A kind of method adopting red mud to separate waste lithium battery cathode material and aluminum foil

A cathode material, lithium battery technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve problems such as equipment corrosion and environmental pollution, and achieve the effect of reducing anti-corrosion costs, reducing air pollution, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Firstly, the collected waste ternary lithium batteries were intensively charged and discharged in sodium chloride solution to prevent possible explosive reactions during manual disassembly. Then use tools to break the metal shell of the discarded lithium battery, and manually disassemble to obtain the positive pole piece, negative pole piece, separator and metal shell. Dry the positive pole piece in an oven at 80 degrees as a spare raw material for the next step.

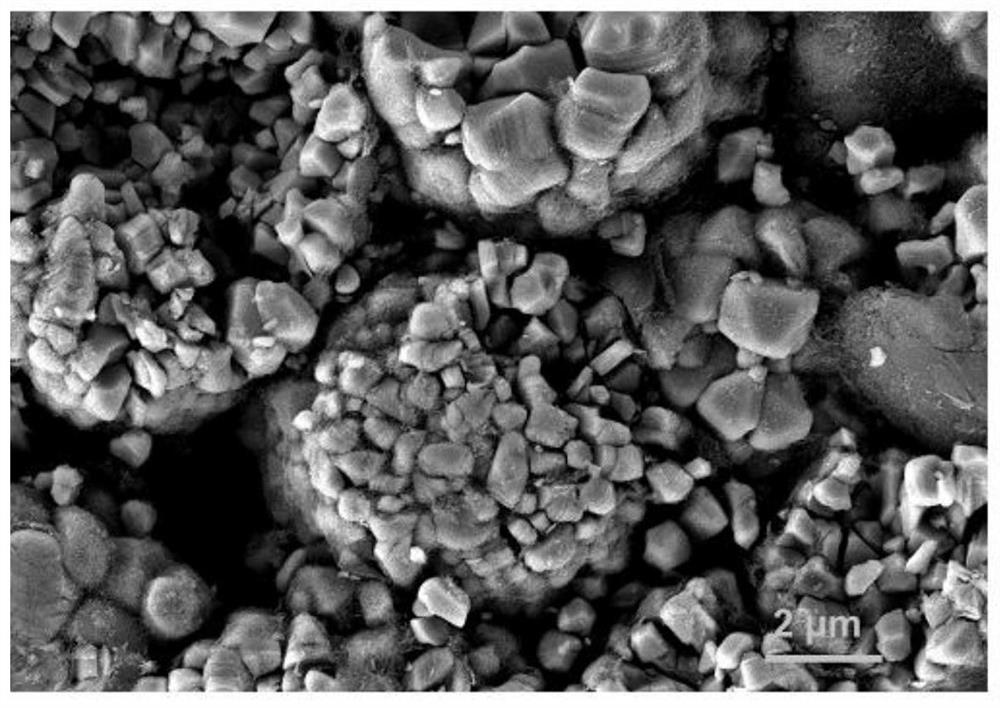

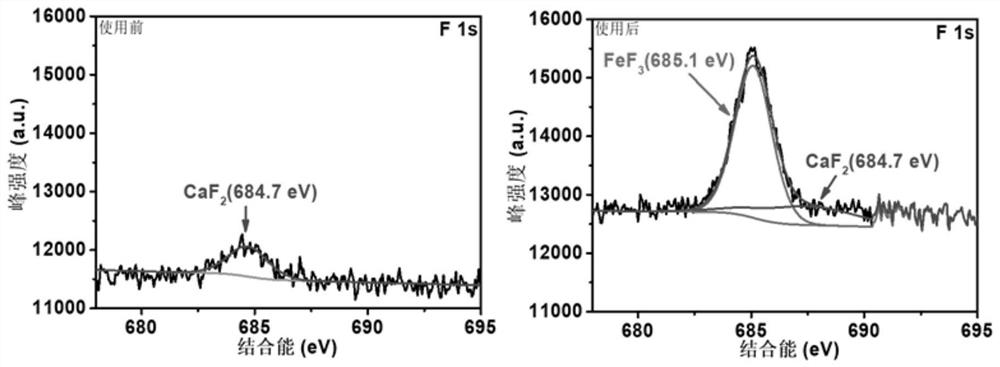

[0031] Mix the red mud powder and the obtained positive pole piece uniformly at a mass ratio of 2:1 and put them into a quartz boat, place the quartz boat in a tube furnace for a thermal reaction at 300 degrees for 30 minutes, and decompose the organic adhesive in the positive pole piece. binder polyvinylidene fluoride. After the reaction is completed, the tube furnace is naturally cooled down. After the temperature is lowered to room temperature, the positive electrode piece is taken out from the reaction m...

Embodiment 2

[0035] Firstly, the collected waste ternary lithium batteries were intensively charged and discharged in sodium chloride solution to prevent possible explosive reactions during manual disassembly. Then use tools to break the metal shell of the discarded lithium battery, and manually disassemble to obtain the positive pole piece, negative pole piece, separator and metal shell. Dry the positive pole piece in an oven at 80 degrees as a spare raw material for the next step. Mix the red mud powder and the positive electrode piece of the waste lithium battery evenly at a mass ratio of 1:1 and put it into a quartz boat, place the quartz boat in a tube furnace for a thermal reaction at 350 degrees for 30 minutes, and decompose the positive electrode piece Organic binder polyvinylidene fluoride. After the reaction is completed, the tube furnace is naturally cooled down. After the temperature is lowered to room temperature, the positive electrode piece is taken out from the reaction me...

Embodiment 3

[0037] Firstly, the collected waste ternary lithium batteries were intensively charged and discharged in sodium chloride solution to prevent possible explosive reactions during manual disassembly. Then use tools to break the metal shell of the discarded lithium battery, and manually disassemble to obtain the positive pole piece, negative pole piece, separator and metal shell. Dry the positive pole piece in an oven at 80 degrees as a spare raw material for the next step. Mix the red mud powder and the positive pole piece of the waste lithium battery evenly at a mass ratio of 3:1 and put them into a quartz boat, put the quartz boat in a tube furnace for a thermal reaction at 300 degrees for 20 minutes, and decompose the positive pole piece Organic binder polyvinylidene fluoride. After the reaction is completed, the tube furnace is naturally cooled down. After the temperature is lowered to room temperature, the positive electrode piece is taken out from the reaction medium red m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com