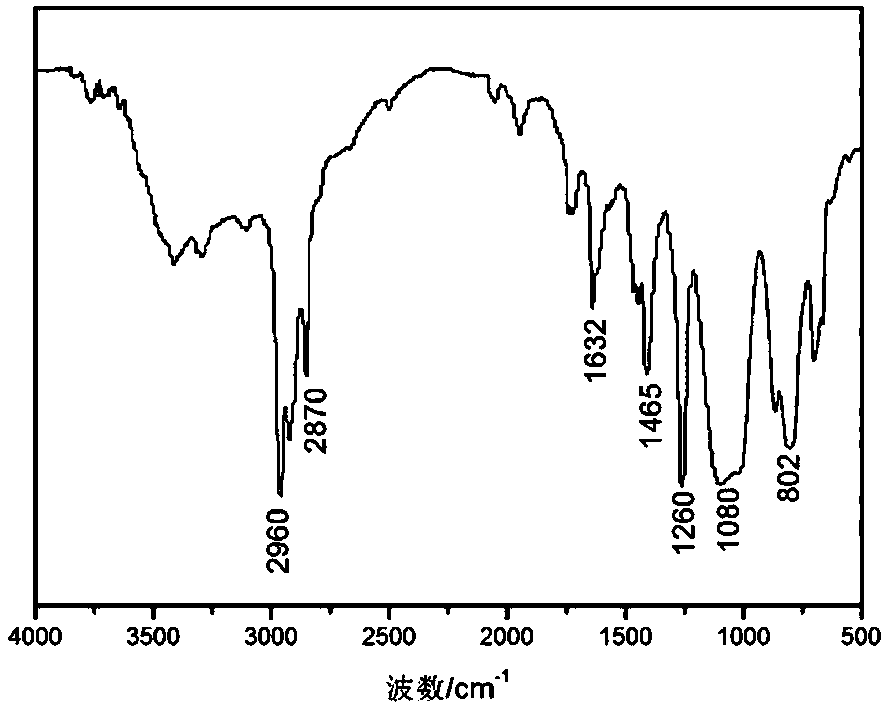

Embodiment 2

[0041] 1. Add 20g of epoxy double-head and 24g of tetradecylamine into the first reaction vessel with agitator and condensing reflux device, turn on the condensing device and agitator, and start heating after nitrogen gas for 7 minutes, and the temperature rises The intermediate product I was obtained after reacting for 4.5 hours at 75°C.

[0042] 2. Add 18g of intermediate product I, 8g of γ-piperazinylpropylmethyldimethoxysilane and 200g of octamethylcyclotetrasiloxane into the second reaction vessel equipped with a stirrer, and turn on the stirrer. The temperature was raised to 72°C, 0.2g of tetramethylammonium hydroxide was added, and the temperature was continued to rise to 97°C. After 5.5 hours of reaction, the intermediate product II was obtained.

[0043] 3. Add 205g of intermediate product II, 4.2g of triethylamine and 79.7g of acetone into the third reaction vessel equipped with a stirrer and a dripping device, add 22.8g of octadecanoyl chloride into the dripping dev...

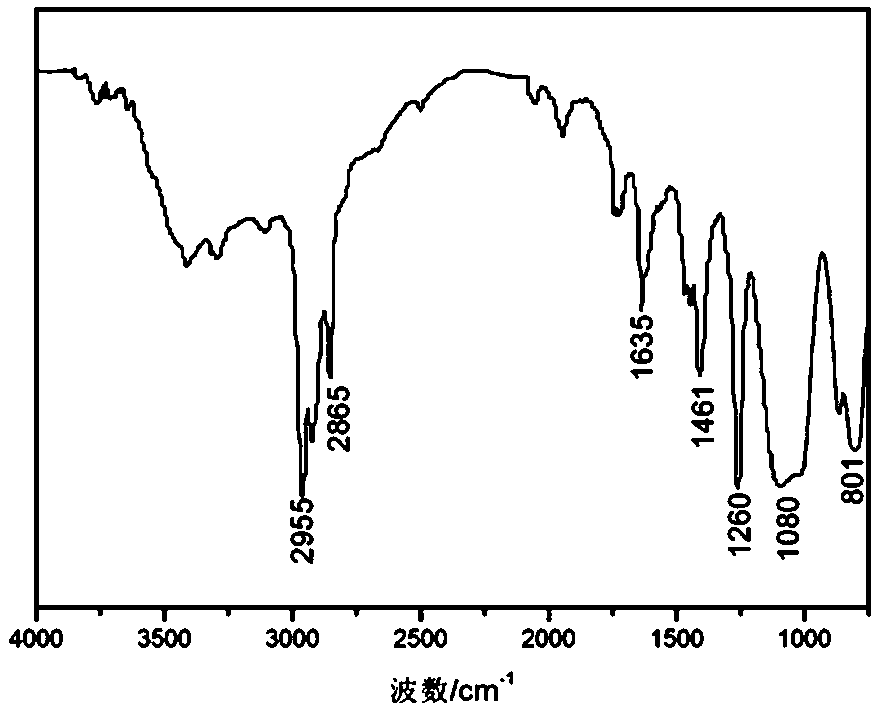

Embodiment 3

[0049] 1. Add 30g of epoxy double head and 45g of octadecylamine into the first reaction vessel with a stirrer and condensing reflux device, turn on the condensing device and agitator, and start heating after 10 minutes of nitrogen gas, and the temperature rises The intermediate product I was obtained after reacting for 4.5 hours at 80°C.

[0050] 2. Add 30g of intermediate product I, 12g of γ-piperazinylpropylmethyldimethoxysilane and 300g of octamethylcyclotetrasiloxane into the second reaction vessel equipped with a stirrer, and turn on the stirrer. The temperature was raised to 75°C, 0.32g of tetramethylammonium hydroxide was added, and the temperature was continued to rise to 100°C. After 6 hours of reaction, the intermediate product II was obtained.

[0051] 3. Add 315g of intermediate product II, 6.9g of triethylamine and 139.6g of acetone into the third reaction vessel equipped with a stirrer and a dripping device, add 34.2g of octadecanoyl chloride into the dripping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com