Combined osmotic and hydrogel cervical dilators and method of making same

A dilator and hydrogel technology, applied in the field of cervical dilators, can solve the problems of irregular dry stem shape and geometry, low mechanical strength, slow hydration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

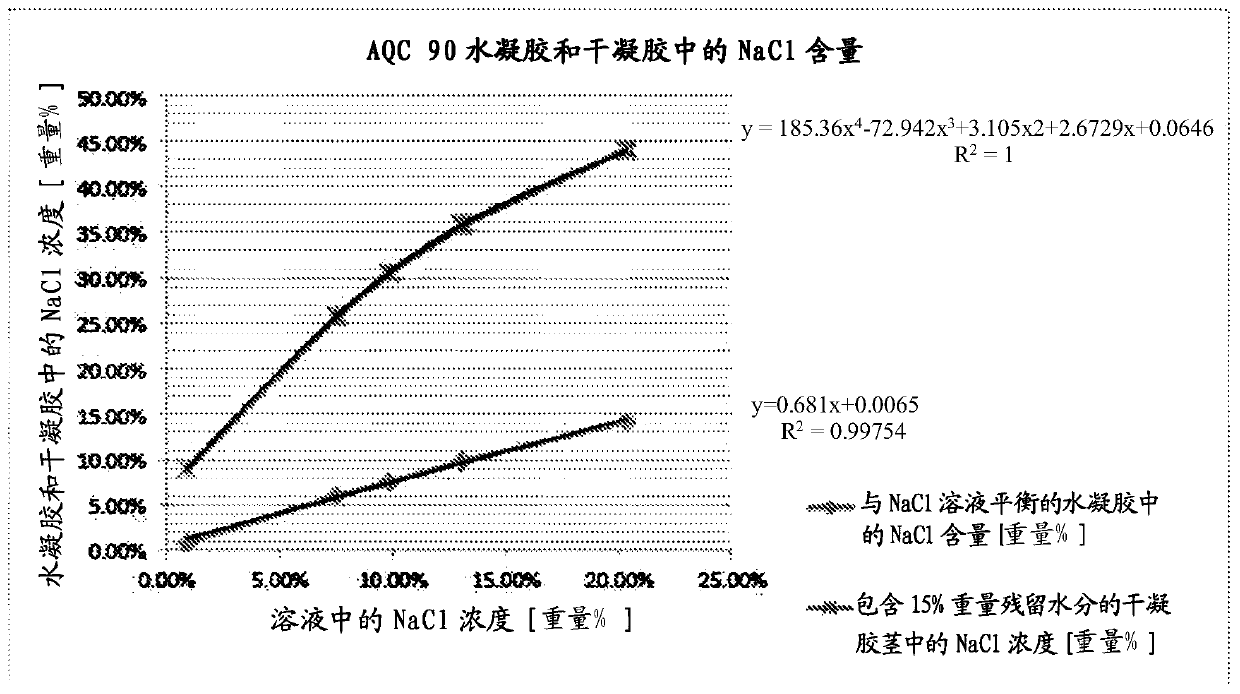

[0055] Hydrogels for cervical dilators were prepared according to US Patent 6,232,406, which is incorporated by reference in its entirety. PAN having a weight average molecular weight of 200,000 g / mol was dissolved in a 55% by weight NaSCN aqueous solution to form a 10% by weight polymer solution. NaOH dissolved in 55% by weight aqueous NaSCN solution was added at ambient temperature in the amount required to obtain a PAN / NaOH mass ratio of 1:10. The solution was then transferred to a jacketed tubular reactor where it was heated to 70°C for 60 hours. The resulting multi-block acrylic copolymer solution was cooled to 40°C and transferred to a pressure vessel, which was then fed by pressurized gas into a metering pump with a progressing cavity rotor. The solution is extruded through a cooling nozzle into a coagulation bath filled with an aqueous NaSCN solution having a NaSCN concentration of 1 to 5% by weight. The coagulated hydrogel sticks were washed until substantially all ...

Embodiment 2

[0061] The hydrogel prepared according to Example 1 was soaked with an aqueous solution of 10% by weight of the following monomers:

[0063] 2. Methacryloxypropane-1-sulfonic acid

[0064] 3.4-Vinylphenylsulfuric acid

[0065] 4. Vinylphosphonic acid.

[0066] After each solution reached equilibrium, the monomer-soaked hydrogel sticks were stretched on a drying rack similarly to Example 1, and dried at 80 °C for 18 h. Although no initiator was used and drying was performed in the presence of air, all monomers polymerized and formed an interpenetrating network of polyelectrolytes within the multi-block copolymer hydrogel. When swollen in isotonic solution, no elution of the polyelectrolyte was observed because it was apparently firmly anchored within the hydrogel structure.

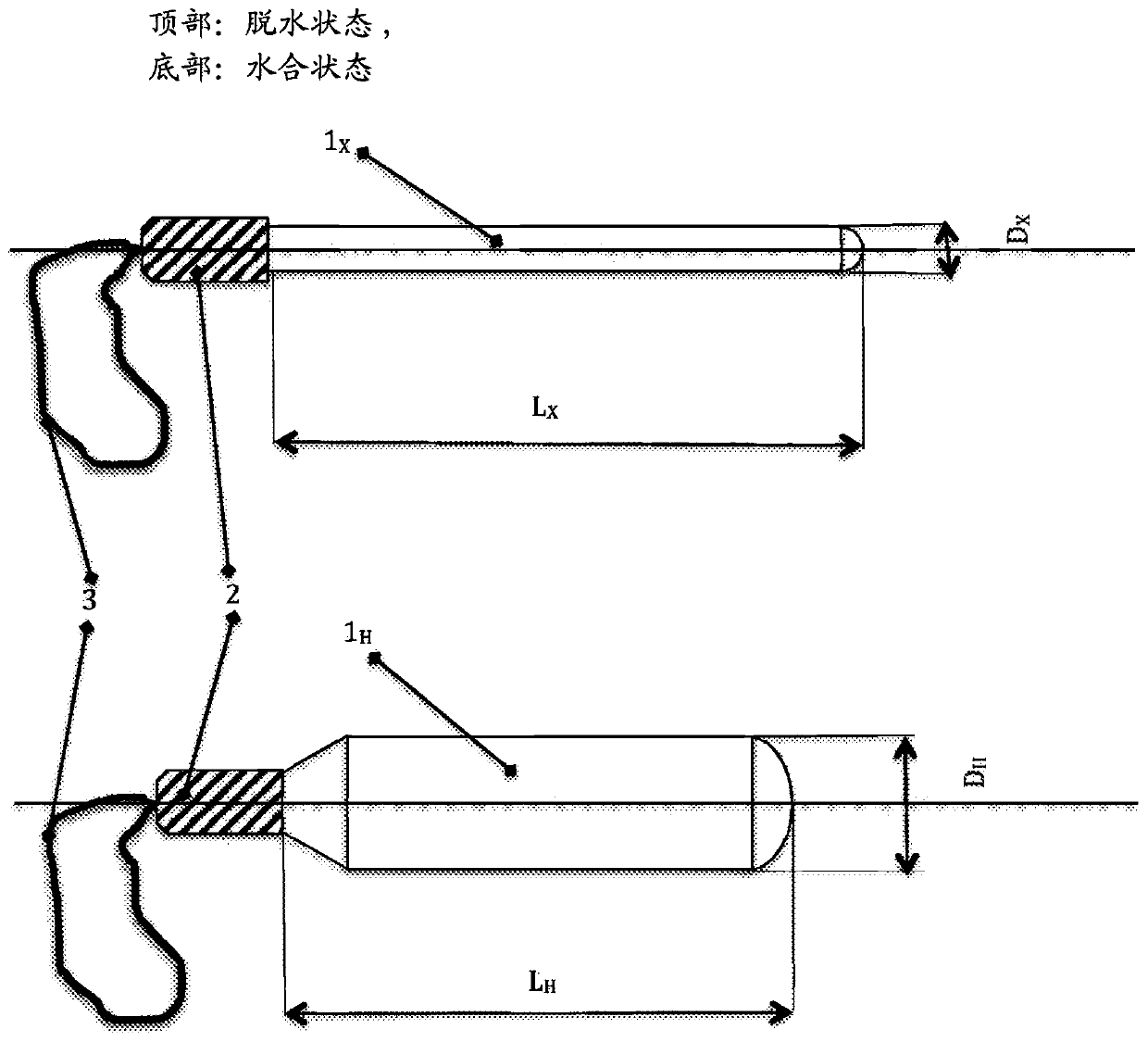

[0067] The xerogel stem can then be equipped with a glued plastic handle and sterilized by radiation or gas. figure 2 A cervical dilator is shown in a dehydrated state (up...

Embodiment 3

[0070] The hydrogel interpenetrating network of Example 2 with poly(methacryloxypropane-1-sulfonic acid) monomer was treated with an excess of 5% by weight sodium sulfate, 3% by weight 1,2-propylene glycol and 1 Soak in an aqueous solution of wt% triethanolamine. Then, it was dried under radial tension at 70° C. until a residual water content of about 18% by weight was reached. The product is then cut to size, trimmed, fitted with a handle and sealed in a sterilization bag, as in the previous embodiment. The cervical dilator device was sterilized by electron beam at 40 kGy. This cervical dilator device provides rapid cervical ripening, has strong radial dilation and can be shaped to fit any specific endocervical canal geometry prior to insertion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com