Insulin pen placement device

A technology for placing insulin pens and holes, which is applied in the field of medical devices, can solve problems such as cumbersomeness, knocking of insulin pens, troublesome work of medical staff, etc., and achieve the effects of good viewing angle, stable working performance, and convenient and accurate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

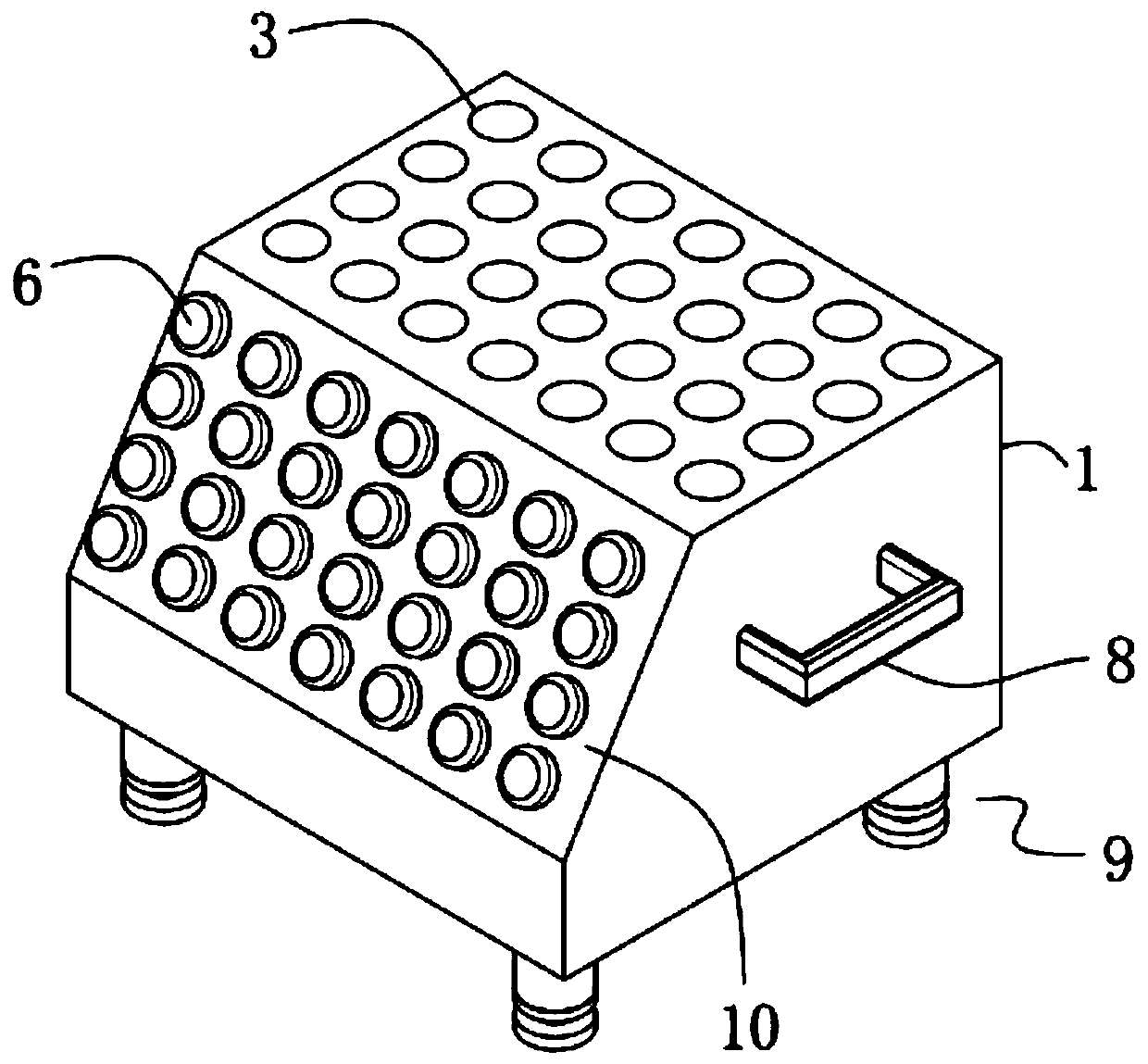

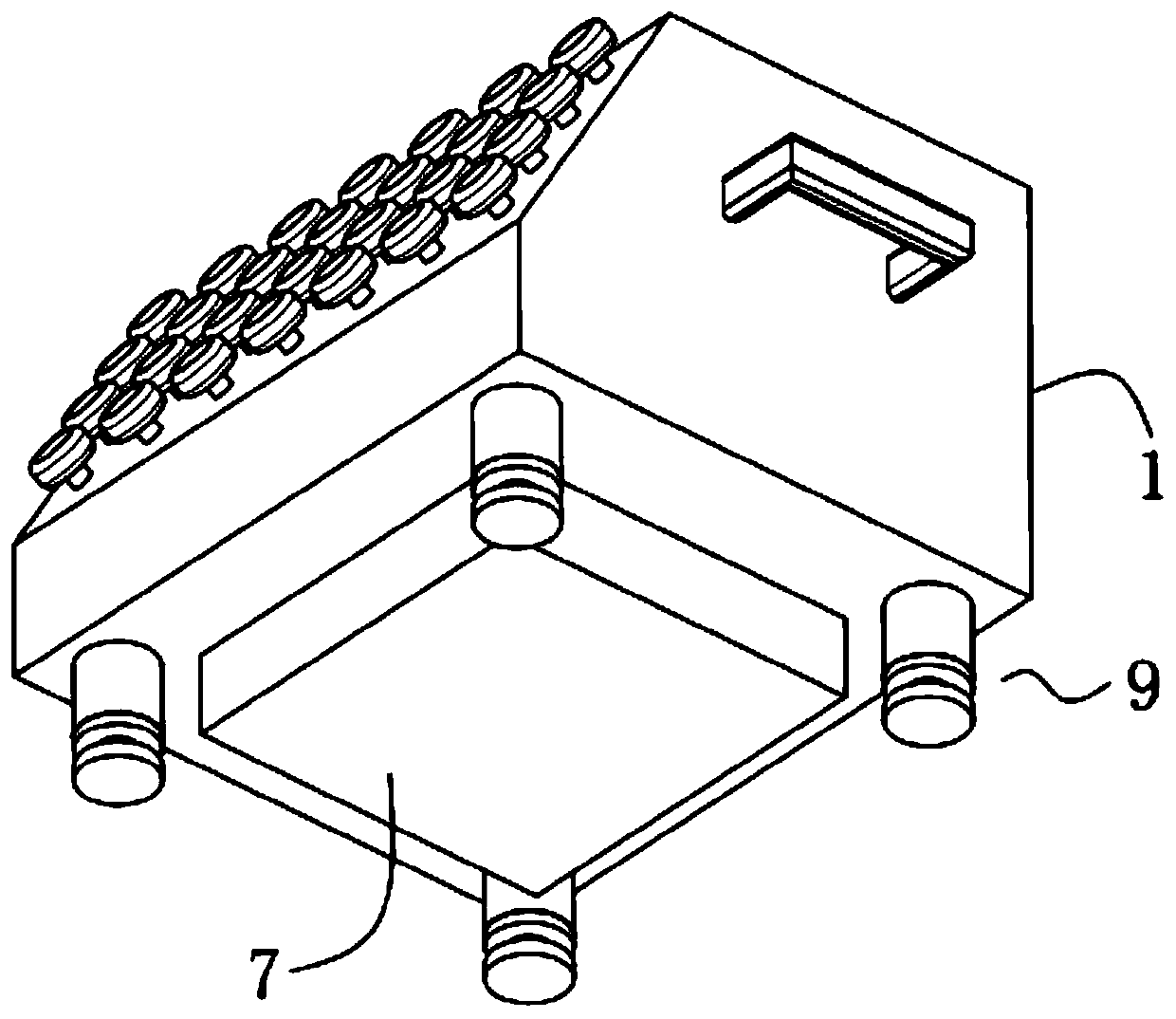

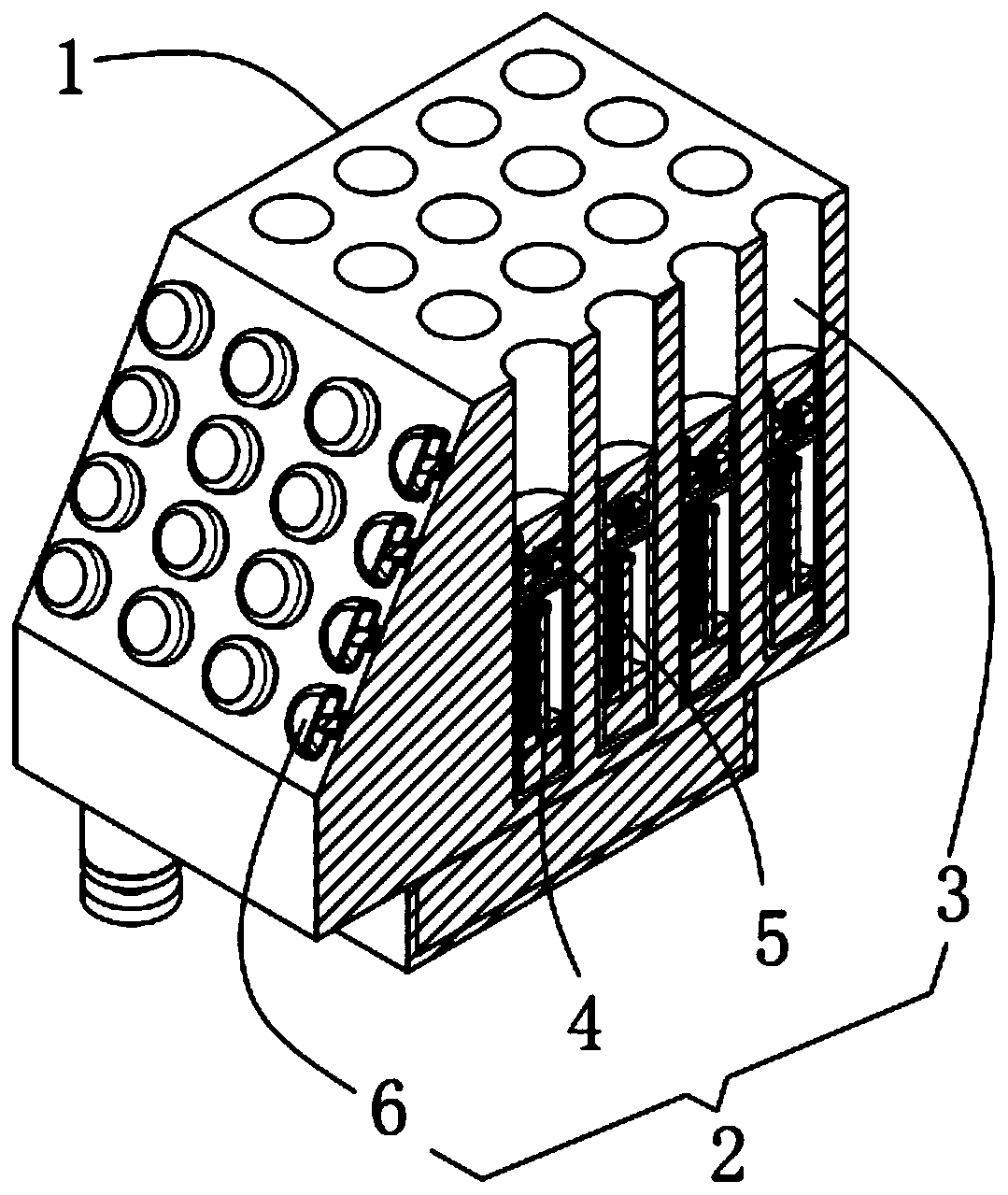

[0051] An insulin pen placement device, such as figure 1 and 3 As shown, it includes a base 1 and several sets of insulin pen placement units 2, the base 1 is a square base, and a slope 10 is opened on the base 1, and several sets of insulin pen placement units 2 are evenly arranged on the on the base 1;

[0052] Such as figure 1 and 3 As shown, each set of insulin pen placement units 2 includes a placement hole 3, an ejection mechanism 4, and a control button 6. The placement hole 3 is opened on the upper surface of the base 1, and the placement hole 3 is vertically The ejection mechanism 4 is fixedly installed on the inner bottom of the placement hole 3 , and the control button 6 is fixedly installed on the slope 10 .

[0053] By adopting the above technical scheme, each group of insulin pen placement units 2 is used to place an insulin pen; the control button 6 is used to control the action of the ejection mechanism 4, and the ejection mechanism 4 is used to eject the i...

Embodiment 2

[0075] The difference from Example 1 is that the surface of the base 1 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0076] Take the following raw materials and weigh them by weight: 16 parts of epoxy resin, 6 parts of calcium carbonate powder, 8 parts of copper oxide powder, 8 parts of nano-silver powder, 9 parts of titanium dioxide powder, 11 parts of acrylic emulsion, 2 parts of paraffin wax, alcohol ester twelve parts 3 parts, BDMA 2 parts, high carbon alcohol fatty acid ester complex 1 part and ethanol 25 parts;

[0077] S1. Add the weighed acrylic emulsion, paraffin, alcohol ester twelve, BDMA, higher alcohol fatty acid ester complex and ethanol into the mixer and stir for 18min at a stirring speed of 500r / min to prepare a mixed solution;

[0078] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, nano-silver powder, and titanium dioxide powder into a pulverizer for pulverization until the pa...

Embodiment 3

[0084] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0085] Take the following raw materials and weigh them by weight: 19 parts of epoxy resin, 8 parts of calcium carbonate powder, 9 parts of copper oxide powder, 9 parts of nano-silver powder, 10 parts of titanium dioxide powder, 12 parts of acrylic emulsion, 3 parts of paraffin wax, alcohol ester twelve parts 4 parts, BDMA 3 parts, high carbon alcohol fatty acid ester complex 2 parts and ethanol 30 parts;

[0086] S1. Add the weighed acrylic emulsion, paraffin, alcohol ester twelve, BDMA, higher alcohol fatty acid ester complex and ethanol into the mixer and stir for 22min at a stirring speed of 550r / min to prepare a mixed solution;

[0087] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, nano-silver powder, and titanium dioxide powder into a pulverizer for pulverization until the particle diameter of the material is not gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com