Preparation method of high-concentration microalgae living cell long-acting preservative

A technology of living cells and preservatives, applied in the field of cell viability maintenance and improvement, can solve the problems of high cost, corruption, loss of nutrients in algal cells, etc., and achieve the effect of maintaining vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

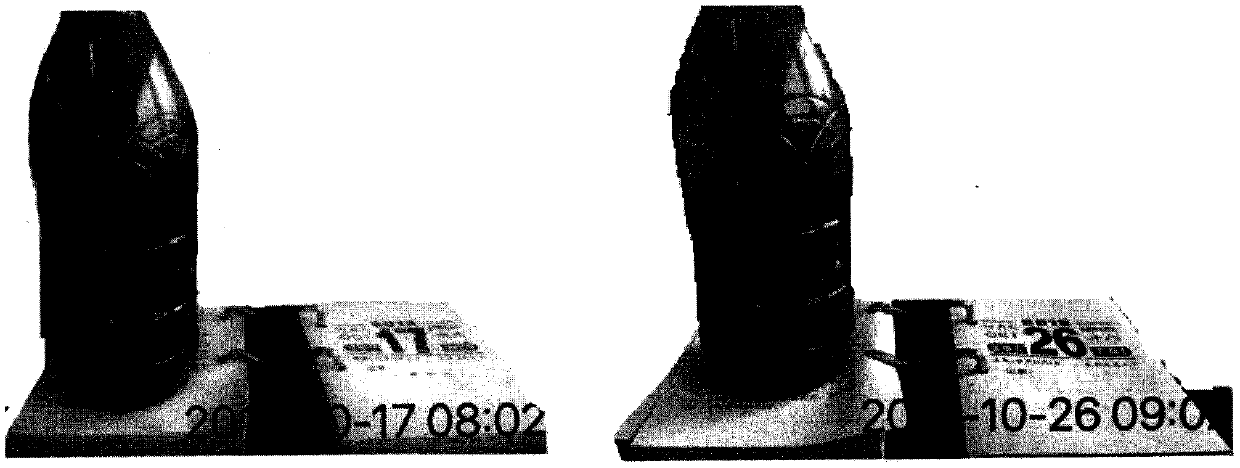

Image

Examples

Embodiment 1

[0035] Step 1. Make the cell concentration 2×10 6 / ml of Rhodopseudomonas capsulate and Halomonas campisalis were respectively inoculated into glutamate medium, cultured at 30°C in a 30L fermenter, the volume of culture solution was 15L, and aeration cultured 48h, Rhodopseudomonas capsulatum was 3×10 10 cfu / ml, the density of Halomonas campisalis is 2.8×10 10 cfu / ml, take 10L of each sample, and mix to obtain 20L mixed bacterial liquid. Centrifuge at 5000g for 10 minutes to obtain about 100mL of bacterial slurry.

[0036] Step 2: Mix 100ml of sodium alginate solution with a concentration of 20g / L and 100ml of bacterial mud collected in step 1, stir evenly, then add 10g / L of calcium chloride solution, and stir at the same time, after adding about 400ml, the solution When the degree of turbidity no longer deepens, let it stand for 30 minutes, then pour it into a bag made of 1500-mesh filter cloth, and let it stand for 1 hour. The liquid in the bag no longer seeps out, and abo...

Embodiment 2

[0046] Steps 1 to 4 are the same as Example 1,

[0047] Step 5. Store the mixed algal solution at 15-30°C in the dark.

[0048] At 2 days, 8 days, 1 month, and 2 months after storage, the odor was observed, and the viability was determined by PI-FDA staining.

[0049] Table 2. Test results of freshwater chlorella at different storage times

[0050] Sampling time odor survival rate 0 days Algae natural earthy smell 98% 2 days later Algae natural earthy smell 96% 8 days later Algae natural earthy smell 95% 1 month later Slightly odorous earthy algae 92% 2 months later putrid smell 12%

[0051] During the preservation process of freshwater Chlorella, its cell viability decreased gradually with the prolongation of preservation time. After being stored for one month, the survival rate is still 92%; within two months, it has been putrefied and only about 12% of the algal cells are alive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com