Thermal power industry water resource high efficiency utilization integrated method

An integrated method and technology of water resources, applied in the integrated field of efficient utilization of water resources in the thermal power industry, can solve the problems of no further treatment and reuse facilities, large water consumption, and large water consumption, so as to reduce process treatment facilities and save water costs. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with specific embodiments.

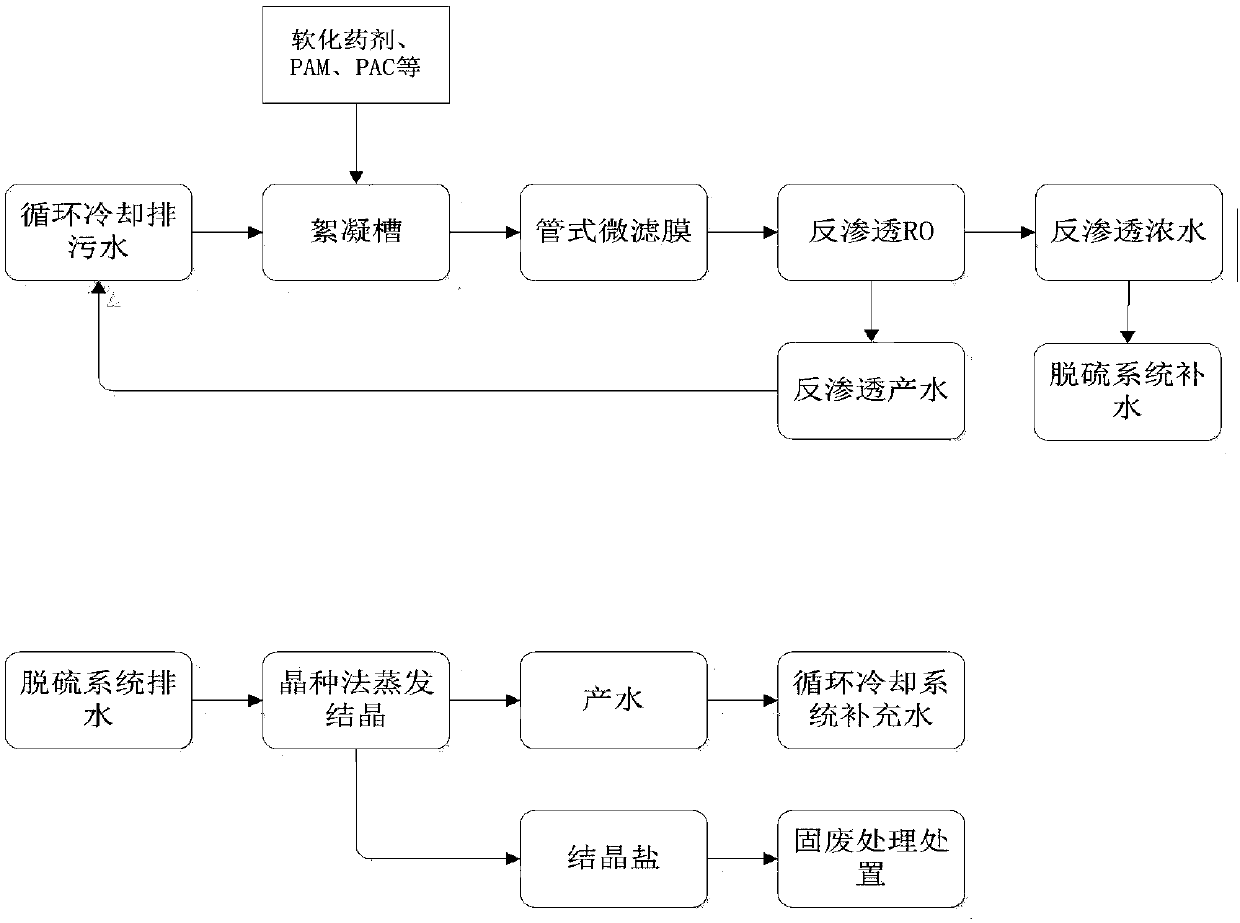

[0033] An integrated method for efficient utilization of water resources in the thermal power industry proposed by the present invention comprises the following steps:

[0034] S1. Circulating water pretreatment: add softening agent in the flocculation tank for pretreatment;

[0035] S2, tubular microfiltration membrane filtration: pass the water in S1 into the tubular microfiltration membrane;

[0036] S3, reverse osmosis filtration: pass the water in S2 into the reverse osmosis system;

[0037] S4. Desulfurization water pretreatment: pretreat the desulfurization system drainage and pass it into the evaporation and crystallization equipment.

[0038] The softening agents in the step S1 are PAC and PAM.

[0039] In the step S2, the pore size of the tubular microfiltration membrane is 0.1-1 μm, the material is synthetic polymer membrane PVDF, the operating pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com