Treatment process for improving dimensional stability of Chinese fir logs

A technology of dimensional stability and processing technology, applied in the direction of wood treatment, wood heat treatment, wood treatment details, etc., can solve the problem of limited improvement of fir stability, and achieve improved fir stability, reduced porosity, and improved dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

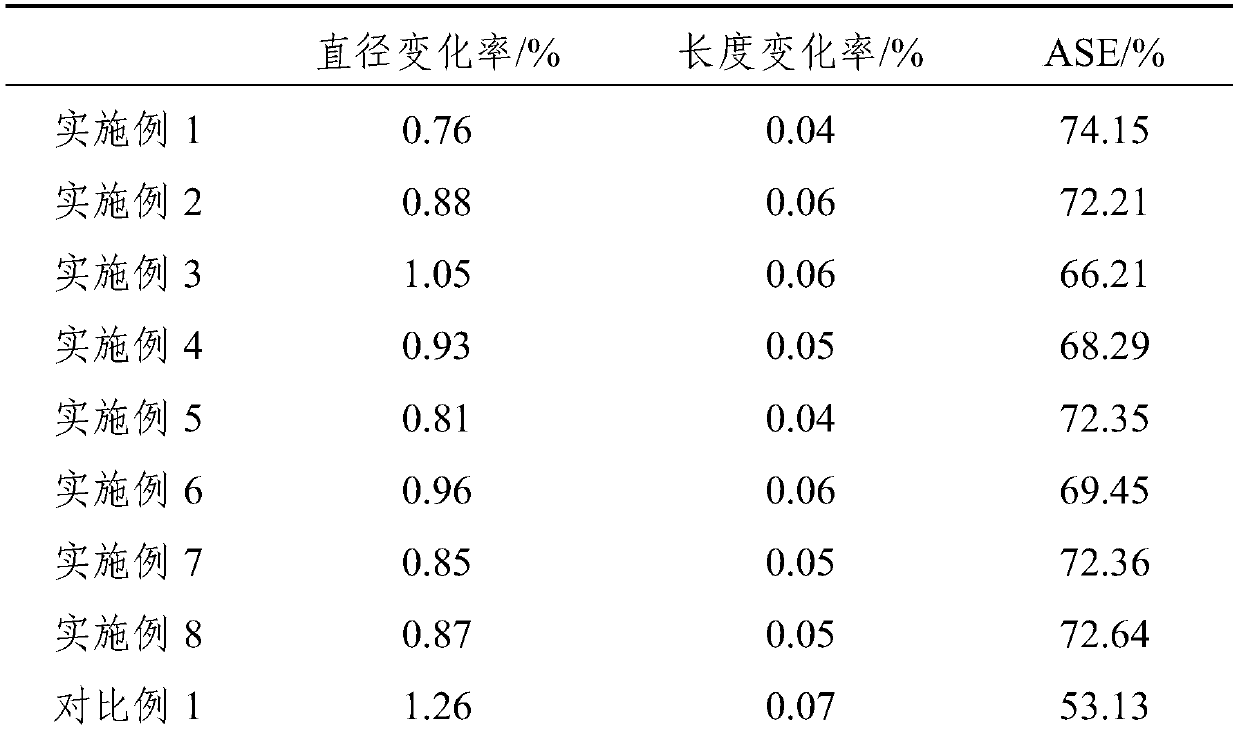

Embodiment 1

[0040] A treatment process for improving the dimensional stability of fir logs, comprising the following steps:

[0041] (1) the moisture content of the Chinese fir log with a diameter of 170-180mm is controlled between 40-55%; then the Chinese fir log is placed in a drying room, and the ambient temperature is adjusted to 65-70°C, and the ambient humidity is 45-60%. In this environment, let the fir logs stand for 15h; then cool down to room temperature.

[0042] (2) Chinese fir logs are placed in a sodium carbonate solution with a mass concentration of 2.7%, and an appropriate amount of sucrose is added so that the mass concentration of sucrose in the sodium carbonate solution is 4.5%, pressurized at room temperature, and the pressurized pressure is 0.55MPa , the pressurization time is 100min, and then the pressure is released, and the fir logs are taken out.

[0043] (3) After soaking fir logs in glycerin at room temperature for 3 hours, slowly raise the temperature of glyce...

Embodiment 2

[0046] A treatment process for improving the dimensional stability of fir logs, comprising the following steps:

[0047] (1) the moisture content of the Chinese fir log with a diameter of 100-110mm is controlled between 40-55%; then the Chinese fir log is placed in a drying room, and the ambient temperature is adjusted to 65-70°C, and the ambient humidity is 45-60%. In this environment, let the fir logs stand for 16h; then cool down to room temperature.

[0048] (2) Chinese fir log is placed in the sodium carbonate solution that mass concentration is 2.7%, and adds appropriate amount of sucrose, makes the mass concentration of sucrose in sodium carbonate solution 4.5%, pressurizes at normal temperature, and pressurization pressure is 0.6MPa, The pressurization time is 60 minutes, and then the pressure is released, and the fir logs are taken out.

[0049](3) After soaking fir logs in glycerin at room temperature for 1.5 hours, slowly raise the temperature of glycerin to 110°C ...

Embodiment 3

[0052] A treatment process for improving the dimensional stability of fir logs, comprising the following steps:

[0053] (1) the moisture content of the Chinese fir log with a diameter of 60-70mm is controlled between 40-55%; then the Chinese fir log is placed in a drying room, the ambient temperature is adjusted to 65-70°C, and the ambient humidity is 45-60%, In this environment, let the fir logs stand for 12h; then cool down to room temperature.

[0054] (2) Chinese fir logs are placed in a sodium carbonate solution with a mass concentration of 3.2%, and an appropriate amount of sucrose is added, so that the mass concentration of sucrose in the sodium carbonate solution is 5.5%, pressurized at room temperature, and the pressurized pressure is 0.6MPa , the pressurization time is 60min, and then the pressure is released, and the fir logs are taken out.

[0055] (3) After soaking fir logs in glycerin at room temperature for 1 hour, slowly raise the temperature of glycerin to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com