Material for plastic track and preparation method thereof

A plastic track and powder technology, which is applied in the field of plastic track materials and its preparation, can solve the problems of plastic track tensile strength, plastic track service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

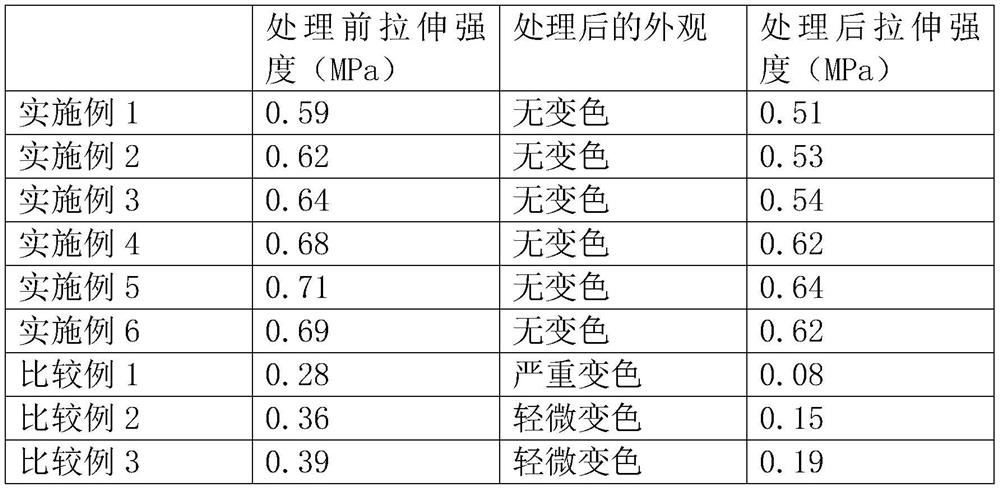

Examples

Embodiment 1

[0074] A material for a plastic runway, including component A and component B;

[0075] Component A includes the following components in parts by mass:

[0076] Polyether polyol 450kg; Environmentally friendly plasticizer 175kg; Tributyl citrate 10kg; Polyurethane curing agent 370kg;

[0077] Component B includes the following components in parts by mass:

[0078] Polyether polyol 485kg; Environmentally friendly plasticizer 210kg; Tributyl citrate 320kg; Dispersant 1kg; Chain extender 100kg; Iron oxide red 35kg; Pigment 4kg; Pottery clay 160kg; Powder 820kg; ; Methyl o-hydroxybenzoate 35kg; Cellulose triacetate 5kg; Fatty alcohol polyoxyethylene ether 1.5kg.

[0079] In this embodiment, the particle size of clay is 350 mesh.

[0080] In this embodiment, the particle size of titanium dioxide is 400 mesh.

[0081] The preparation method of the material for the plastic runway is as follows:

[0082] S1. Preparation of component A: first add 450kg of polyether polyol, 175kg o...

Embodiment 2

[0086] A material for a plastic runway, including component A and component B;

[0087] Component A includes the following components in parts by mass:

[0088] Polyether polyol 440kg; Environmentally friendly plasticizer 165kg; Tributyl citrate 30kg; Polyurethane curing agent 373kg;

[0089] Component B includes the following components in parts by mass:

[0090] Polyether polyol 478kg; Environmental plasticizer 200kg; Tributyl citrate 340kg; Dispersant 0.5kg; Chain extender 105kg; Iron oxide red 38kg; Pigment 3kg; Pottery clay 180kg; ; Methyl o-hydroxybenzoate 30kg; Cellulose triacetate 3kg; Fatty alcohol polyoxyethylene ether 1kg.

[0091] In this embodiment, the particle size of clay is 380 mesh.

[0092] In this embodiment, the particle size of titanium dioxide is 450 mesh.

[0093] The preparation method of the material for the plastic runway is as follows:

[0094] S1. Preparation of component A: first add 440kg of polyether polyol, 165kg of environmentally friendl...

Embodiment 3

[0098] A material for a plastic runway, including component A and component B;

[0099] Component A includes the following components in parts by mass:

[0100] Polyether polyol 430kg; Environmentally friendly plasticizer 170kg; Tributyl citrate 20kg; Polyurethane curing agent 375kg;

[0101] Component B includes the following components in parts by mass:

[0102] Polyether polyol 470kg; Environmental plasticizer 205kg; Tributyl citrate 330kg; Dispersant 0.8kg; Chain extender 103kg; Iron oxide red 40kg; Pigment 3.5kg; 0.5kg; methyl o-hydroxybenzoate 40kg; cellulose triacetate 4kg; fatty alcohol polyoxyethylene ether 2kg.

[0103] In this embodiment, the particle size of clay is 400 mesh.

[0104] In this embodiment, the particle size of titanium dioxide is 500 mesh.

[0105] The preparation method of the material for the plastic runway is as follows:

[0106] S1. Preparation of component A: first add 430kg of polyether polyol, 170kg of environmentally friendly plasticizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com