Method for surface coating modified spinel phase positive electrode material

A positive electrode material and surface coating technology, which is applied in the field of surface coated modified spinel phase positive electrode materials, can solve problems such as crystal structure differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Add 0.03mol of citric acid and 0.02mol of glucose into 50ml of deionized water, after the citric acid and glucose are dissolved, add 0.01mol of magnesium nitrate and 0.02mol of aluminum nitrate, stir and dissolve to form Sol A;

[0083] Add 140.84g of lithium manganate cathode material to sol A, stir magnetically at room temperature for 30min at a speed of 400r / min to form sol B;

[0084] The sol was evaporated to dryness with magnetic stirring at a constant temperature of 90°C to obtain a xerogel;

[0085] Grinding the above-mentioned xerogel to obtain a grinding product, and then heat-treating the grinding product at 850° C. for 3 hours under an air atmosphere, and then cooling in a furnace to finally obtain a surface-modified lithium manganate.

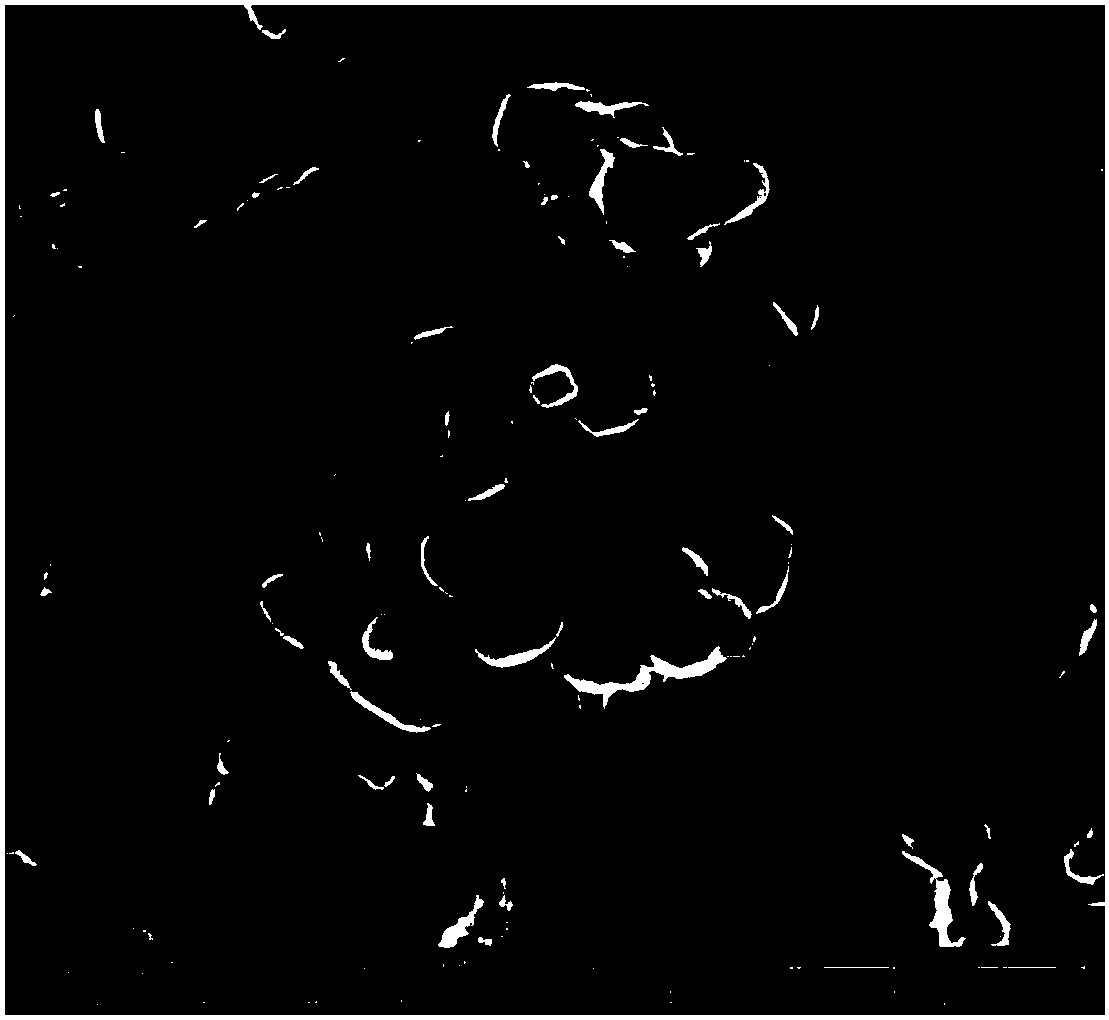

[0086] Scanning electron microscopy was carried out on it, and the results were as follows: figure 1 shown by figure 1 It can be seen that the particles of lithium manganate modified by surface coating have good particle d...

Embodiment 2

[0089] Add 0.03 mol of citric acid and 0.02 mol of glucose to 50 ml of deionized water, after the citric acid and glucose are dissolved, add 0.01 mol of magnesium nitrate and 0.02 mol of aluminum nitrate, stir and dissolve to form sol A;

[0090] Add 140.84g of lithium nickel manganese oxide positive electrode material to sol A, stir magnetically at room temperature for 30min at a speed of 400r / min to form sol B;

[0091] The sol was evaporated to dryness with magnetic stirring at a constant temperature of 90°C to obtain a xerogel;

[0092] Grinding the above xerogel to obtain a grinding product, then heat-treating the grinding product at 900° C. for 2 hours in an air atmosphere, and then cooling in a furnace to finally obtain a surface-modified lithium nickel manganese oxide.

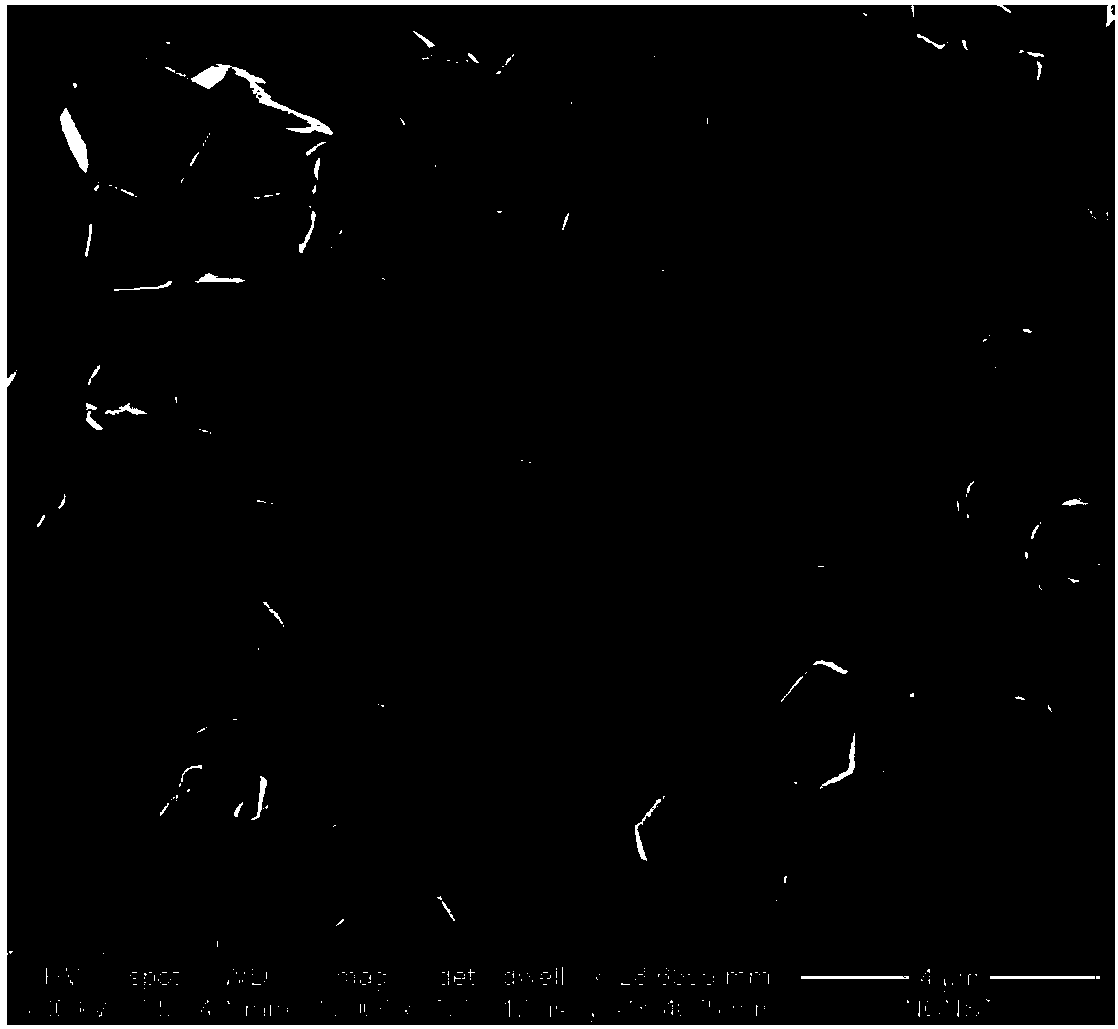

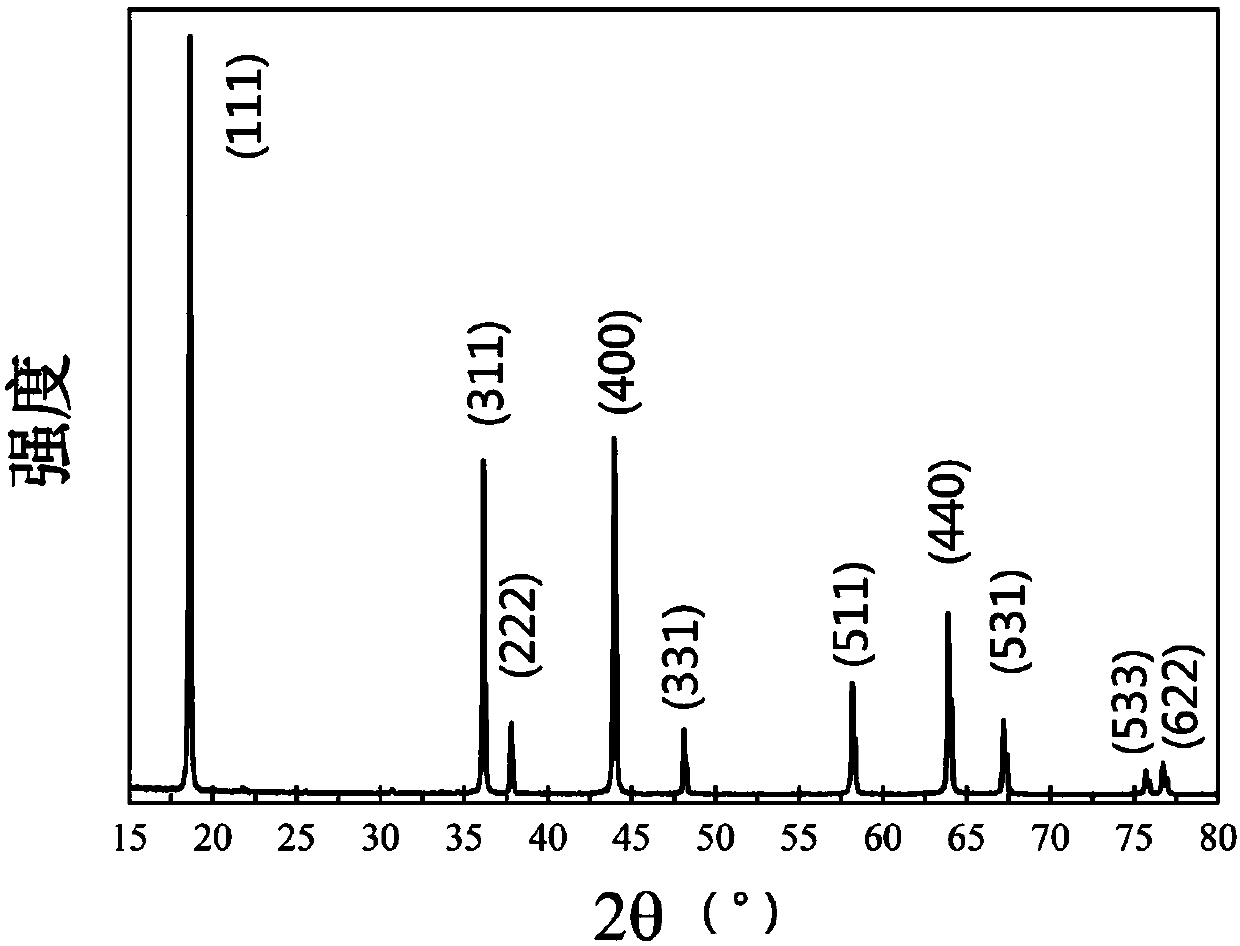

[0093] Scanning electron microscopy was carried out on it, and the results were as follows: figure 2 shown by figure 2 It can be seen that the particles of lithium nickel manganese oxide modified b...

Embodiment 3

[0096] Add 0.03 mol of citric acid and 0.02 mol of glucose to 50 ml of deionized water, after the citric acid and glucose are dissolved, add 0.01 mol of magnesium nitrate and 0.02 mol of aluminum nitrate, stir and dissolve to form sol A;

[0097] Add 211.26g of lithium nickel manganese oxide positive electrode material to sol A, and magnetically stir at room temperature for 30min at a speed of 400r / min to form sol B;

[0098] The sol was evaporated to dryness with magnetic stirring at a constant temperature of 100°C to obtain a xerogel;

[0099] Grinding the above xerogel to obtain a grinding product, then heat-treating the grinding product at 900° C. for 2 hours in an air atmosphere, and then cooling in a furnace to finally obtain a surface-modified lithium nickel manganese oxide. Its scanning electron microscope picture and XRD collection of illustrative plates are similar to embodiment 2 result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com