Nano magnetic cationic flocculant and preparation method thereof

A cationic flocculant and nano-magnetic technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of long mud-water separation process, increased floor area, large sedimentation tank volume, etc., to speed up the settling speed and shorten the existence time , The effect of simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a nano-magnetic cationic flocculant, and its specific preparation steps are as follows:

[0046] Step 1: Graft Copolymerization and Fe Loading 3 o 4 Nanoparticles:

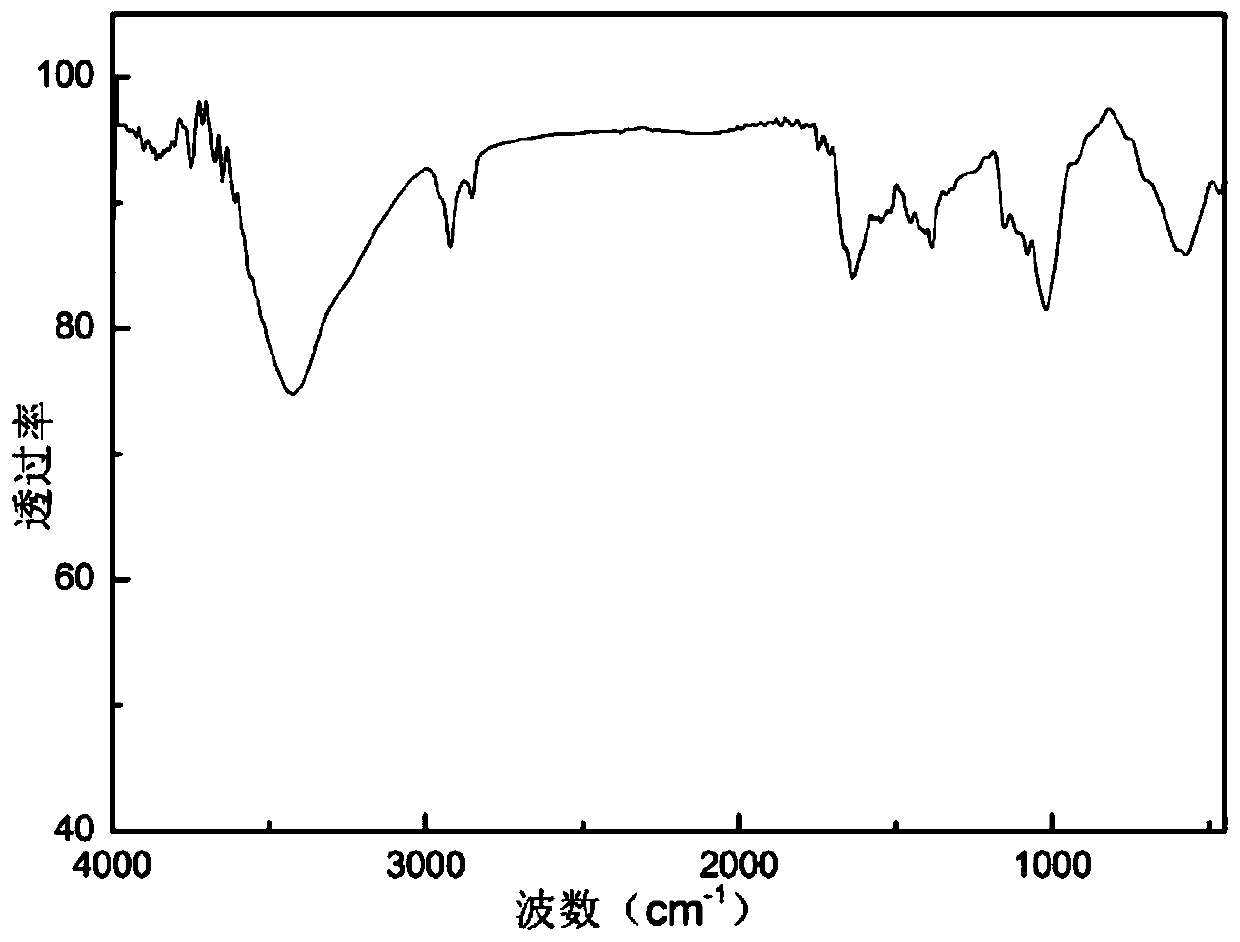

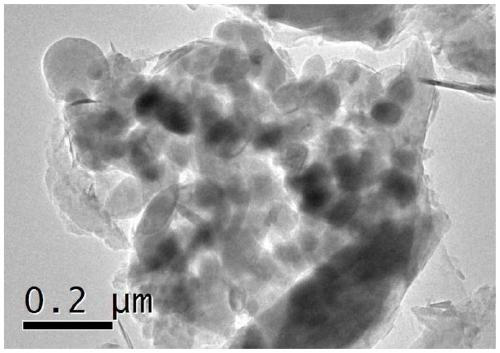

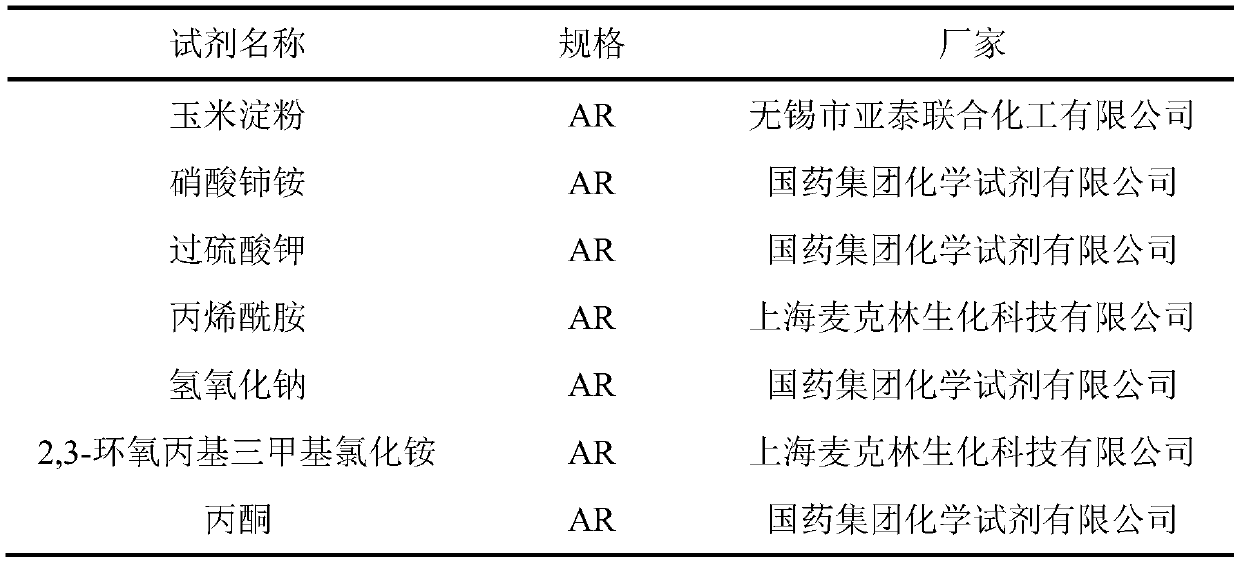

[0047] Weigh 5g of corn starch and 50mL of deionized water, gelatinize at a constant temperature of 70°C for 1 hour in a sealed state to obtain gelatinized starch, use an iron sheet as an anode and a carbon rod as a cathode, connect a DC power supply to build an electrolytic cell, add the gelatinized starch In the electrolytic cell, adjust the temperature of the reaction system to 60°C, dissolve 0.15g of cerium ammonium nitrate and 0.3g of potassium persulfate in 10mL of deionized water and add them to the reaction system as an initiating system, stir at 300r / min for 10min, and turn on the power At the same time, slowly add 20mL of 0.5g / mL acrylamide aqueous solution (the mass ratio of starch to acrylamide is 1:2), adjust the reaction system to 30°C, add NaOH solution dropwise to ...

Embodiment 2

[0054] This embodiment provides a nano-magnetic cationic flocculant, and its specific preparation steps are as follows:

[0055] Step 1: Graft Copolymerization and Fe Loading 3 o 4 Nanoparticles:

[0056] Weigh 5g of corn starch and 50mL of deionized water, gelatinize at a constant temperature of 70°C for 1 hour in a sealed state to obtain gelatinized starch, use an iron sheet as an anode and a carbon rod as a cathode, connect a DC power supply to build an electrolytic cell, add the gelatinized starch Into the electrolytic cell, adjust the temperature of the reaction system to 60°C, dissolve 0.15g of cerium ammonium nitrate and 0.3g of potassium persulfate in 10mL of deionized water and add them to the reaction system as an initiating system, stir for 10min, turn on the power and slowly add 20mL 0.5g / mL acrylamide aqueous solution (mass ratio of starch to acrylamide is 1:2), adjust the reaction system to 30°C, add NaOH solution dropwise to adjust the pH value to 12, then adj...

Embodiment 3

[0063] This embodiment provides a nano-magnetic cationic flocculant, and its specific preparation steps are as follows:

[0064] Step 1: Graft Copolymerization and Fe Loading 3 o 4 Nanoparticles:

[0065] Weigh 5g of corn starch and 50mL of deionized water, gelatinize at a constant temperature of 70°C for 1 hour in a sealed state to obtain gelatinized starch, use an iron sheet as an anode and a carbon rod as a cathode, connect a DC power supply to build an electrolytic cell, add the gelatinized starch In the electrolytic cell, adjust the temperature of the reaction system to 60°C, dissolve 0.15g of cerium ammonium nitrate and 0.3g of potassium persulfate in 10mL of deionized water and add them to the reaction system as an initiating system, stir at 300r / min for 10min, and turn on the power At the same time, slowly add 20mL of 0.75g / mL acrylamide aqueous solution (the mass ratio of starch to acrylamide is 1:3), adjust the reaction system to 30°C, add NaOH solution dropwise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com