Preparation method of titanium carbide/zinc indium sulfide composite visible light photocatalyst

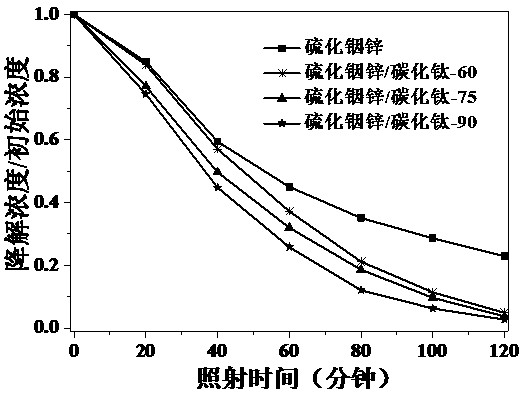

A technology of indium zinc sulfide and titanium carbide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low migration ability, low photocatalytic degradation activity of pure indium zinc sulfide, and photoexcited charge Carrier separation efficiency is poor and other problems, to achieve the effect of easy preparation conditions, easy operation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

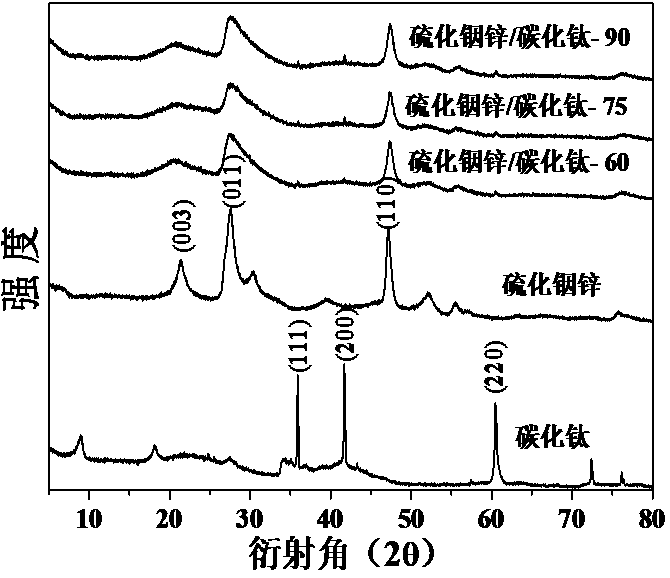

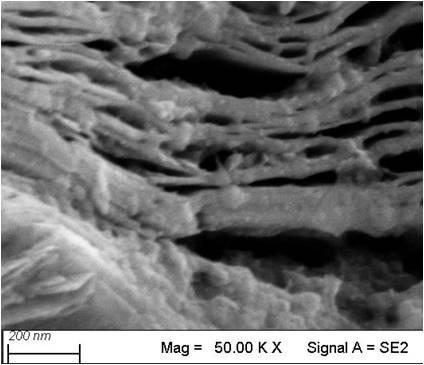

[0018] (1) Preparation of titanium carbide: 1 g of titanium aluminum carbide was added to 30 mL of 40% hydrofluoric acid, and etched in an oil bath at 50°C for 24 h to obtain an accordion-shaped aluminum carbide (Ti 3 C 2 ).

[0019] (2) Preparation of titanium carbide / indium zinc sulfide composite visible light catalyst: firstly, mix 10 mmol sulfur powder with 10 mL oleic acid, put in an oil bath at 115 °C for 20 min, then raise the temperature to 150 °C, and continue the oil bath for 10-20 min, Prepare 1mol / L OA-S solution. Then, add 1 mmol of zinc acetate, 2 mmol of indium trichloride, 10 mL of oleylamine and 4 g of tri-n-zinc-based phosphine oxide into a three-neck round bottom flask, and heat up to 200 °C in an oil bath at 110 °C for 20 min under nitrogen protection. ℃, 4 mL of OA-S solution was quickly injected after 5 min, 20-30 mL of ethanol was injected immediately after 30 min, cooled to room temperature, and centrifuged at 9000 r / min for 2 min to obtain indium zin...

Embodiment 2

[0021] (1) Preparation of titanium carbide: 1 g of titanium aluminum carbide was added to 30 mL of 40% hydrofluoric acid, and etched in an oil bath at 50°C for 24 h to obtain an accordion-shaped aluminum carbide (Ti 3 C 2 ).

[0022] (2) Preparation of titanium carbide / indium zinc sulfide composite visible light catalyst: firstly, mix 10 mmol sulfur powder with 10 mL oleic acid, put in an oil bath at 115 °C for 20 min, then raise the temperature to 150 °C, and continue the oil bath for 10-20 min, Prepare 1mol / L OA-S solution. Then, add 1 mmol of zinc acetate, 2 mmol of indium trichloride, 10 mL of oleylamine and 4 g of tri-n-zinc-based phosphine oxide into a three-neck round bottom flask, and heat up to 200 °C in an oil bath at 110 °C for 20 min under nitrogen protection. ℃, 4 mL of OA-S solution was quickly injected after 5 min, 20-30 mL of ethanol was injected immediately after 30 min, cooled to room temperature, and centrifuged at 9000 r / min for 2 min to obtain indium zin...

Embodiment 3

[0024] (1) Preparation of titanium carbide: 1 g of titanium aluminum carbide was added to 30 mL of 40% hydrofluoric acid, and etched in an oil bath at 50°C for 24 h to obtain an accordion-shaped aluminum carbide (Ti 3 C 2 ).

[0025] (2) Preparation of titanium carbide / indium zinc sulfide composite visible light catalyst: firstly, mix 10 mmol sulfur powder with 10 mL oleic acid, put in an oil bath at 115 °C for 20 min, then raise the temperature to 150 °C, and continue the oil bath for 10-20 min, Prepare 1mol / L OA-S solution. Then, add 1 mmol of zinc acetate, 2 mmol of indium trichloride, 10 mL of oleylamine and 4 g of tri-n-zinc-based phosphine oxide into a three-neck round bottom flask, and heat up to 200 °C in an oil bath at 110 °C for 20 min under nitrogen protection. ℃, 4 mL of OA-S solution was quickly injected after 5 min, 20-30 mL of ethanol was injected immediately after 30 min, cooled to room temperature, and centrifuged at 9000 r / min for 2 min to obtain indium zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com