Late-egg-laying-stage compound premixed feed for improving egg shell quality of laying hens

A technology of premixed feed and laying hens, which is applied in animal feed, animal feed, application, etc., can solve the problems of weakened disease resistance, lighter eggshell color, and lower egg production performance, so as to reduce harm and improve eggshell color. Deep, improve the effect of digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

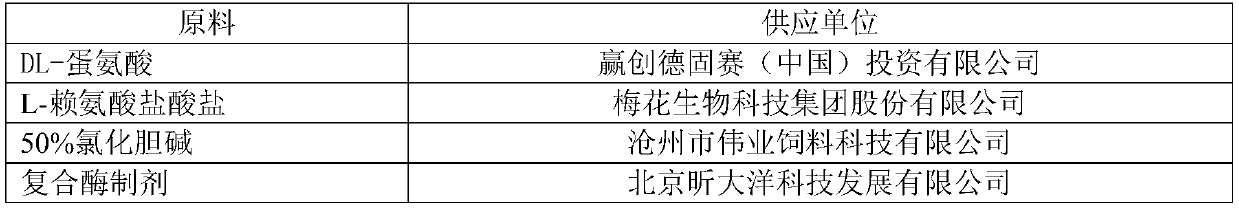

[0085] The formula of the compound premixed feed for laying hens specifically includes the following components by mass: 10 parts of compound vitamins; 25 parts of compound trace elements; 20 parts of choline chloride (50% by mass); 40 parts of DL-methionine 14 parts of L-lysine hydrochloride; 3.5 parts of phytase; 5 parts of compound enzyme preparation; 3.5 parts of probiotics; 100 parts of sodium chloride; 300 parts of calcium hydrogen phosphate; 100 parts of hemoglobin powder; 110 parts of montmorillonite; 2 parts of ethoxyquinoline.

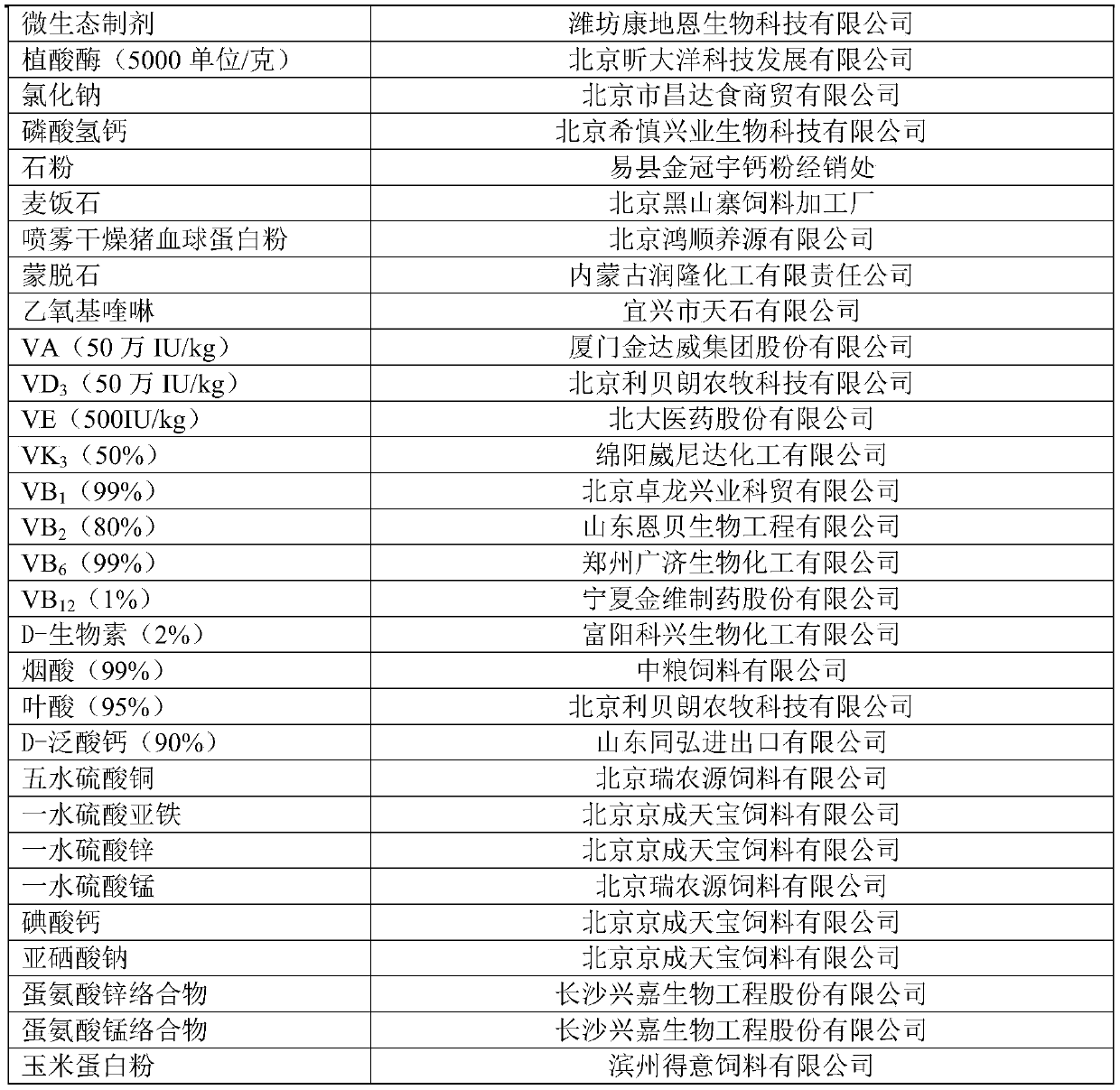

[0086] Among them, every kilogram of multivitamins includes the following components: vitamin A 31-34 million IU, vitamin D 3 16-12.78 million IU, vitamin E 45-55 thousand IU, vitamin K 3 6.18~7.5g, Vitamin B 1 6.1~8.8g, Vitamin B 2 20.09~34.55g, Vitamin B 6 11.45~16.75g, Vitamin B 12 6.45-8.35g, niacin 83.7-102.3g, D-calcium pantothenate 32.31-39.49g, folic acid 2.52-4.28g, D-biotin 33.5-42.8g, and the balance is carrier corn gluten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com