Method for producing natural fagopyrum tararicum leaf bud tea

A technology of tartary buckwheat leaf and bud tea, which is applied in the processing field of natural tartary buckwheat leaf bud tea, which can solve the problems that the quality of tea products cannot meet the unified standard, the quality of tea products is not good, and the tea fragrance cannot be fully released, etc., and achieve the appearance quality and nutrition Excellent value, excellent appearance, and the effect of maintaining the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

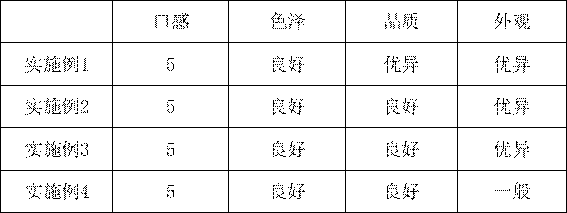

Examples

Embodiment 1

[0035] The processing method of tartary buckwheat bud tea comprises the steps:

[0036] 1 is picking: pick tartary buckwheat that has been planted in the field for 50-55 days, and pick 1-3 fresh leaves counting from top to bottom and the widest part of the leaf is not more than 4cm on its raw branches or side branches, wherein the fresh leaves It is required to be complete, bright green and even in color;

[0037] 2. Screening: according to the size of tartary buckwheat leaf buds, sieve them into different grades, and remove damage, disease and poor color leaf buds in each grade of tartary buckwheat leaf buds;

[0038]3. Thickening: adopt the method of natural withering, evenly spread the fresh tartary buckwheat leaves on the bamboo airing bed, dry them in a ventilated and cool place until wilting, collect the baskets, spread the thickness of 5-8cm, and control the temperature at 20-22 ℃, the relative humidity is 60-65%, and the wilting time is 15-18 hours. During the wilting...

Embodiment 2

[0050] The processing method of tartary buckwheat bud tea comprises the steps:

[0051] 1. Picking: Select tartary buckwheat that has been planted in the field for 35-49 days, and pick 1-3 fresh leaves counting from top to bottom on its raw branches or side branches, and the widest part of the leaves is not greater than 4cm;

[0052] 2. Screening: according to the size of tartary buckwheat leaf buds, sieve them into different grades, and remove damage, disease and poor color leaf buds in each grade of tartary buckwheat leaf buds;

[0053] 3. Thickening: adopt the method of natural withering, evenly spread the fresh tartary buckwheat leaves on the bamboo airing bed, dry them in a ventilated and cool place until wilting, collect the baskets, spread the thickness of 5-8cm, and control the temperature at 20-22 ℃, relative humidity 60-65%, withering time is 15-18 hours;

[0054] 4. Finishing: Add the withered tartary buckwheat leaves into the finishing machine, control the tempera...

Embodiment 3

[0065] The processing method of tartary buckwheat bud tea comprises the steps:

[0066] 1. Picking: Select tartary buckwheat that has been planted in the field for 56-65 days, and pick 1-3 fresh leaves counting from top to bottom on its raw branches or side branches, and the widest part of the leaves is not greater than 4cm;

[0067] 2. Screening: according to the size of tartary buckwheat leaf buds, sieve them into different grades, and remove damage, disease and poor color leaf buds in each grade of tartary buckwheat leaf buds;

[0068] 3. Thickening: adopt the method of natural withering, evenly spread the fresh tartary buckwheat leaves on the bamboo airing bed, dry them in a ventilated and cool place until wilting, collect the baskets, spread the thickness of 5-8cm, and control the temperature at 20-22 ℃, relative humidity 60-65%, withering time is 15-18 hours;

[0069] 4. Finishing: Add the withered tartary buckwheat leaves into the finishing machine, control the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com