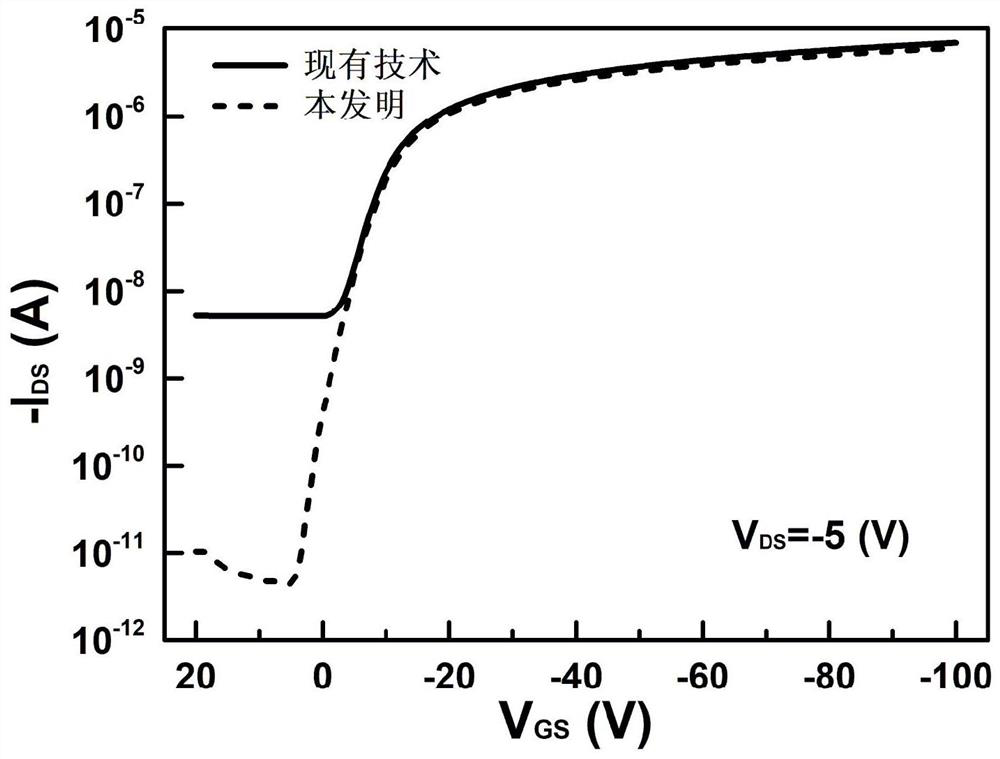

An organic thin film transistor with improved subthreshold swing and switching ratio and its preparation method

A sub-threshold swing, organic thin-film technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc. On/off ratio, good electrical performance, effect of reducing on-state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

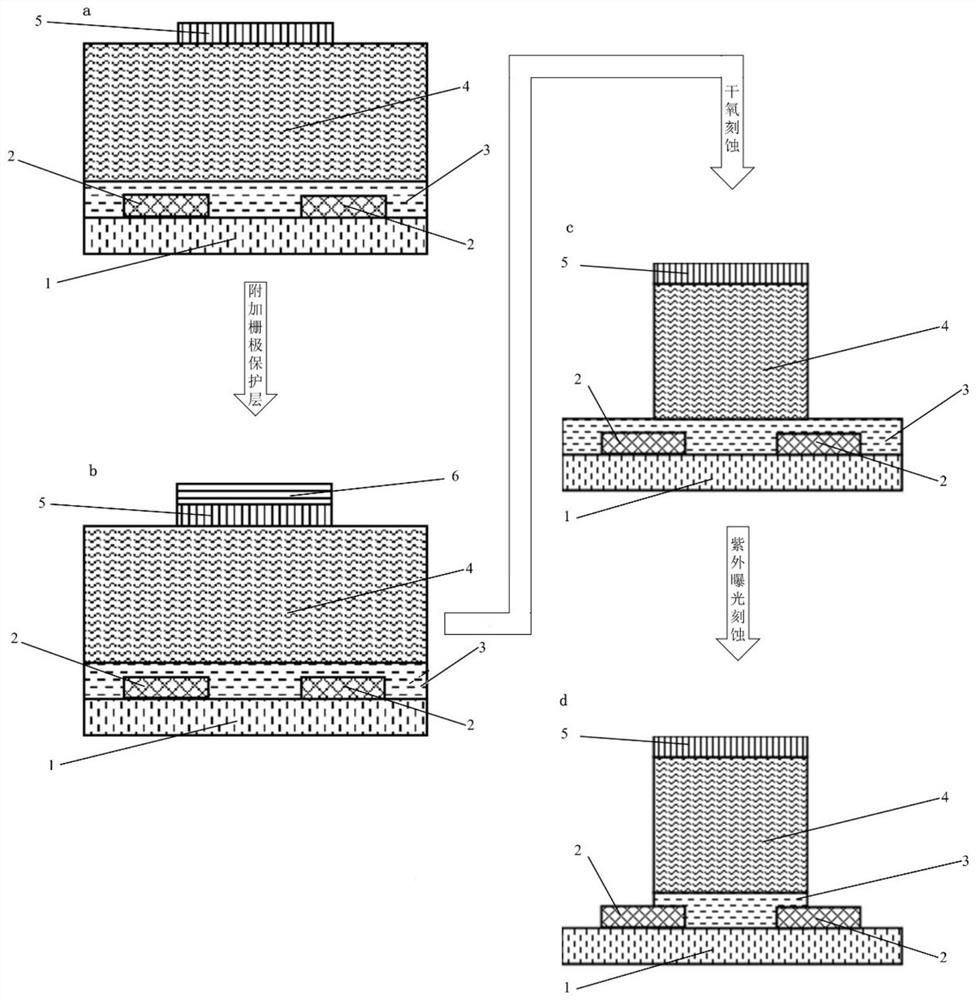

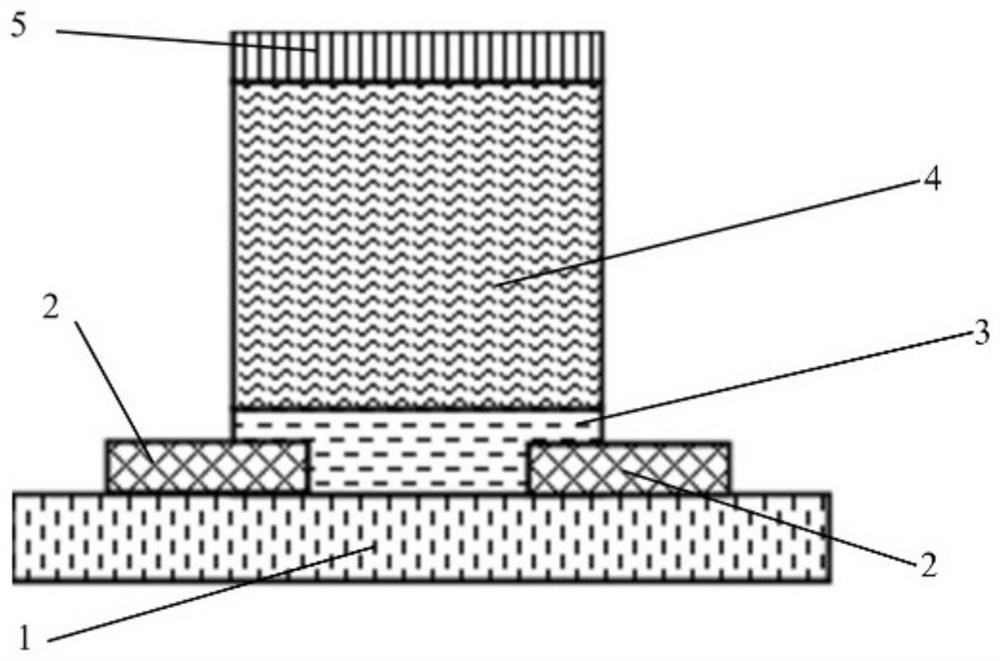

Method used

Image

Examples

Embodiment 1

[0053] Step 1: 1,4-dioxodipyrrole and thiophene polymer (DPPT-TT) was dissolved in dichlorobenzene at a ratio of 8 mg / ml, and stood on a heating plate at 70°C for 24 hours.

[0054] Step 2: Dissolve polymethyl methacrylate in butyl acetate at a ratio of 50 mg / ml and let stand on a heating plate at 70°C for 24 hours.

[0055] Step 3: Select a 1.5 cm x 1.5 cm glass slide as the substrate, ultrasonically clean it in deionized water, acetone, and isopropanol for 15 minutes, and finally dry it with a nitrogen gun.

[0056] Step 4: Using a vacuum thermal evaporation method, using a stainless steel mask, vapor-deposit gold electrodes with a length of 100 microns, a width of 1000 microns, and a thickness of 50 nanometers on the substrate as source and drain electrodes.

[0057] Step 5: Put the solution prepared in step 1, through a pipette gun, onto the glass slide treated in step 4, spin coating at 4500 rpm for 40 seconds, and place on the source and drain electrodes A semiconductor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com