Preparation method of sodium-free fly ash-based ZSM-5 molecular sieve

A technology of ZSM-5 and fly ash, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of alkaline waste liquid discharge and cumbersome synthesis process, and achieve reduction Discharge of waste lye, wide range of sources of raw materials, and the effect of reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

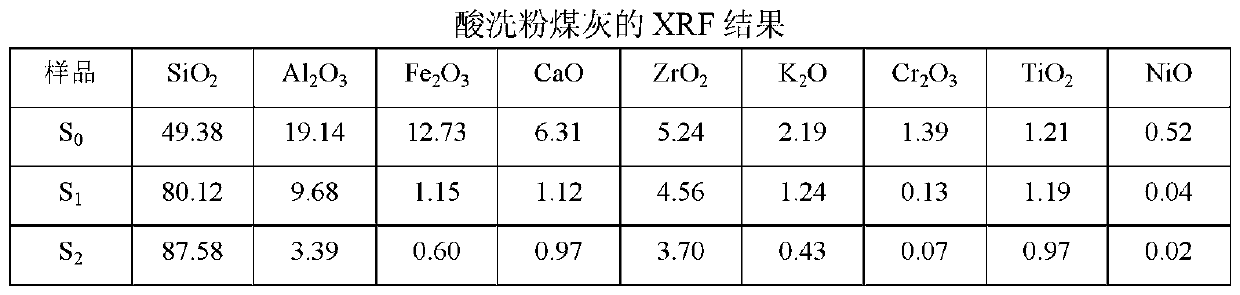

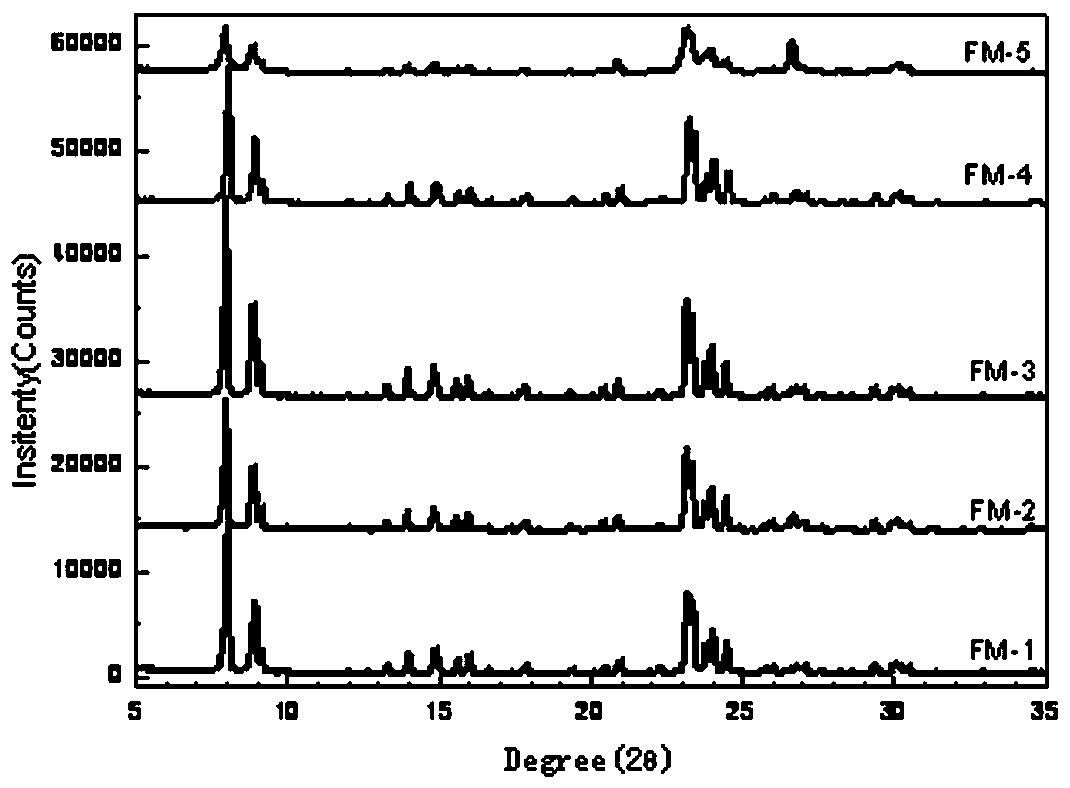

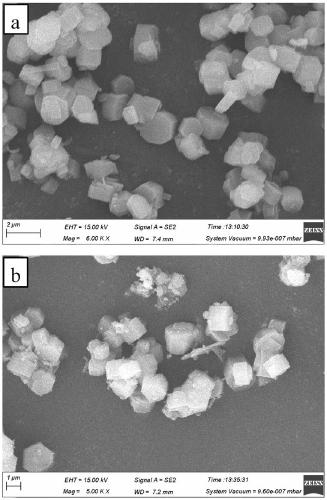

[0022] First, take a certain amount of fly ash, ball mill it and then calcined to obtain calcined fly ash S 0 , then add distilled water and hydrochloric acid in the reaction kettle for 12 hours of hydrothermal reaction at 150°C, wash and dry to obtain acid-washed fly ash S 1 (mass ratio is M 蒸馏水 :M 粉煤灰 :M 盐酸 =1:0.5:2.5); take a certain amount of pickling fly ash S 1 , white carbon black, distilled water and tetrapropyl ammonium hydroxide (TPAOH) are placed in the reactor (mass ratio is M 白炭黑 : M 酸洗粉煤灰S1 =10:59), stirred for 2 hours, placed in a high-temperature oven at 180°C, crystallized for 48 hours, taken out, washed until neutral, dried, placed in a muffle furnace and calcined at 550°C for 5 hours to remove the template agent, and obtained ZSM-5 molecular sieve, denoted as FM-1. The ratio of the amount of material to be added is 200SiO 2 :1Al 2 o 3 :0.3TPAOH:20H 2 O.

Embodiment 2

[0024] First, take a certain amount of fly ash, ball mill it and then calcined to obtain calcined fly ash S 0 , then add distilled water and hydrochloric acid in the reaction kettle for 12 hours of hydrothermal reaction at 150°C, wash and dry to obtain acid-washed fly ash S 1 (mass ratio is M 蒸馏水 :M 粉煤灰 :M 盐酸 =1:0.5:2.5). Take a certain amount of pickling fly ash S 1 , white carbon black, distilled water and tetrapropyl ammonium hydroxide (TPAOH) are placed in the reactor (mass ratio is M 白炭黑 : M 酸洗粉煤灰S1=4:89), stirred for 2 hours, placed in a high-temperature oven at 180°C, crystallized for 48 hours, taken out, washed until neutral, dried, placed in a muffle furnace and calcined at 550°C for 5 hours to remove the template agent, and obtained ZSM-5 molecular sieve, denoted as FM-2. The ratio of the amount of material to be added is 100SiO 2 :1Al 2 o 3 :0.3TPAOH:20H 2 O.

Embodiment 3

[0026] First, take a certain amount of fly ash, ball mill it and then calcined to obtain calcined fly ash S 0 , then add distilled water and hydrochloric acid in the reaction kettle for 12 hours of hydrothermal reaction at 150°C, wash and dry to obtain acid-washed fly ash S 1 (The mass ratio is: M 蒸馏水 :M 粉煤灰 :M 盐酸 =1:0.5:2.5). Take a certain amount of pickling fly ash S 1 , silica sol (w=30%), distilled water and tetrapropyl ammonium hydroxide (TPAOH) are placed in the reactor (mass ratio is M 硅溶胶 :M 酸洗粉煤灰S1 =35:29), stirred for 2 hours, placed in a high-temperature oven at 180°C, crystallized for 48 hours, taken out, washed until neutral, dried, placed in a muffle furnace and calcined at 550°C for 5 hours to remove the template agent, and obtained ZSM-5 molecular sieve, denoted as FM-3. The ratio of the amount of material to be added is 100SiO 2 :1Al 2 o 3 :0.3TPAOH:20H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com