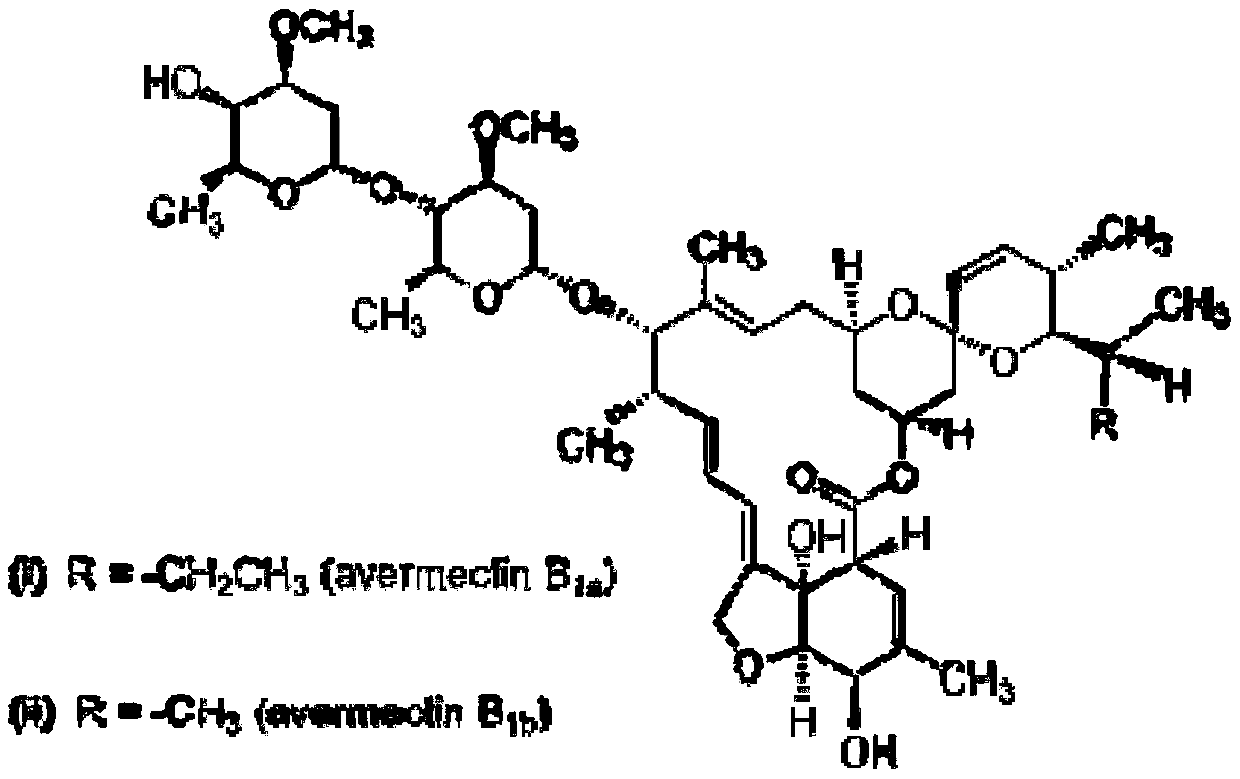

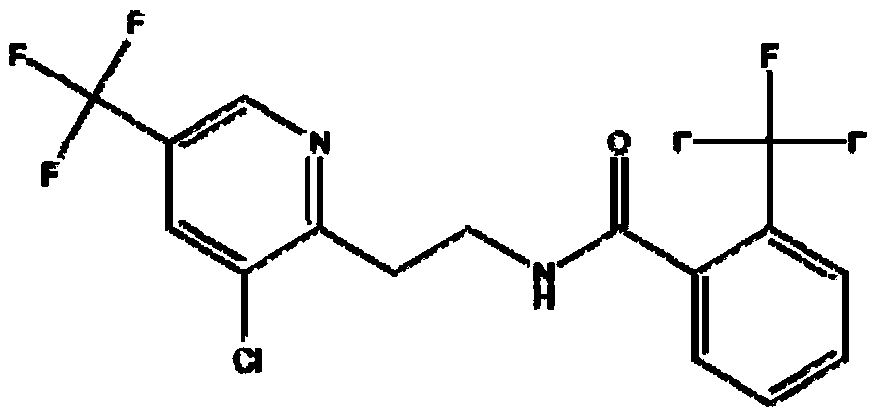

Microcapsule suspension-suspending agent containing avermectin and fluopyram, and preparation method thereof

A technology of fluopyram and microcapsule suspension, which is applied in the field of pesticide preparation, can solve the problems of organic solvent pollution, easy failure of abamectin, and agglomeration and solidification of preparations, so as to increase storage stability and increase the durability of preparations. The effect of validity period and extended storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present disclosure: a method for preparing a microcapsule suspension-suspension containing abamectin and fluopyram is provided, the method comprising:

[0022] a. Mix the oil phase material with the water phase material to obtain an O / W type emulsion; wherein, the weight ratio of the oil phase material to the water phase material is 1: (0.5~5), and the oil phase material contains A Vermectin, organic solvent and macromolecule wall material, contain water and emulsifying agent in the described aqueous phase material; B, remove the organic solvent in the described O / W type emulsion, obtain avermectin microcapsule suspension; c , the Abamectin microcapsule suspension is mixed with the first dispersant, the first thickener and the first antifreeze agent to obtain the Abamectin microcapsule suspension; d, the Abamectin microcapsule suspension The capsule suspension is mixed with the fluopyram suspension to obtain the abamectin-fluopyram microcapsule s...

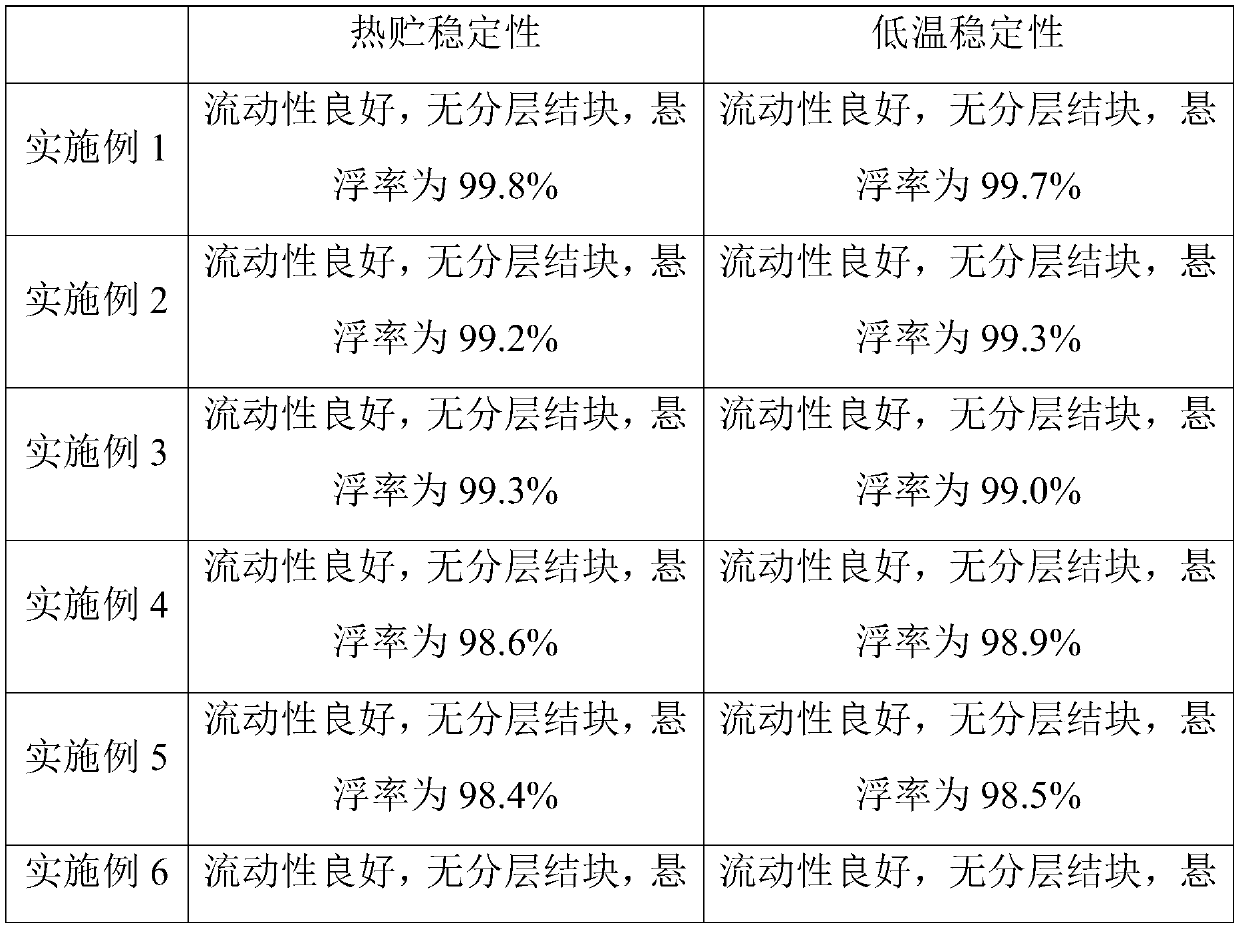

Embodiment 1

[0058] Prepare a kind of microcapsule suspension-suspension concentrate containing Abamectin and Fluopyram, specifically as follows:

[0059] 1) Abamectin and polymethyl methacrylate are dissolved in dichloromethane to obtain an oil phase material, wherein the weight ratio of abamectin, dichloromethane and polymethyl methacrylate is 1: 7:0.15;

[0060] Dissolving polyvinyl alcohol in water to obtain a water phase material, wherein the weight ratio of water to polyvinyl alcohol is 1:0.12;

[0061] Mix the above-mentioned oil phase material and water phase material and shear at a rate of 20,000 rpm for 7 minutes to obtain an O / W emulsion, wherein the weight ratio of the oil phase material to the water phase material is 1:1.5;

[0062] 2) Stir the above-mentioned O / W emulsion at a stirring rate of 250 rpm and 60° C. for 2.5 hours, volatilize and remove the organic solvent, and prepare the abamectin microcapsule suspension;

[0063] 3) above-mentioned abamectin suspension is mix...

Embodiment 2

[0068] Prepare a kind of microcapsule suspension-suspension concentrate containing Abamectin and Fluopyram, specifically as follows:

[0069] 1) Dissolving abamectin and polypropylene carbonate in chloroform to obtain an oil phase material, wherein the weight ratio of abamectin, chloroform and polypropylene carbonate is 1:5: 0.1;

[0070] Sodium dodecylbenzenesulfonate is dissolved in water to obtain a water phase material, wherein the weight ratio of water to sodium dodecylbenzenesulfonate is 1:0.1;

[0071] Mix the above-mentioned oil phase material and water phase material and shear at a rate of 10,000 rpm for 15 minutes to obtain an O / W emulsion, wherein the weight ratio of the oil phase material to the water phase material is 1:1;

[0072] 2) stirring the above-mentioned O / W emulsion at a stirring rate of 200 rpm and 30° C. for 4 hours, volatilizing and removing the organic solvent, and preparing the abamectin microcapsule suspension;

[0073] 3) Mix the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com