Fusion preparation method of vanadium-iron alloy fuse piece

A technology for vanadium ferroalloy and flakes, which is applied in the field of melting and preparation of vanadium ferroalloy flakes, can solve the problems of slow reaction and evaporation speed, many residual residues, low efficiency, etc., achieves elimination of mineral effect and particle size effect, and solves difficult oxidation of alloys. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The melting preparation method of vanadium-iron alloy melting piece of the present invention comprises the following steps:

[0027] a: Raw material preparation, weigh 3-4 parts by weight of lithium tetraborate as the main flux, 1 part by weight of lithium carbonate as the flux, 0.5-1 part by weight of oxidant and 0.1 part by weight of the sample in a filter paper bag, mix Uniform, wrapped into a ball;

[0028] b. Sample pre-oxidation, put the filter paper bag wrapped into a spherical shape in step a into a porcelain crucible with graphite powder as the bottom, place the porcelain crucible in a muffle furnace with a temperature not higher than 200°C, and heat up through the following program for melting Pre-oxidation: The heating time of the first step is not less than 20 minutes, from the initial temperature to 600°C ± 10°C; 1000℃~1100℃±10℃ holding time is not less than 15min; in the third step, the cooling time is not less than 20min, and the porcelain crucible is ta...

Embodiment 1

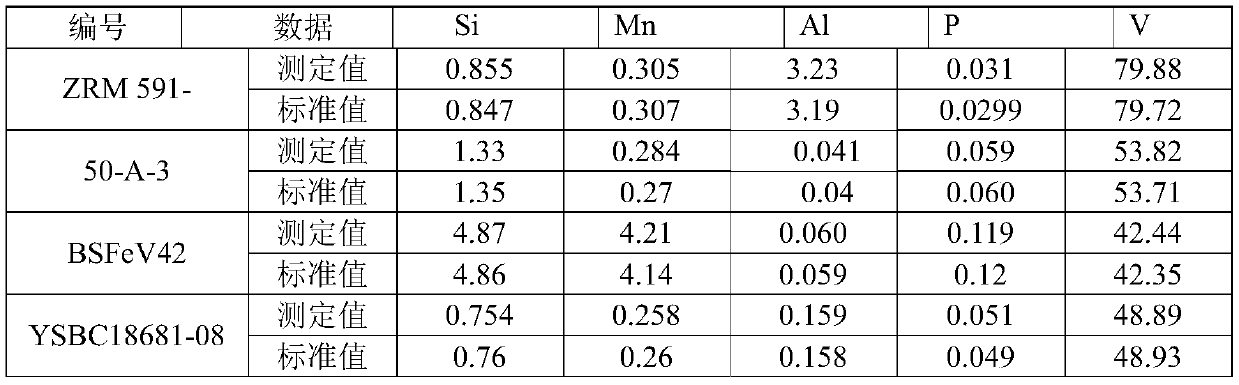

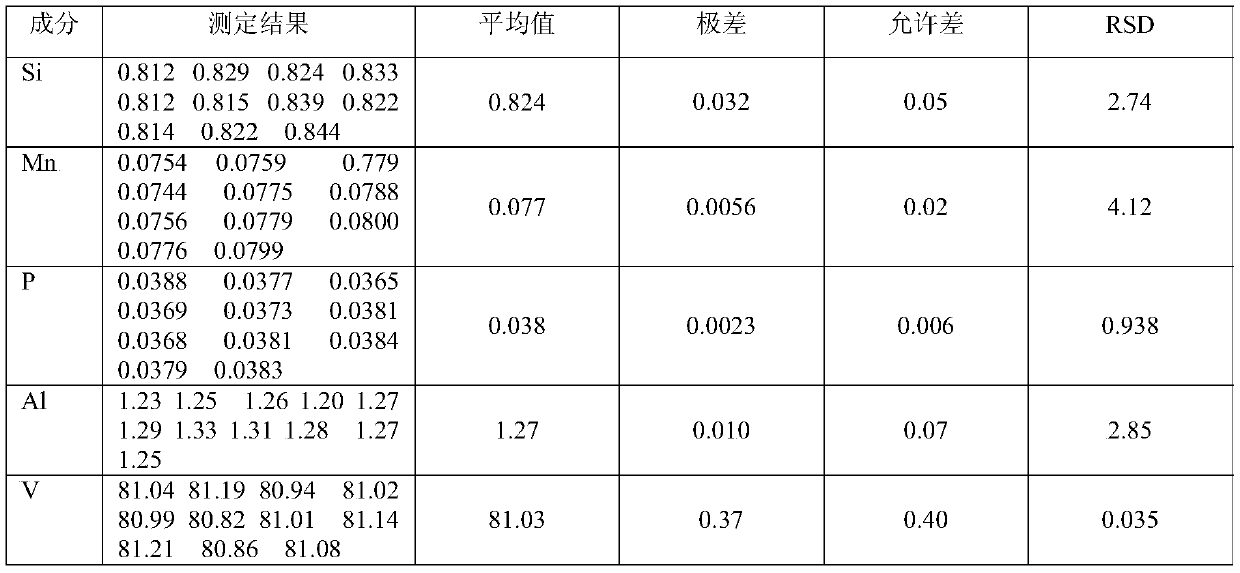

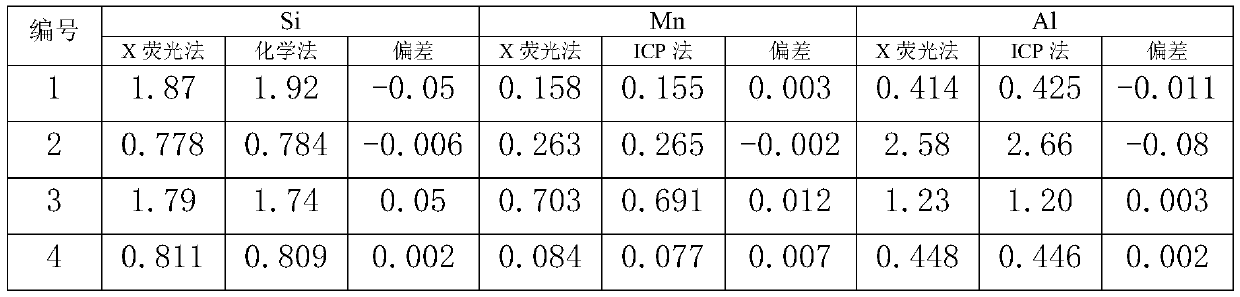

[0041] The determination of the amount of vanadium, silicon, aluminum, manganese and phosphorus in ferrovanadium is carried out by the following steps:

[0042] (1) The preparation of vanadium-iron glass frit is completed through the following steps

[0043] A. Accurately weigh 6.0000g of lithium tetraborate, 1.5000g of lithium carbonate, and 0.1500g of ferrovanadium sample in a filter paper bag, add about 0.7 ammonium nitrate, mix the analysis flux and the sample in the filter paper bag evenly, and wrap it into a spherical shape ;

[0044] B. Put the filter paper bag wrapped into a spherical shape into the porcelain crucible with graphite powder as the bottom in advance, put it into the muffle furnace, turn on the power supply of the muffle furnace, and set the sample pre-oxidation temperature. The procedure is as follows: the heating time of the first working step is 30min, the initial temperature rises from room temperature 25°C to 600°C (±10°C); the heating time of the se...

Embodiment 2

[0058] The determination of the amount of vanadium, silicon, aluminum, manganese and phosphorus in ferrovanadium is carried out by the following steps:

[0059] (1) The preparation of vanadium-iron glass frit is completed through the following steps

[0060] A. Accurately weigh 6.5000g of lithium tetraborate, 1.5000g of lithium carbonate, and 0.2000g of ferrovanadium sample in a filter paper bag, add about 1.5g of ammonium nitrate, mix the analysis flux and the sample in the filter paper bag, and wrap it into spherical

[0061] B. Put the filter paper bag wrapped into a spherical shape into the porcelain crucible with graphite powder as the bottom in advance, put it into the muffle furnace, turn on the power supply of the muffle furnace, and set the sample pre-oxidation temperature. The procedure is as follows: the heating time of the first working step is 20min, the initial temperature rises from 150°C to 600°C (±10°C); the heating time of the second step is 90min, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com