Efficient special SNCR denitration device for petrochemical industry

A denitrification, industry-leading technology, applied in the field of high-efficiency SNCR denitration devices for the petrochemical industry, can solve the problems of high construction and operation costs, uneven distribution of liquid ammonia injection, damage to flue equipment, etc., to ensure spray coverage and reduce Effect of heat loss and corrosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

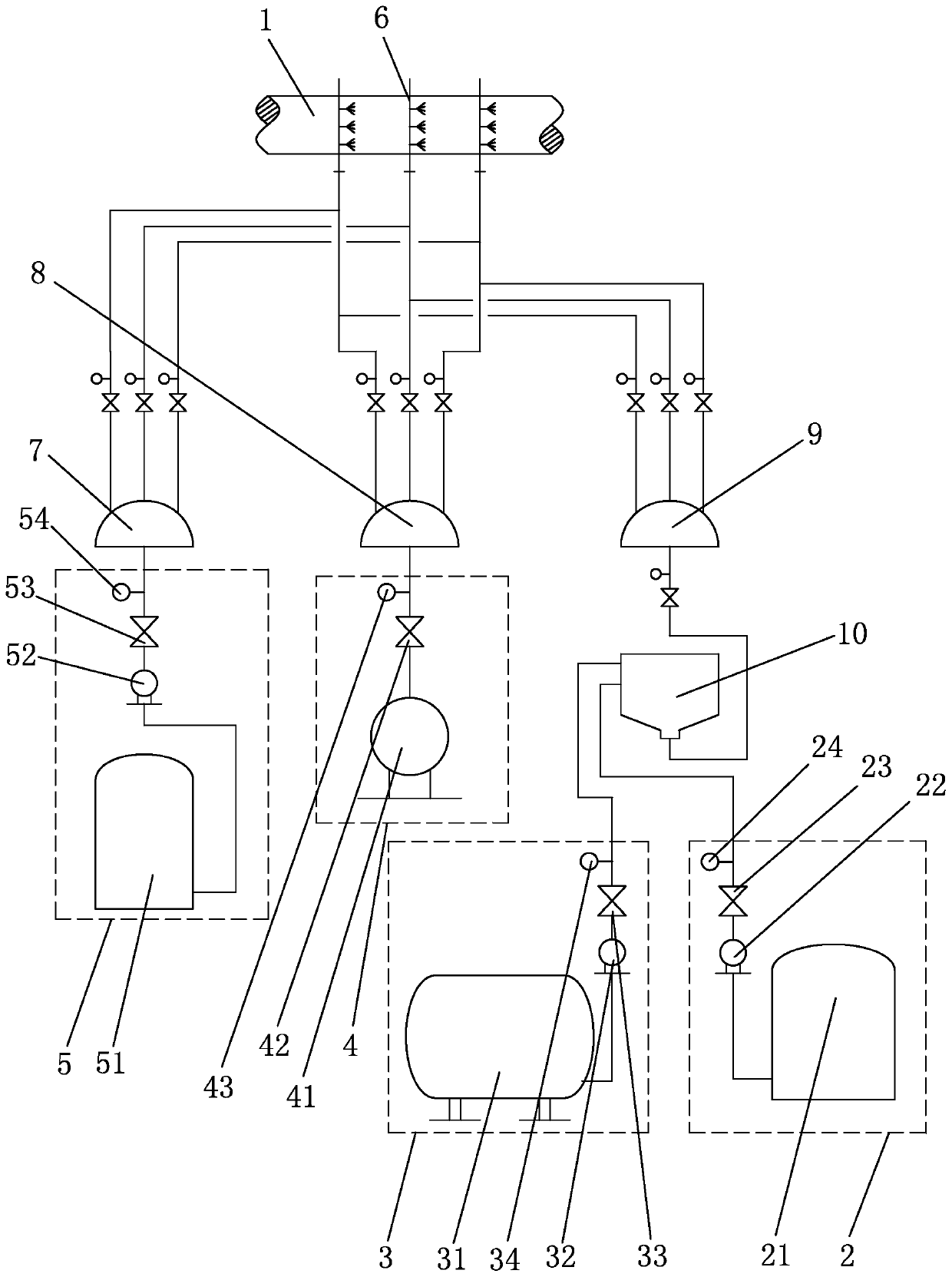

[0020] Such as figure 1 As shown, a high-efficiency SNCR denitrification device dedicated to the petrochemical industry includes a flue 1, a denitrification agent system 2, a dilution water system 3, an air compression system 4 and a cooling water system 5, and a suitable one is selected within the temperature range of 750-1100 °C. Spray gun installation location. According to the flow field and temperature field analysis, several SNCR denitrification spray guns 6 are provided, and each SNCR denitrification spray gun 6 is equipped with several nozzles. The cooling water system 5 is connected to the cooling water distributor 7, and the branch pipes of the cooling water distributor 7 are connected to the flue Several SNCR denitrification spray guns 6 in 1 are connected, the air compression system 4 is connected with an air distributor 8, and the branch pipes of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com