Multi-response intelligent zinc-air battery and preparation method thereof

A multi-response, catalyst technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc., can solve the problems of high recharging cost, poor reactivity, and stimuli responsiveness. Achieve wide application value and prospects, simple structure, and the effect of reducing mass and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 Preparation of intelligent zinc-air battery with multiple responses

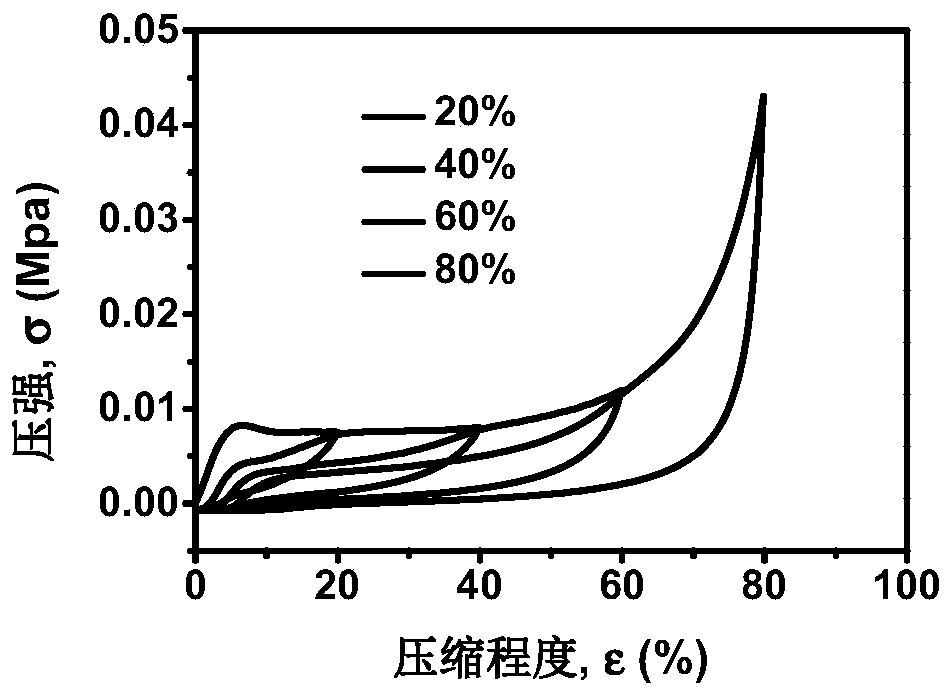

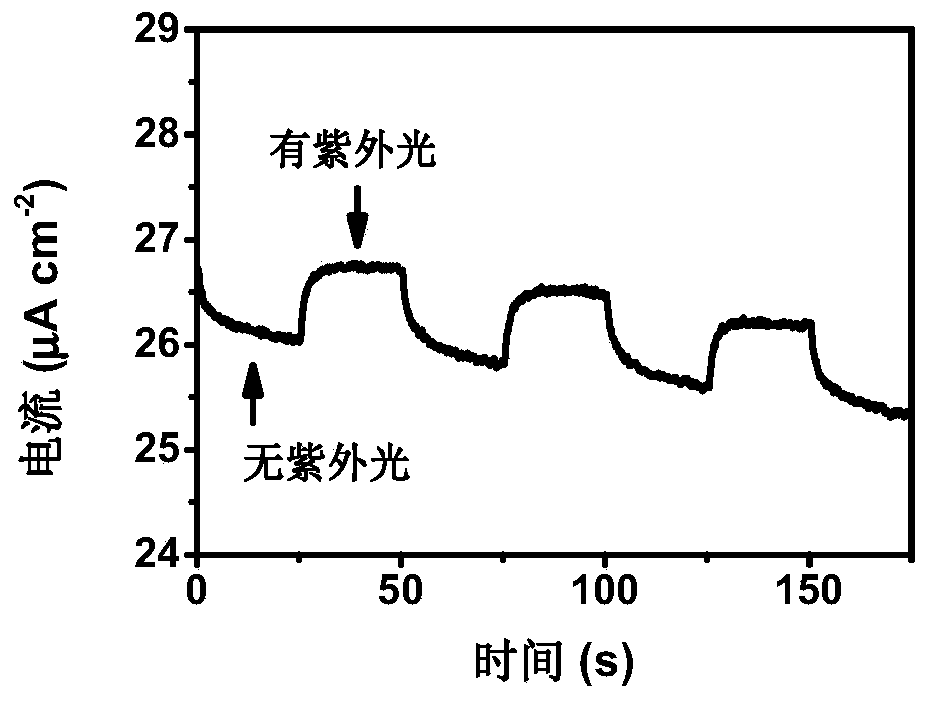

[0082] 1) Preparation of pressure, ultraviolet and sunlight multiple responsive foam cathodes

[0083] (1) Preparation of catalyst dispersion

[0084] Add the multi-walled carbon nanotubes to 6mol / L hydrochloric acid, stir and reflux for 9h, wash, filter, remove the residual metal impurities in the original carbon nanotubes, and then place them in an oven at 80°C to dry; the treated carbon nanotubes The tube and the block polymer PEDOT-b-PEO were mixed according to the mass ratio of 4:1, and ultrasonically dispersed in an ethanol solvent for 20 minutes to obtain a catalyst dispersion with a concentration of 0.6 mg / mL;

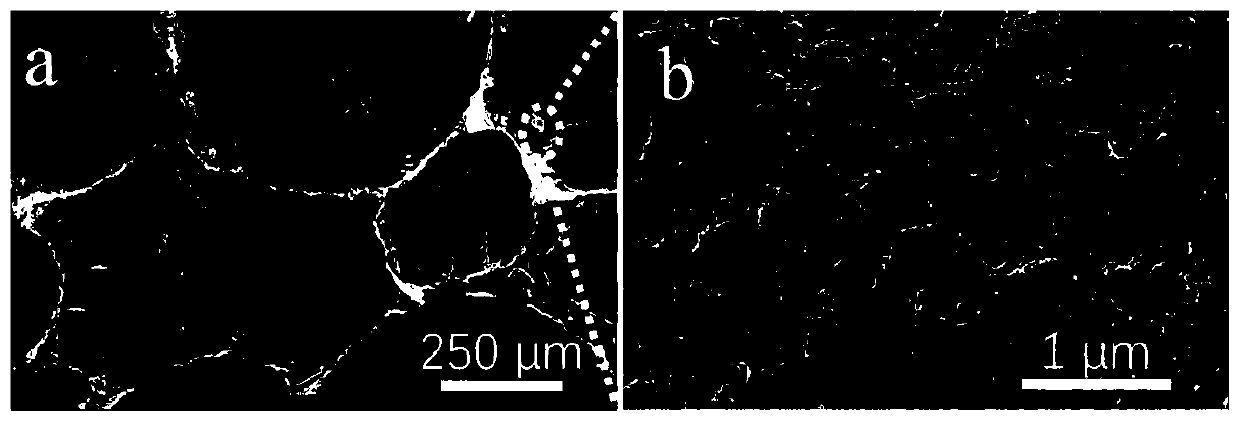

[0085] (2) Preparation of foam cathodes with multiple responses to pressure, ultraviolet light and sunlight

[0086] Soak the polyurethane elastic foam with the above catalyst dispersion, squeeze the elastic foam 3 times repeatedly to obtain the elastic foam containing t...

Embodiment 2

[0093] Example 2 Preparation of Intelligent Zinc-air Battery with Multiple Responses

[0094] 1) Preparation of pressure, ultraviolet and sunlight multiple responsive foam cathodes

[0095] (1) Preparation of catalyst dispersion

[0096] Add multi-walled carbon nanotubes to 4mol / L hydrochloric acid, stir and reflux for 6h, wash, filter, remove residual metal impurities in the original carbon nanotubes, and then place them in a 60°C oven to dry; the treated carbon nanotubes The tube and the block polymer PEDOT-b-PEO were mixed according to the mass ratio of 7:3, and ultrasonically dispersed in acetone solvent for 10 minutes to obtain a catalyst dispersion with a concentration of 0.1mg / mL;

[0097] (2) Preparation of foam cathodes with multiple responses to pressure, ultraviolet light and sunlight

[0098] Soak the melamine elastic foam with the above-mentioned catalyst dispersion, squeeze the elastic foam 5 times repeatedly to obtain the elastic foam containing the catalyst d...

Embodiment 3

[0105] Example 3 Preparation of Intelligent Zinc-air Battery with Multiple Responses

[0106] 1) Preparation of pressure, ultraviolet and sunlight multiple responsive foam cathodes

[0107] (1) Preparation of catalyst dispersion

[0108] Add commercial multi-walled carbon nanotubes to 8mol / L hydrochloric acid, stir and reflux for 12h, wash, filter, remove residual metal impurities in the original carbon nanotubes, and then place them in a 90°C oven to dry; the treated carbon Nanotubes and block polymer PEDOT-b-PEO were mixed according to the mass ratio of 9:1, and ultrasonically dispersed in water for 60 minutes to obtain a catalyst dispersion with a concentration of 4 mg / mL;

[0109] (2) Preparation of foam cathodes with multiple responses to pressure, ultraviolet light and sunlight

[0110] Soak the polystyrene elastic foam with the above catalyst dispersion, squeeze the elastic foam once repeatedly to obtain the elastic foam containing the catalyst dispersion; then dry at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com