10 kg-grade production method of 2,6-diamino-1-oxopyrazine

A production method and technology of oxypyrazine, which is applied in the field of synthesis of pyrazine compounds, can solve the problems of high reaction temperature, complex synthesis process conditions, and many impurities, and achieve mild reaction process, good process safety, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] To make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below. If specific conditions are not indicated in the examples, it shall be carried out in accordance with conventional conditions or conditions recommended by the manufacturer. The reagents or instruments used without the manufacturer's indication are all conventional products that can be purchased commercially.

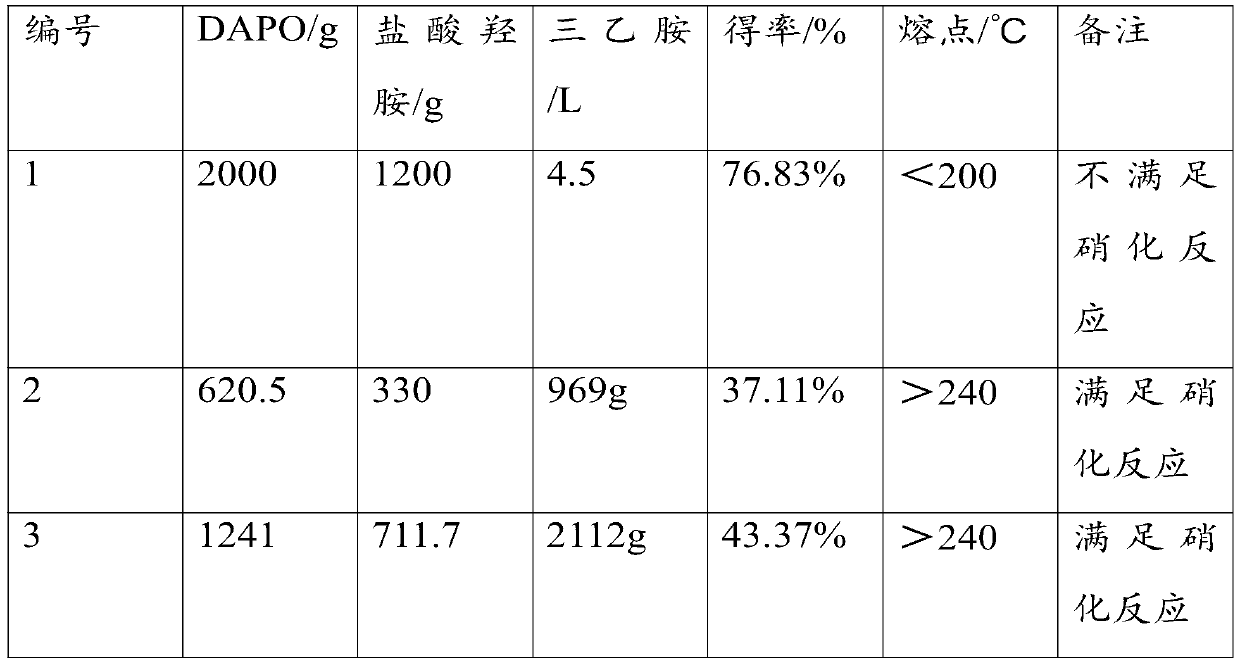

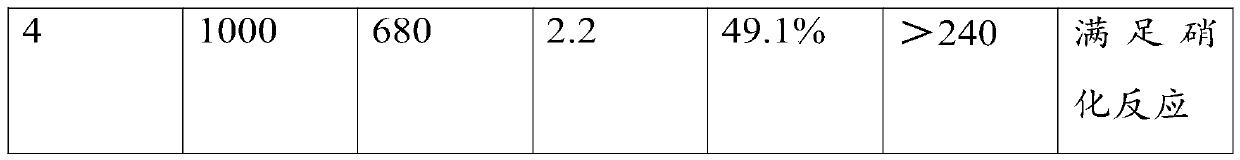

[0020] The invention provides a 10 kilogram production method of 2,6-diamino-1-oxypyrazine. The raw materials of the production method include the following components by weight: Main ingredients: 10-15 parts of iminodiacetonitrile, 10-15 parts of sodium nitrite, 10-15 parts of concentrated sulfuric acid, 50-80 parts of anhydrous methanol, triethyl 30-50 parts of amine, 10-15 parts of hydroxylamine hydrochloride. Accessories: 5-10 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com