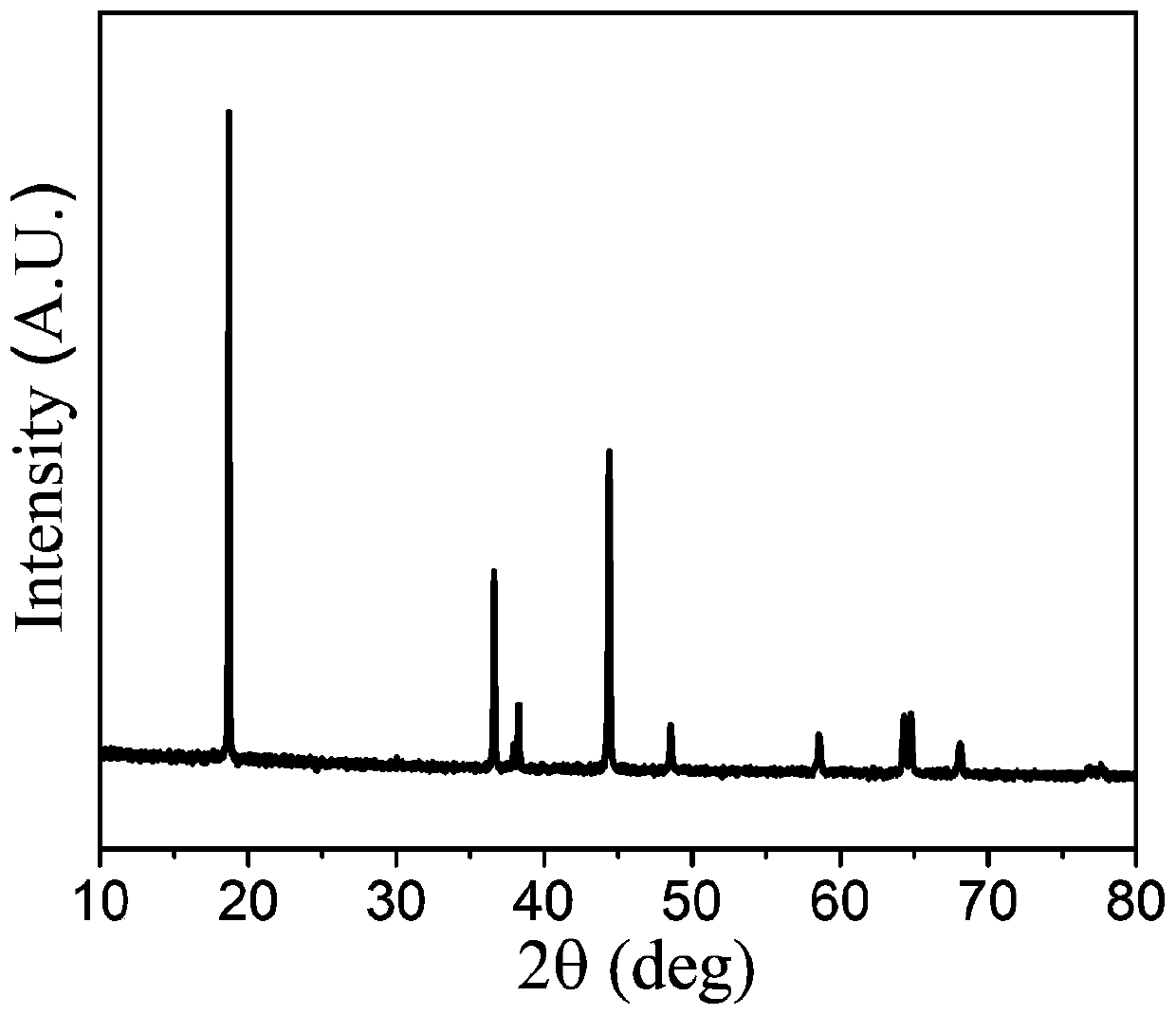

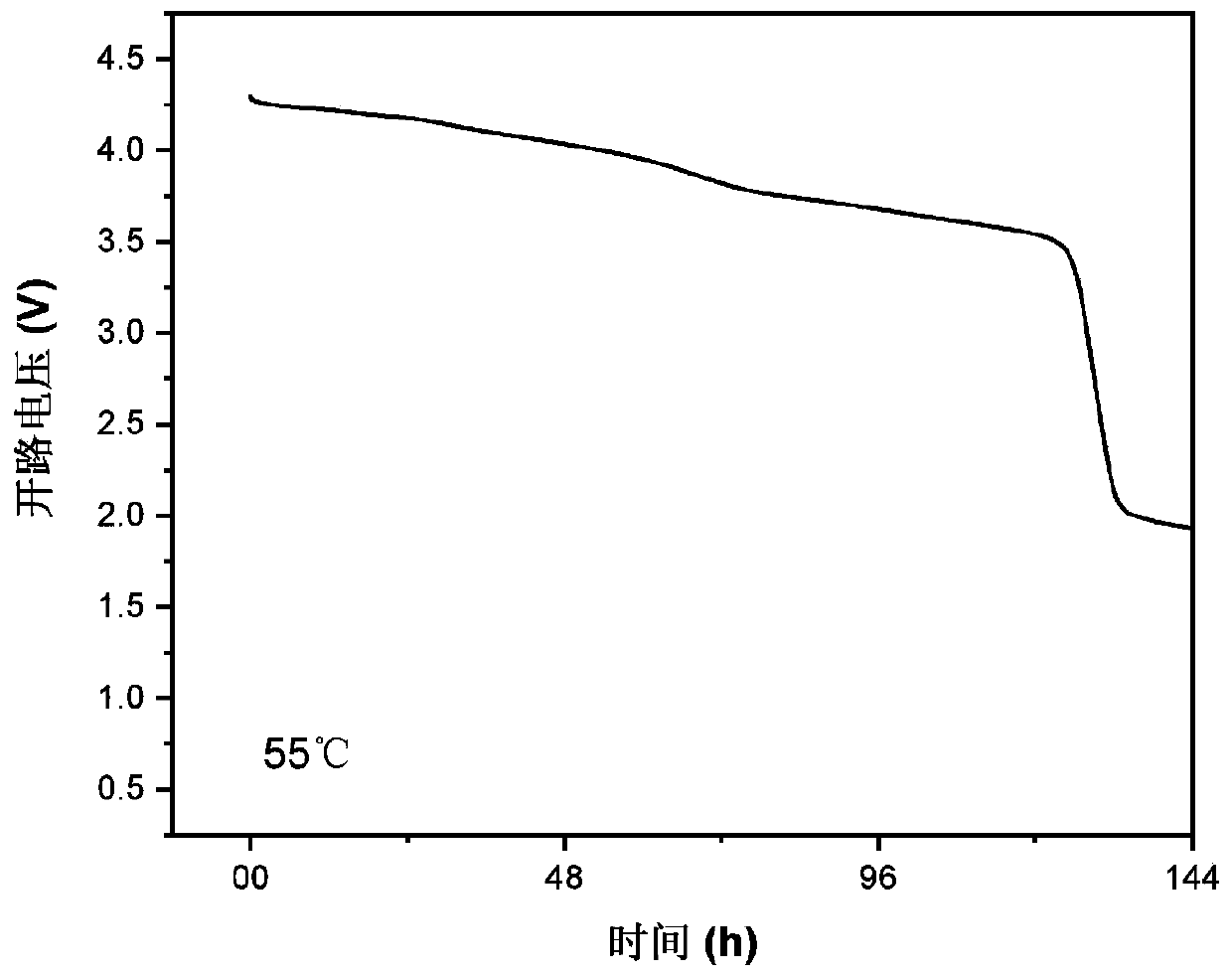

High-specific-capacity lithium nickel-cobalt-manganese cathode material and a preparation method thereof

A technology of nickel cobalt lithium manganate and cathode material, which is applied in the field of high specific capacity nickel cobalt lithium manganate cathode material and its preparation, can solve the problems of secondary particle cracks, cation mixing, poor thermal stability, etc., and achieves crack suppression. , low cost, and the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Configure metal sulfate solution, nickel sulfate concentration is 1.6mol / L, cobalt sulfate concentration is 0.2mol / L, manganese sulfate concentration is 0.2mol / L, aluminum sulfate concentration is 0.002mol / L;

[0039] Step 2: Prepare 20% NaOH solution and 10% ammonia solution;

[0040] Step 3: Add sodium hydroxide solution and ammonia solution to the metal solution, adjust the pH to 11, so that NH 4 The concentration of OH and metal ions are equal;

[0041] Step 4: Stir the mixed solution prepared in step 3 at 45°C and 600 rpm for 8 hours, wash after the reaction, filter with suction and dry at 60°C with air as the drying atmosphere to obtain a precursor of nickel-cobalt-manganese hydroxide doped with aluminum body;

[0042] Step 5: Mix the precursor obtained in Step 4 with lithium hydroxide, diboron trioxide, and silicon dioxide by ball milling, and the molar ratio of each component is 1:1.05:0.02:0.01;

[0043] Step 6: The mixture obtained in step 5 is heated to 480°C ...

Embodiment 2

[0054] Step 1: Configure metal sulfate solution, nickel sulfate concentration is 1.6mol / L, cobalt sulfate concentration is 0.2mol / L, manganese sulfate concentration is 0.2mol / L, aluminum sulfate concentration is 0.04mol / L;

[0055] Step 2: Prepare 10% NaOH solution and 5% ammonia solution;

[0056] Step 3: Add sodium hydroxide solution and ammonia solution to the metal solution to adjust the pH to 9;

[0057] Step 4: Stir the mixed solution prepared in step 3 at 1000 rpm at 40°C for 6 hours, wash, filter and dry after the reaction to obtain a nickel cobalt manganese hydroxide precursor containing doped aluminum;

[0058] Step 5: Mix the precursor obtained in Step 4 with lithium hydroxide, diboron trioxide, and silicon dioxide by ball milling, and the molar ratio of each component is 1:1.05:0.001:0.02;

[0059] Step 6: Heat the mixture obtained in step 5 to 520°C in an air or oxygen atmosphere, keep it for 8 hours, then heat to 900°C, keep it for 10 hours, at a temperature increase rate ...

Embodiment 3

[0061] Step 1: Configure metal sulfate solution, nickel sulfate concentration is 1.2mol / L, cobalt sulfate concentration is 0.4mol / L, manganese sulfate concentration is 0.4mol / L, aluminum sulfate concentration is 0.02mol / L;

[0062] Step 2: Prepare 15% NaOH solution and 8% ammonia solution;

[0063] Step 3: Add sodium hydroxide solution and ammonia solution to the metal solution to adjust the pH to 10;

[0064] Step 4: Stir the mixed solution prepared in step 3 at 40° C. and 800 rpm for 10 hours, wash, filter and dry after the reaction to obtain a nickel cobalt manganese hydroxide precursor containing doped aluminum;

[0065] Step 5: Mix the precursor obtained in step 4 with lithium hydroxide, diboron trioxide, and silica ball milling thoroughly, and the molar ratio of each component is 1:1.05:0.01:0.015;

[0066] Step 6: The mixture obtained in step 5 is heated to 500°C under an air or oxygen atmosphere, kept for 7 hours, and then heated to 850°C, kept for 15 hours, at a temperature inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com