PtAu nano catalyst with controllable active site spacing and preparation method thereof

A nano-catalyst and active site technology, applied in the direction of electrochemical generators, fuel cells, structural parts, etc., can solve the problem that the catalyst cannot meet the requirements of anode catalysis, and achieve the goal of improving electrocatalytic performance, high stability and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

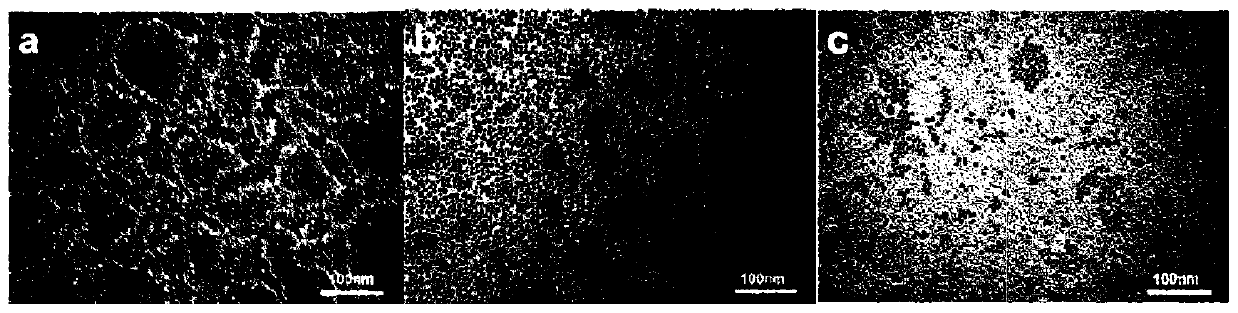

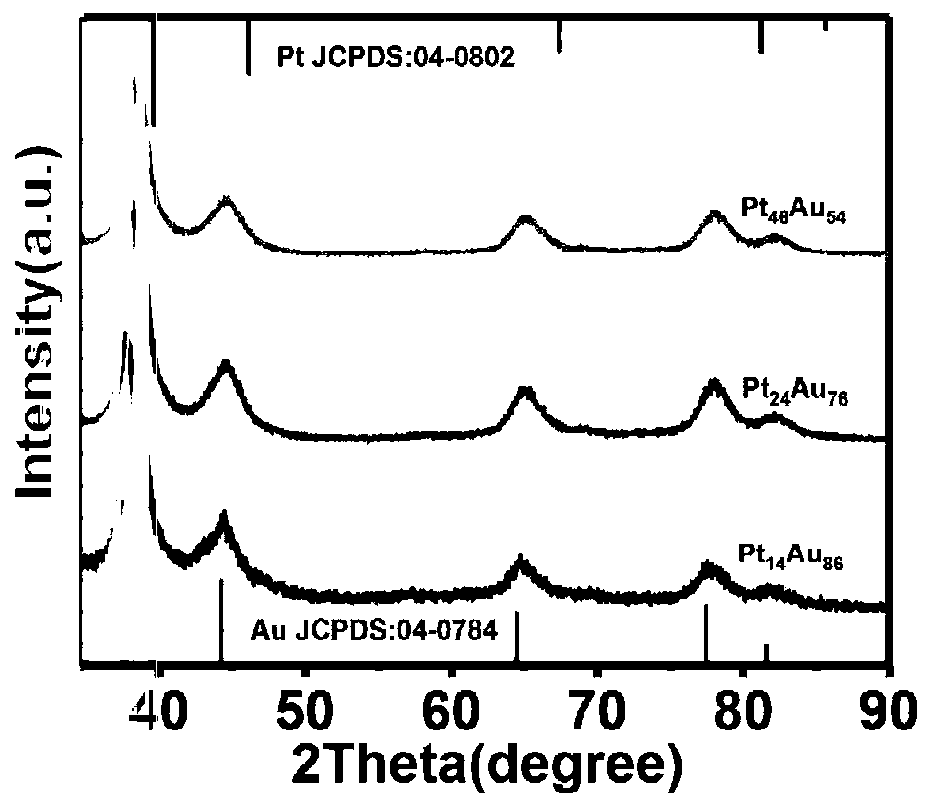

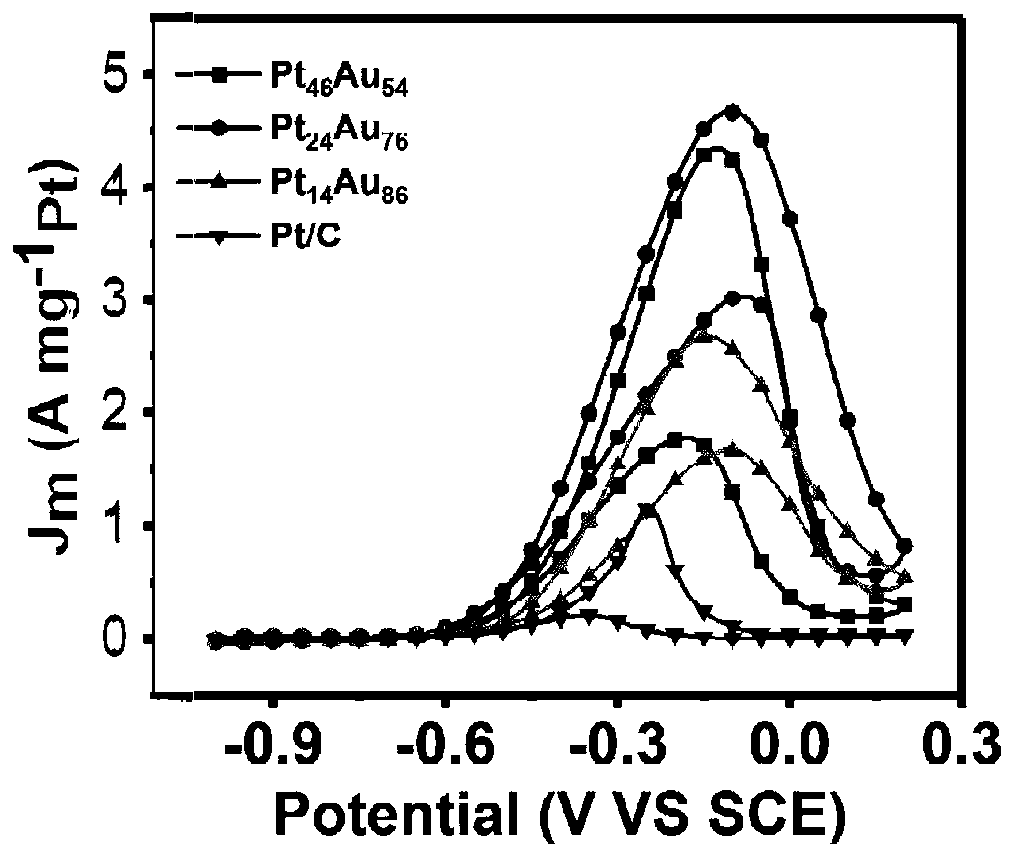

Embodiment 1

[0019] a. Add 19.7mg platinum acetylacetonate, 20.6mg chloroauric acid, 200mg three

[0020] N-octyl phosphine oxide, 4mL oleylamine and 6mL octadecene, blow nitrogen, and stir the solution until it becomes transparent.

[0021] b. Rapidly raise the temperature of the solution to 260°C, keep the temperature constant for 60 minutes, and then cool it naturally to 80°C.

[0022] c. Mix the reaction solution with cyclohexane and ethanol and centrifuge to wash, and the resulting precipitate has a controllable active site spacing

[0023] PtAu nanocatalysts, denoted as Pt 46 Au 54 alloy.

Embodiment 2

[0025] a. Add 9.8 mg of platinum acetylacetonate, 30.9 mg of chloroauric acid, 200 mg of tri-n-octyl phosphine oxide, 4 mL of oleylamine and 6 mL of octadecene into a 50 mL three-neck flask, blow nitrogen gas, and stir the solution until it becomes transparent.

[0026] b. Rapidly raise the temperature of the solution to 260°C, keep the temperature constant for 60 minutes, and then cool it naturally to 80°C.

[0027] c. The reaction liquid is mixed with cyclohexane and ethanol and centrifuged to wash, and the resulting precipitate is a PtAu nanocatalyst with a controllable active site spacing, denoted as Pt 24 Au 76 Alloy, surface Pt / Au atomic ratio 1:1.

Embodiment 3

[0029] a. Add 6.7mg of platinum acetylacetonate, 32.7mg of chloroauric acid, 500mg of tri-n-octylphosphine oxide, 4mL of oleylamine and 6mL of octadecene into a 50mL three-necked flask, blow nitrogen gas, and stir the solution to a transparent state.

[0030] b. Rapidly raise the temperature of the solution to 260°C, keep the temperature constant for 60 minutes, and then cool it naturally to 80°C.

[0031] c. The reaction liquid is mixed with cyclohexane and ethanol and centrifuged to wash, and the resulting precipitate is a PtAu nanocatalyst with a controllable active site spacing, denoted as Pt 14 Au 86 alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com