Preparation method of vertically-grown rhenium disulfide nanosheet

A rhenium disulfide, vertical growth technology, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc., can solve the problem of low deposition rate, and achieve the effect of simple preparation process, large quantity, and good electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

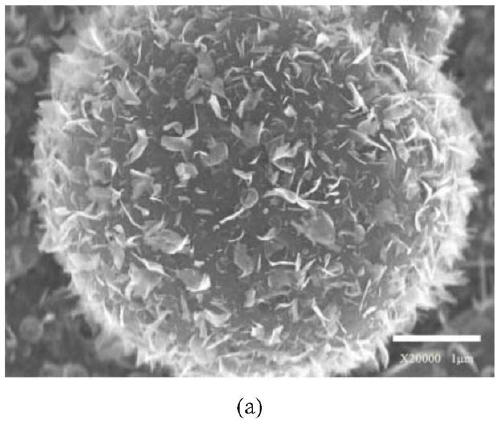

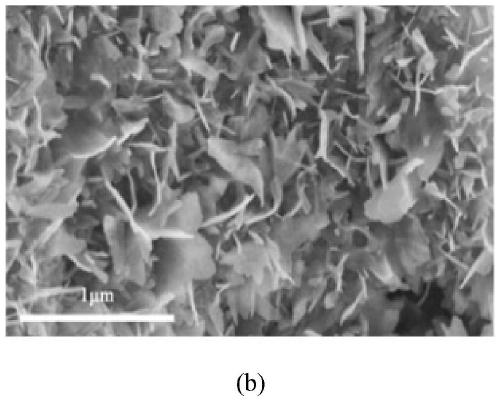

[0028] A preparation method for vertically grown rhenium disulfide nanosheets, comprising the following steps:

[0029] Step 1, pretreatment of silicon wafer A: ultrasonically clean silicon wafer A with a size of 1 cm×1.8 cm in absolute ethanol, isopropanol and acetone for 10 minutes, and dry it to obtain a pretreated silicon wafer;

[0030] Pretreatment of the carbon cloth substrate: the carbon cloth substrate with a size of 1.8cm×4.5cm was ultrasonically cleaned in absolute ethanol and deionized water for 10min and 5min respectively, and then dried in an oven at 60°C to obtain a pretreated carbon cloth substrate;

[0031] Step 2, weigh 2 mg of rhenium trioxide, spread it on the pretreated silicon wafer and then place it in the corundum boat, then spread the pretreated carbon cloth base on the corundum boat, and then cover the silicon wafer B on the pretreated On the carbon cloth base, vent holes are left at both ends of the reaction boat;

[0032] Weigh 500mg of sulfur powd...

Embodiment 2

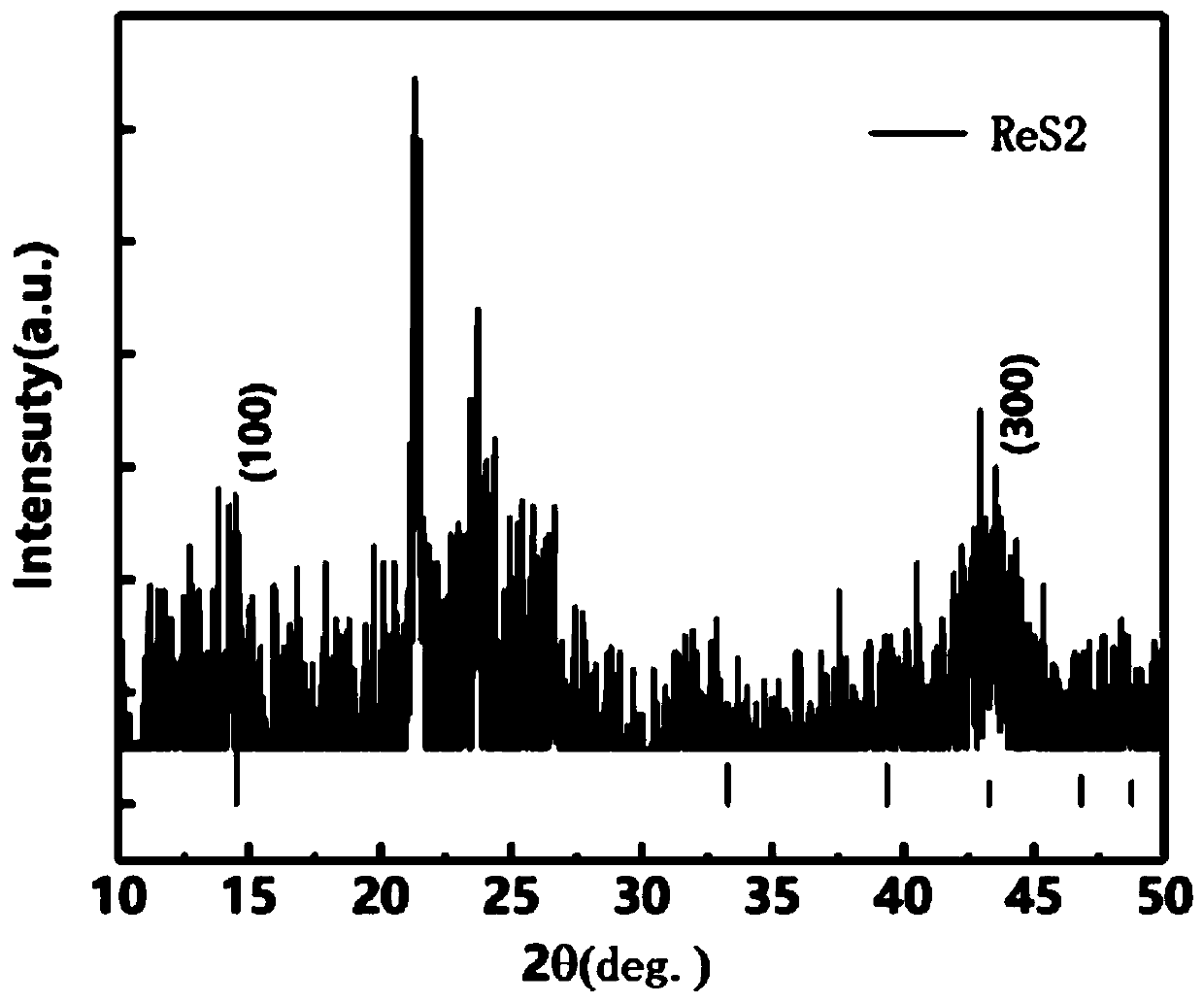

[0034] A preparation method of rhenium disulfide nanosheets grown vertically, the preparation method is the same as in Example 1, the difference is that in Example 2, the tubular furnace is heated to 700 °C at a heating rate of 30 °C / min, and vertical growth is obtained after 20 min. Grown rhenium disulfide nanosheets, the average size of the rhenium disulfide nanosheets is 20nm.

Embodiment 3

[0036] A preparation method of rhenium disulfide nanosheets grown vertically, the preparation method is the same as in Example 1, the difference is that in Example 3, the vacuum in the tube furnace is 1Pa, the argon flow rate is 80 sccm, and the tube furnace operates at 30°C The temperature was raised to 700° C. at a heating rate of / min, and vertically grown rhenium disulfide nanosheets were obtained after growing for 30 minutes. The average size of the rhenium disulfide nanosheets was 5 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com