Preparation method of high-slip-resistance low-wear thermoplastic polyurethane elastomer

A thermoplastic polyurethane, low-wear technology, applied in the field of polyurethane elastomer preparation, can solve the problem of wear resistance not meeting the needs of special occasions, and achieve the best effect of reducing wear and meeting the needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 500 g of polyols prepared by tetrahydrofuran ring-opening polymerization, 10 g of a mixture of molybdenum disulfide and methyl silicone oil, and tetrakis (4-hydroxy-3,5-tert-butylphenylpropionic acid) into a 2-liter 90°C reactor. ) 0.5g of pentaerythritol ester, vacuumized and dehydrated, keeping the vacuum at -0.098MPa, kept for 1 hour to form a modified polyol;

[0028] SiO 2 Put it in an oven in advance and activate it at 100°C to get activated SiO 2 (P-SiO 2 ), the 6g P-SiO 2 Place in a three-necked flask, add an appropriate amount of toluene, stir quickly to make it evenly dispersed, add isocyanate-toluene solution drop by drop under nitrogen protection, add 4 to 5 drops of dibutyltin dilaurate, and stir at 80°C for 10 hours , filtered with suction, washed with toluene to remove the unreacted isocyanate adsorbed on the surface, and the filtrate was titrated according to the ISO 14896-2009 standard until there was no isocyanate in the filtrate, and the filter...

Embodiment 2

[0032] Add 500 g of polyols prepared by tetrahydrofuran ring-opening polymerization, 15 g of a mixture of molybdenum disulfide and methyl silicone oil, and tetrakis (4-hydroxy-3,5-tert-butylphenylpropionic acid) into a 2-liter 95 ° C reactor. ) 1g of pentaerythritol ester, vacuumized and dehydrated, keeping the vacuum at -0.099MPa, kept for 2 hours to form a modified polyol;

[0033] SiO 2 Put it in an oven in advance and activate it at 100°C for 4 hours to obtain activated SiO 2 (P-SiO 2 ); the 6g P-SiO 2 Place in a three-necked flask, add an appropriate amount of toluene, stir rapidly to distribute it evenly, add isocyanate-toluene solution drop by drop under nitrogen protection, add 4 to 5 drops of dibutyltin dilaurate, and stir at 80°C for 10 hours. , filtered with suction, washed with toluene to remove the unreacted isocyanate adsorbed on the surface, and the filtrate was titrated according to the ISO 14896-2009 standard until there was no isocyanate in the filtrate, a...

Embodiment 3

[0037] Add 500 g of polyols prepared by tetrahydrofuran ring-opening polymerization, 5 g of a mixture of molybdenum disulfide and methyl silicone oil, and tetrakis (4-hydroxy-3,5-tert-butylphenylpropionic acid) into a 2-liter 90 ° C reactor. 0.3g of pentaerythritol ester, vacuum dehydration, keep the vacuum at -0.1MPa, and keep warm for 1.5 hours to form a modified polyol;

[0038] SiO 2 Put it in an oven in advance and activate it at 100°C for 5 hours to obtain activated SiO 2 (P-SiO 2 ); the 6g P-SiO 2 Place in a three-necked flask, add an appropriate amount of toluene, stir quickly to make it evenly dispersed, add isocyanate-toluene solution drop by drop under nitrogen protection, add 4 to 5 drops of dibutyltin dilaurate, and stir at 80°C for 10 hours , filtered with suction, washed with toluene to remove the unreacted isocyanate adsorbed on the surface, and the filtrate was titrated according to the ISO 14896-2009 standard until there was no isocyanate in the filtrate, ...

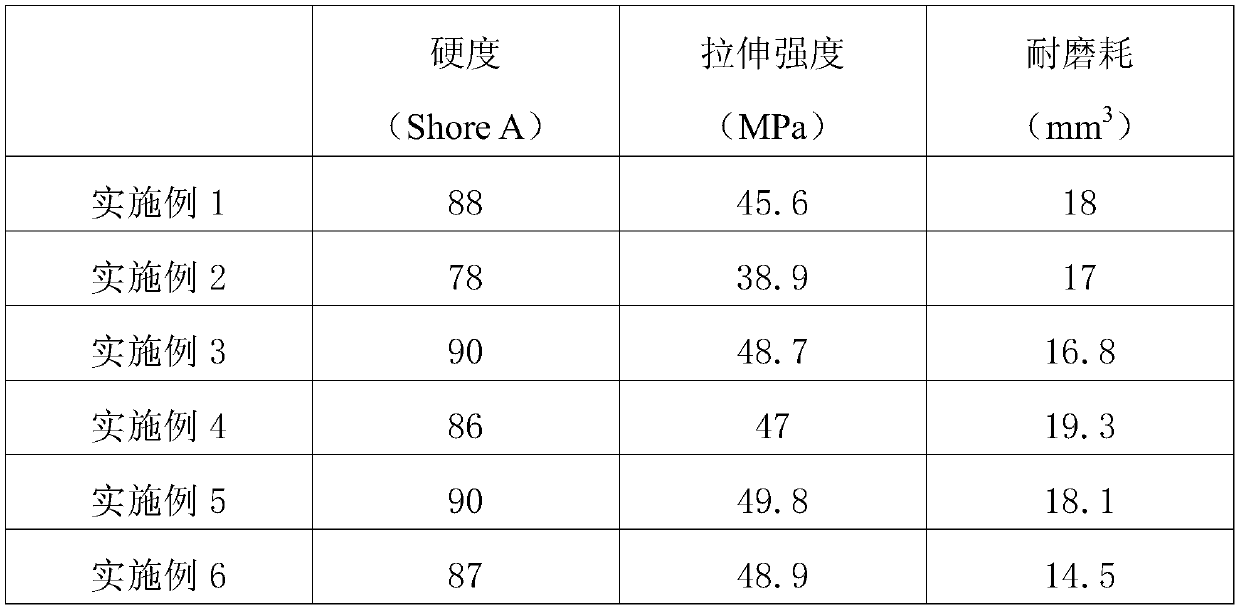

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com