Single-core cable for new energy single-rail railway system

A single-track railway, single-core cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., to achieve the effect of small fire area, easy space layout, and lightweight cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

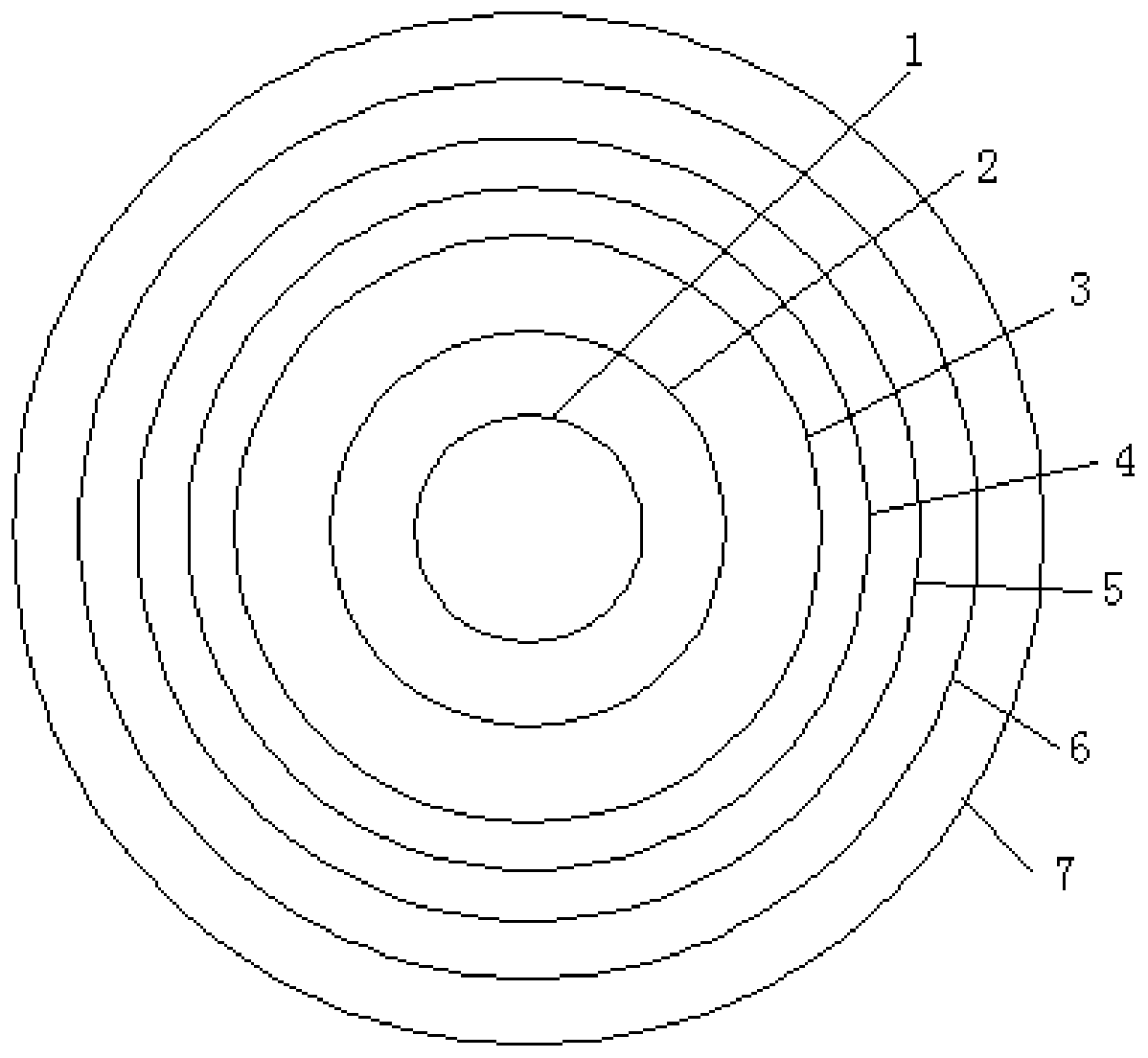

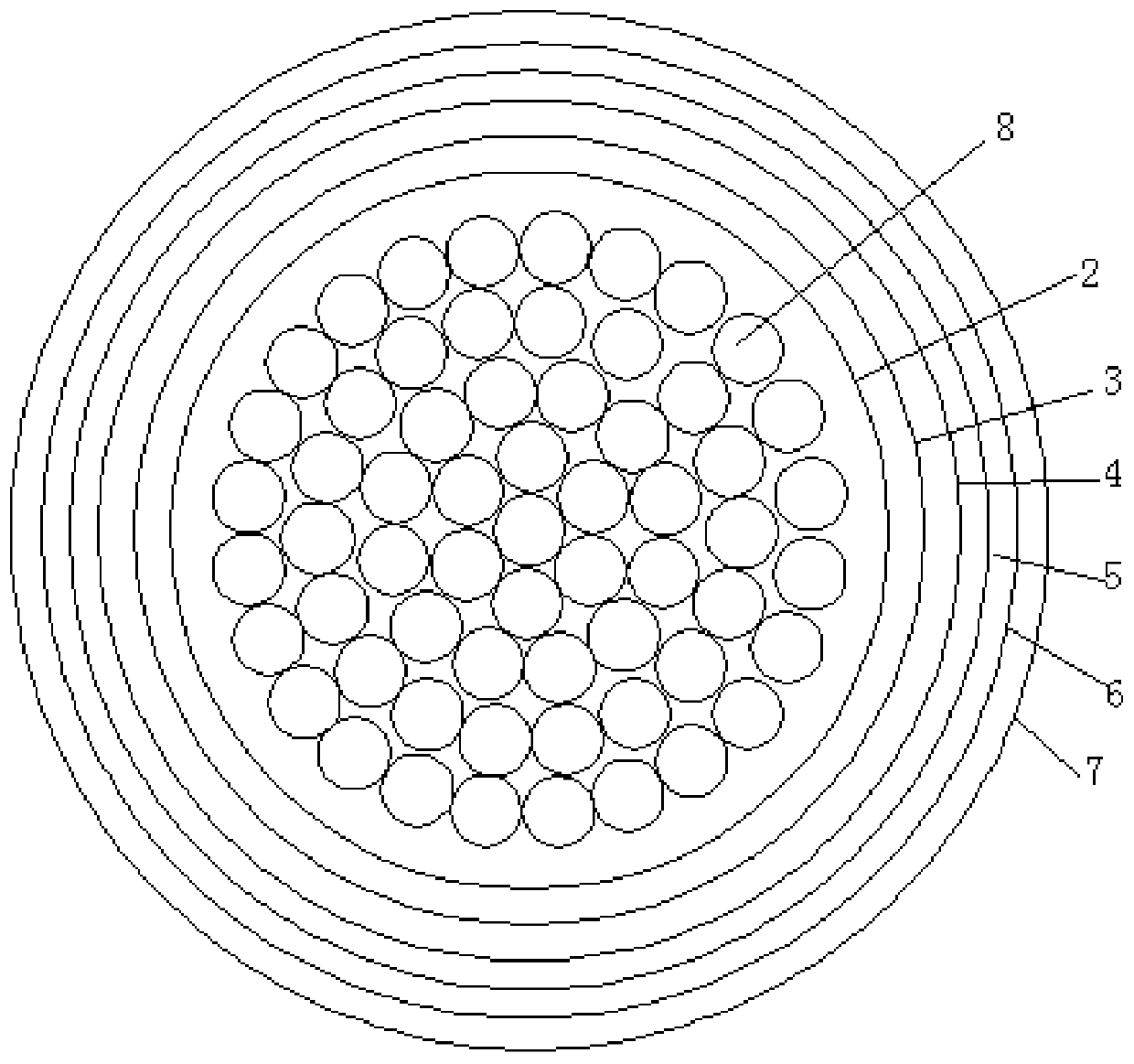

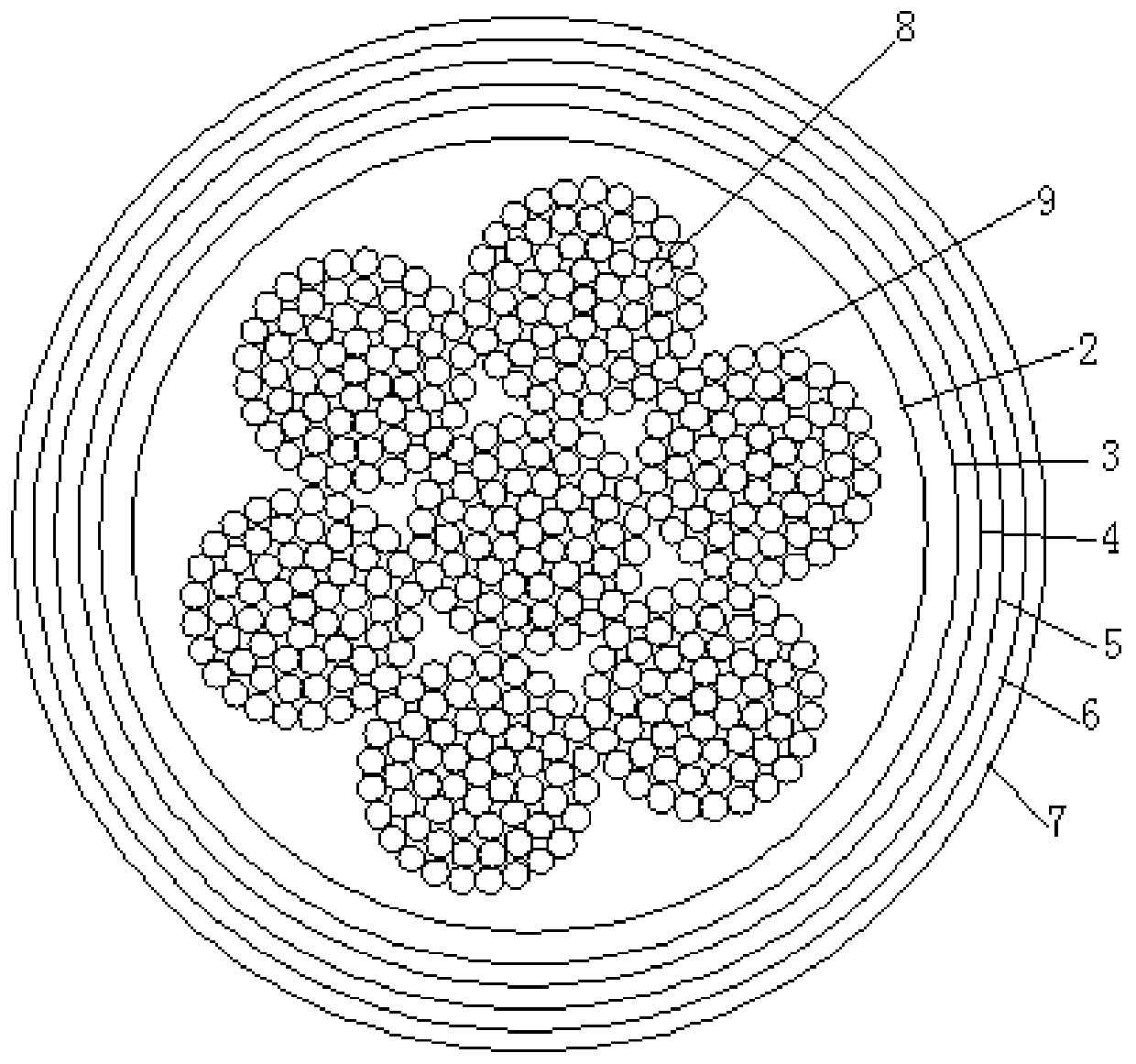

[0019] Such as figure 1 , 2 As shown in , 3, a single-core cable for a new energy monorail railway system includes a conductor 1, and the outer side of the conductor 1 is coated with a halogen-free low-smoke flame-retardant irradiation cross-linked polyolefin insulating layer 2 and a glass fiber tape Add ceramic silicone rubber belt fireproof layer 3, tinned copper wire braided shielding layer 4, nano silicon waterproof glue filling layer 5, aluminum alloy belt interlocking armor layer 6 and halogen-free low-smoke flame-retardant radiation cross-linked polyolefin protective layer Sheath layer 7; the specification of the conductor 1 is 16mm 2 The conductors below are made of tinned annealed copper wire 8, which are stranded into conductors by layering and small pitches. The central layer is a tinned copper wire, and the number of twisted layers is 4 layers, each layer is 6, 12 strands, 18 strands, 24 strands, the stranding direction of the outermost layer is leftward, the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com