A method for preparing hydrangea ergosterol by electric field-semi-bionic technology

A technology of ergosterol and hydrangea, applied in the field of hydrangea, can solve the problems of poor adaptability of extracts, large organic solvents, excessive heavy metal content, etc., and achieve the goal of improving semi-bionic extraction rate, enhancing stability, and preventing oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

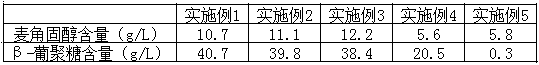

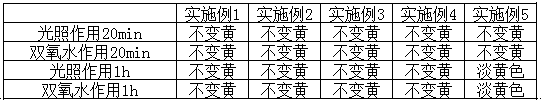

Embodiment 1

[0027] Take 100g of hydrangea fruiting body, grind and pulverize, pass through a 200-mesh sieve, put the obtained hydrangea powder into a high-voltage pulse device, add 2L of NaOH solution, adjust the pH of the solution to 9, heat and stir at 90°C for 1 hour, and adjust the micro-electrolysis reactor Conditions, so that the electric field strength of the external electric field is 20kv / cm, and the pulse is 6 µs, so that the discharge electrode acts on the hydrangea cell membrane, and saponification reaction occurs at the same time;

[0028] Pour the mixed solution into the micro-electrolysis reactor, adjust the electrodes so that the cathode is a stainless steel electrode plate, the anode is a graphite electrode plate, and the mixed solution obtained in the above steps is electrolytically reduced, the voltage is 1.8V, and the reaction temperature is 25 ℃, the reaction time is 120min, after slowly removing the cathode electrode, centrifuge the obtained mixed solution at a centri...

Embodiment 2

[0032] Take 100g of Hydrangea fruiting bodies, grind and pulverize, pass through a 200-mesh sieve, put the obtained Hydrangea powder into a high-voltage pulse device, add 2L of KOH solution, adjust the pH value of the solution to 10, heat and stir at 90°C for 1 hour, and adjust the micro-electrolysis reactor Conditions, so that the electric field strength of the external electric field is 40kv / cm, and the pulse is 12 µs, so that the discharge electrode acts on the hydrangea cell membrane, and saponification reaction occurs at the same time;

[0033] Pour the mixed solution into a micro-electrolysis reactor, adjust the electrodes so that the cathode is a stainless steel electrode plate, and the anode is a graphite electrode plate, and the mixed solution obtained in the above steps is electrolytically reduced with a voltage of 1.8V and a reaction temperature of 25 ℃, the reaction time is 120min, after slowly removing the cathode electrode, centrifuge the obtained mixed solution a...

Embodiment 3

[0037] Take 100g of hydrangea fruiting body, grind and pulverize, pass through a 200-mesh sieve, put the obtained hydrangea powder into a high-voltage pulse device, add 2L of KOH solution, adjust the pH value of the solution to 10, heat and stir at 90°C for 1 hour, and adjust the micro-electrolysis reactor Conditions, so that the electric field strength of the external electric field is 50kv / cm, and the pulse is 10 µs, so that the discharge electrode acts on the hydrangea cell membrane, and saponification reaction occurs at the same time;

[0038] Pour the mixed solution into the micro-electrolysis reactor, adjust the electrodes so that the cathode is a stainless steel electrode plate, the anode is a graphite electrode plate, and the mixed solution obtained in the above steps is electrolytically reduced, the voltage is 1.8V, and the reaction temperature is 25 ℃, the reaction time is 120min, after slowly removing the cathode electrode, centrifuge the obtained mixed solution at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com