Preparation method of high-performance polyimide and application of the high-performance polyimide in lithium battery electrode

A polyimide, high-performance technology, applied in the field of organic synthesis, can solve the problems of unsatisfactory mechanical properties and chemical stability, high crystallinity of PVDF, unsmooth use process, etc., and achieve excellent erasability and electrolysis resistance Good liquid and bending resistance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

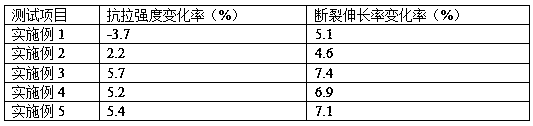

Examples

Embodiment 1

[0020] A kind of high-performance polyimide preparation method proposed by the present invention and its application in lithium battery electrode comprise the following steps:

[0021] S1. Weigh 3,3'4,4-diphenylmethyl ether tetra-acid dianhydride, put it in a reaction flask, and pass nitrogen gas into the reaction flask for 20 minutes, then add N,N-dimethylacetamide, Stir at a speed of 200r / min until the 3,3'4,4-diphenylmethyl ether tetra-acid dianhydride is completely dissolved, if the 3,3'4,4-diphenyl methyl ether tetra-acid dianhydride is not completely dissolved within 5min , then increase the system temperature to 30-35°C or increase the stirring speed to 280r / min and continue to stir until the aromatic dianhydride 3,3'4,4-diphenylmethyl ether tetraacid dianhydride is completely dissolved to obtain the reaction solution I;

[0022] S2. Adjust the temperature of the reaction solution I to 38°C, and add 1,10-diaminodecane to the reaction solution I at a rate of 2g / min, and ...

Embodiment 2

[0025] A kind of high-performance polyimide preparation method proposed by the present invention and its application in lithium battery electrode comprise the following steps:

[0026] S1. Weigh 3,3',4,4'-biphenyltetracarboxylic dianhydride and place it in the reaction flask, and then inject nitrogen gas into the reaction flask for 0min, then add N-methylpyrrolidone at 150r / min Stir at a high speed until the aromatic dianhydride 3,3',4,4'-biphenyltetracarboxylic dianhydride and pyromellitic anhydride are completely dissolved, if 3,3',4,4'-biphenyltetracarboxylic acid If the dianhydride is not completely dissolved within 5 minutes, raise the temperature of the system to 30-35°C or increase the stirring speed to 300r / min and continue stirring until the 3,3',4,4'-biphenyltetracarboxylic dianhydride is completely dissolved , to obtain reaction solution I;

[0027] S2. Adjust the temperature of the reaction solution I to 40°C, and add 1,10-diaminodecane to the reaction solution I ...

Embodiment 3

[0030] A kind of high-performance polyimide preparation method proposed by the present invention and its application in lithium battery electrode comprise the following steps:

[0031] S1. Weigh 3,3'4,4-diphenylmethyl ether tetra-acid dianhydride, place it in a reaction flask, and pass nitrogen gas into the reaction flask for 40 minutes, then add N,N-dimethylacetamide, Stir at a speed of 100r / min until the 3,3'4,4-diphenylmethyl ether tetra-acid dianhydride is dissolved. If the 3,3'4,4-diphenyl methyl ether tetra-acid dianhydride is not completely dissolved within 5 minutes, Then raise the temperature of the system to 35°C or increase the stirring speed to 300r / min and continue to stir until the 3,3'4,4-diphenylmethyl ether tetra-acid dianhydride is completely dissolved to obtain the reaction solution I;

[0032] S2. Adjust the temperature of the reaction solution I to 38°C, and add p-phenylenediamine to the reaction solution I at a rate of 2 g / min. After the addition of p-phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com