Waste heat recycling system for aquarium and working method thereof

A waste heat recovery and marine technology, applied in fluid heaters, clean heat transfer devices, lighting and heating equipment, etc., can solve the problems of increasing the operating cost of the aquarium, consuming large energy, and high labor costs, so as to reduce the frequency of water changes, The effect of reducing energy waste and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

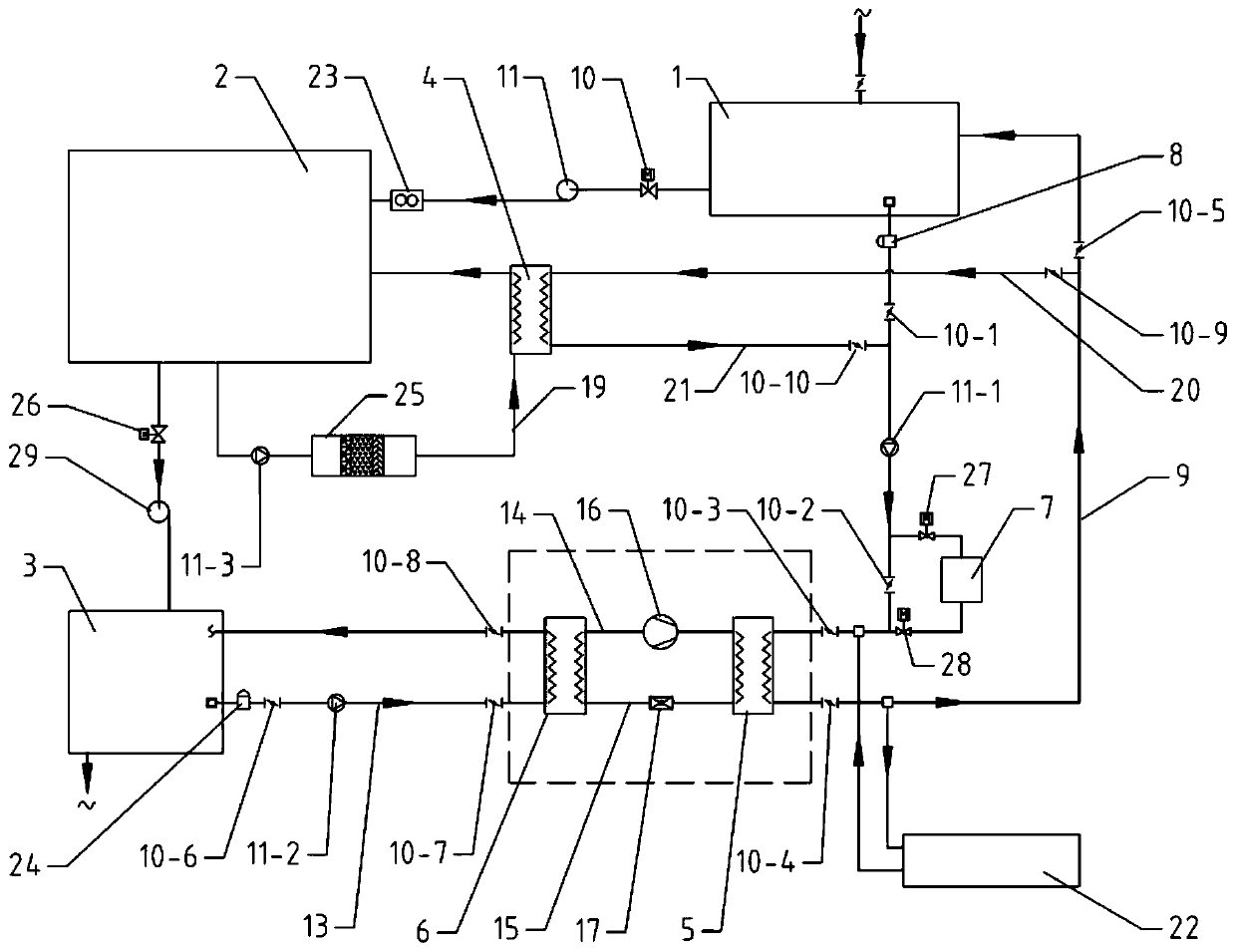

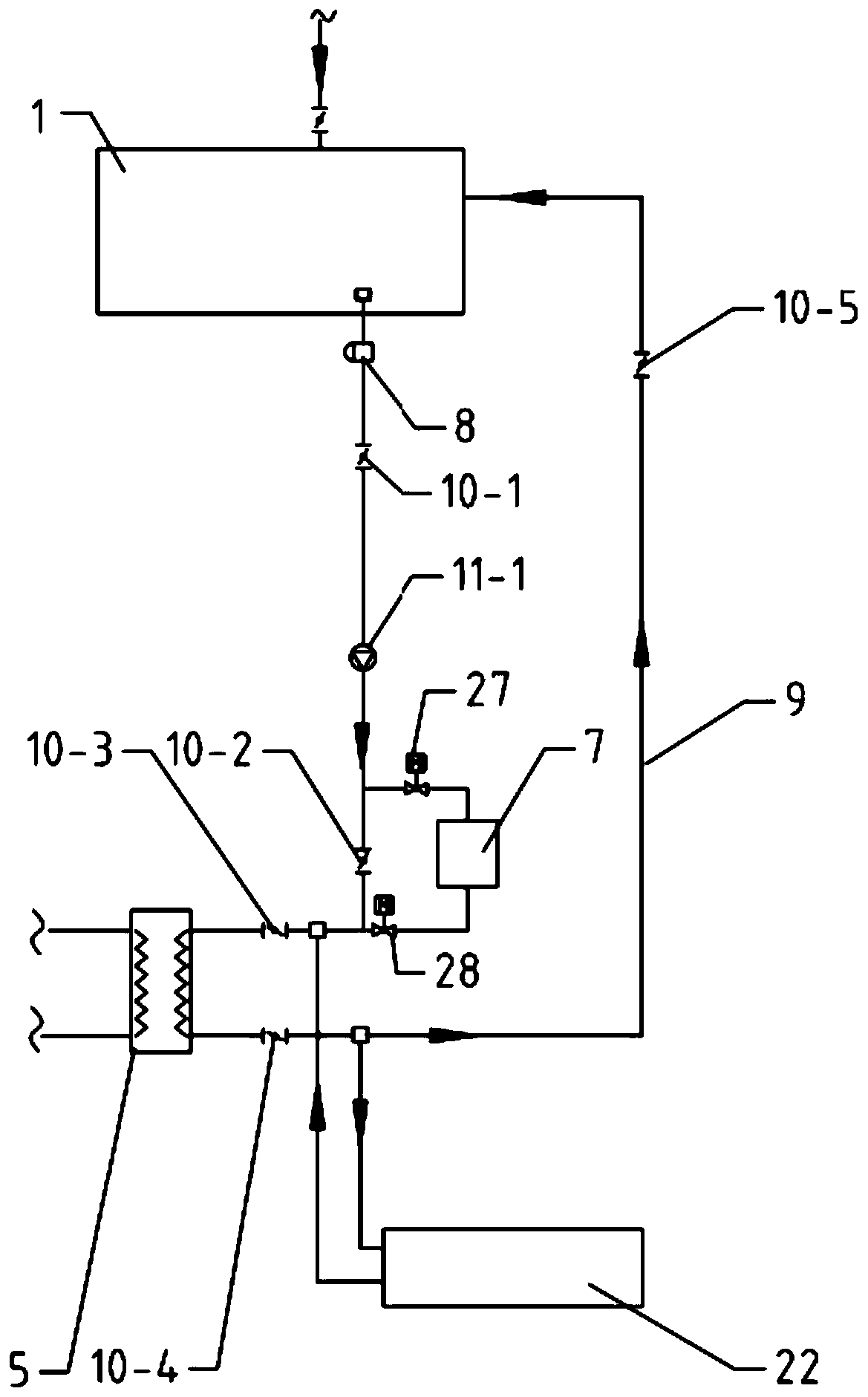

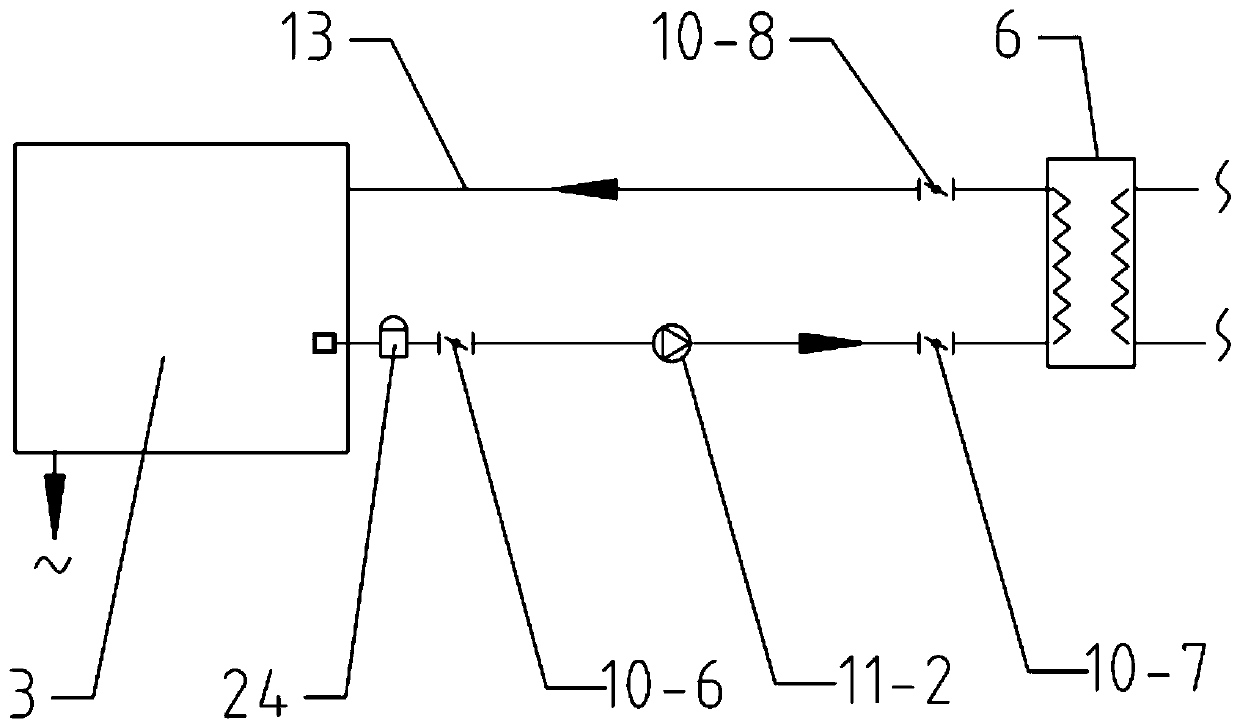

[0039] like Figure 1-4 As shown, a waste heat recovery and utilization system for an aquarium includes a seawater storage tank 1, a display tank 2, a sewage tank 3, a condenser 5, an evaporator 6, and a heating device 7. The seawater storage tank 1 and The display pool 2 is connected through a water pipe equipped with a first electromagnetic valve 10 and a first centrifugal pump 11, and the display pool 2 and the sewage pool 3 are connected through a water pipe equipped with a second centrifugal pump 29 and a second electromagnetic valve 26. like figure 2 As shown, the seawater storage tank 1 is connected with a first circulation branch 9, and the first circulation branch 9 is provided with a first pneumatic butterfly valve 10-1, a first water pump 11-1, and a second pneumatic butterfly valve in sequence. 10-2. The third pneumatic butterfly valve 10-3, the condenser 5, the fourth pneumatic butterfly valve 10-4, and the fifth pneumatic butterfly valve 10-5. Both the water in...

Embodiment 2

[0051] On the basis of Embodiment 1, the present invention also provides a working method for the waste heat recovery and utilization system of the aquarium, which includes the following steps:

[0052] S1: When the seawater in the display pool 2 needs to be replaced, manually turn on the second centrifugal pump 29 and the second solenoid valve 26 to pump the warm seawater in the display pool 2 into the sewage pool 3 for standby; Enter the seawater storage tank 1 for subsequent use.

[0053] S2: start the control system, when the second temperature detection device detects that the seawater temperature in the seawater storage tank 1 is lower than the set value, the PLC controller sends a driving signal to control the execution of the following work: first, open the first circulation branch 9 The first pneumatic butterfly valve 10-1, the second pneumatic butterfly valve 10-2, the third pneumatic butterfly valve 10-3, the fourth pneumatic butterfly valve 10-4, the fifth pneumati...

Embodiment 3

[0059] like Image 6 As shown, on the basis of embodiment 1, remove the filter screen of the rubber ball cleaning device 22, the water inlet filter screen of the first circulation branch 9 and the first sand tank filter 8, the water inlet of the second circulation branch 13 and the first The second sand tank filter 24 connects the water inlet and the water return port of the first circulation branch 9 through the heat dissipation coil 12 to form a closed circuit, the medium in the pipe is heat transfer oil, and the second circulation branch 13 The water inlet and the water return port are connected through the heat-absorbing coil 18 to form a closed circuit, and the medium in the pipe is heat-conducting oil. Wherein, the heat-resisting coil 12 and the heat-absorbing coil 18 are made of heat-resistant polyethylene, and in other embodiments, the material of the heat-dissipating coil 12 and the heat-absorbing coil 18 can also be made of triplicated polypropylene.

[0060] Absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com