Method for coarse refining of lignin in straws by catalyzing ethanol with oxygen and application of method

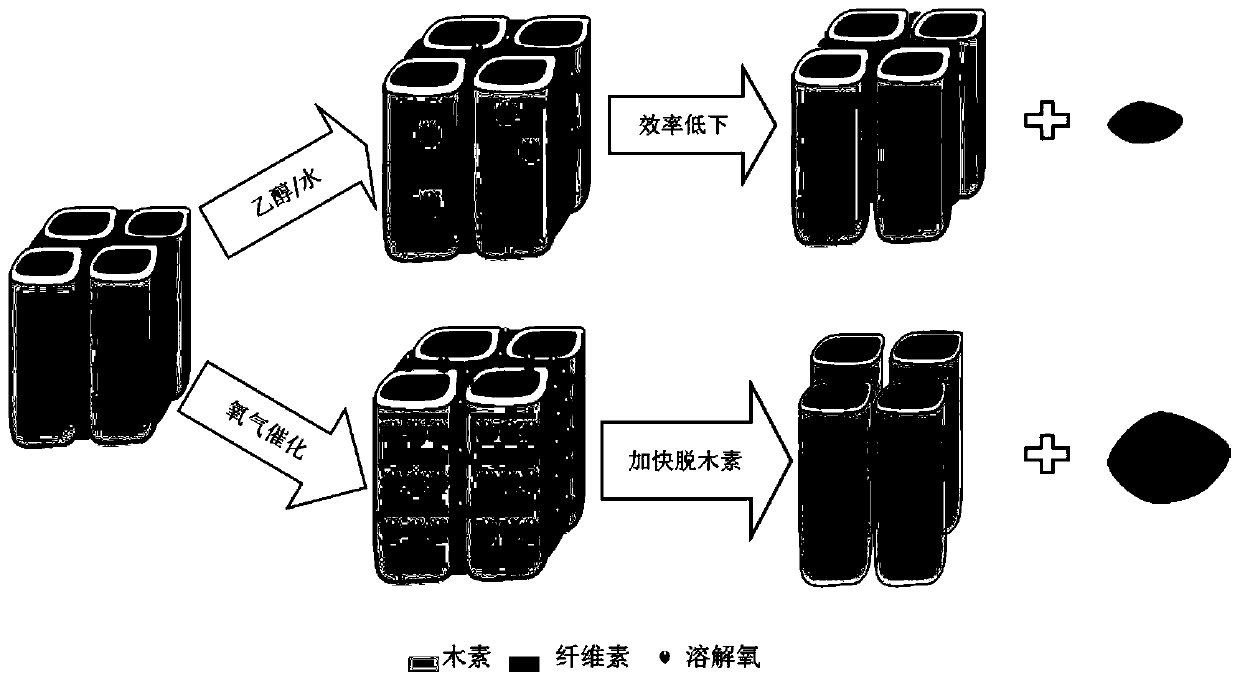

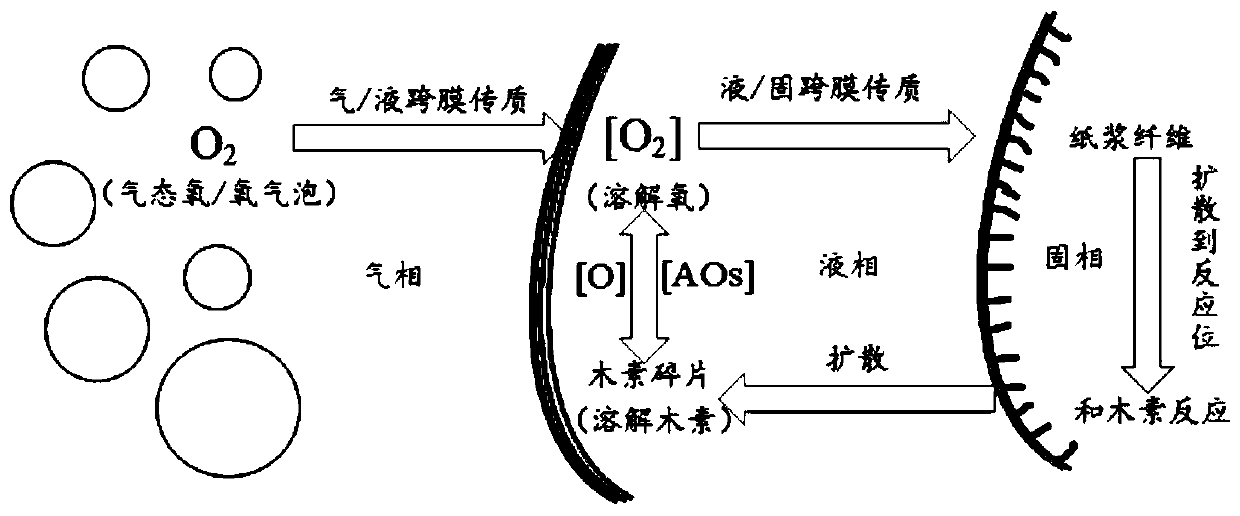

A technology of straw and ethanol, which is applied in the fields of pulping with organic solvents, textile and papermaking, and fiber raw material treatment, can solve the problems of reducing lignin removal rate, excessive degradation of carbohydrates, and increased degree of cellulose degradation, etc., to achieve Improve process operation safety, promote penetration and diffusion, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] S1: Crushing the straw. Shorten the wheat straw to about 5 cm, put it into a pulverizer, run it for 30 seconds to obtain powdery straw, and dry it at 105°C for 4 hours to obtain dry powdery straw.

[0038] S2: Accurately weigh 10 g of absolute dry powdery straw, and place it in a 250 mL reaction kettle. Prepare an aqueous ethanol solution with a mass concentration of 70% with distilled water, and add it to the reaction kettle according to the ratio of material to liquid 1:10.

[0039] S3: Start the stirring rotor to stir, seal the reaction kettle, open the gas inlet and outlet valves, pass oxygen into the reaction kettle for 5 minutes, judge according to experience and common sense that the air above the material is completely replaced by oxygen, and then close the gas outlet valve.

[0040] S4: Start the reactor, heat it to 70°C, and keep it warm for 2 hours to react. During the reaction, keep oxygen flowing. When the pressure in the reactor reaches about 0.8-1.3Mpa, ...

Embodiment 2

[0047] S1: Crushing the straw. Shorten the wheat straw to about 5 cm, put it into a pulverizer, run it for 30 seconds to obtain powdery straw, and dry it at 105°C for 4 hours to obtain dry powdery straw.

[0048] S2: Accurately weigh 10 g of absolute dry powdery straw, and place it in a 250 mL reaction kettle. Prepare an aqueous ethanol solution with a mass concentration of 80% with distilled water, and add it to the reaction kettle according to the ratio of material to liquid 1:20.

[0049] S3: Start the stirring rotor to stir, seal the reaction kettle, open the gas inlet and outlet valves, pass oxygen into the reaction kettle for 5 minutes, judge according to experience and common sense that the air above the material is completely replaced by oxygen, and then close the gas outlet valve.

[0050] S4: Start the reactor, heat it to 80°C, and keep it warm for 3 hours to react. During the reaction, keep oxygen flowing. When the pressure in the reactor reaches about 0.8-1.3Mpa, ...

Embodiment 3

[0057] S1: Crushing the straw. Shorten the wheat straw to about 5 cm, put it into a pulverizer, run it for 30 seconds to obtain powdery straw, and dry it at 105°C for 4 hours to obtain dry powdery straw.

[0058] S2: Accurately weigh 5 g of dry powdered straw and place it in a 250 mL reaction kettle. Prepare an aqueous ethanol solution with a mass concentration of 80% with distilled water, and add it to the reaction kettle according to the ratio of material to liquid 1:30.

[0059] S3: Start the stirring rotor to stir, seal the reaction kettle, open the gas inlet and outlet valves, pass oxygen into the reaction kettle for 5 minutes, judge according to experience and common sense that the air above the material is completely replaced by oxygen, and then close the gas outlet valve.

[0060] S4: Start the reactor, heat it to 90°C, and keep it warm for 2 hours to react. During the reaction, keep oxygen flowing. When the pressure in the reactor reaches about 0.8-1.3Mpa, the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com