Titanium dioxide/graphene/metal elemental ternary composite photocatalytic material and photoreduction preparation method thereof

A photocatalytic material, titanium dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of inability to fully utilize the high-efficiency performance of graphene and low cost performance , can not adapt to other problems, to achieve the effect of high-efficiency photolysis of water to produce hydrogen, simple synthesis method, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

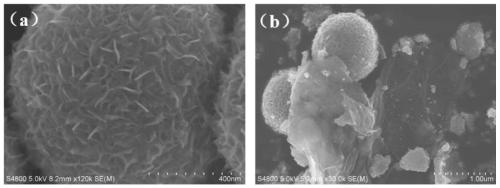

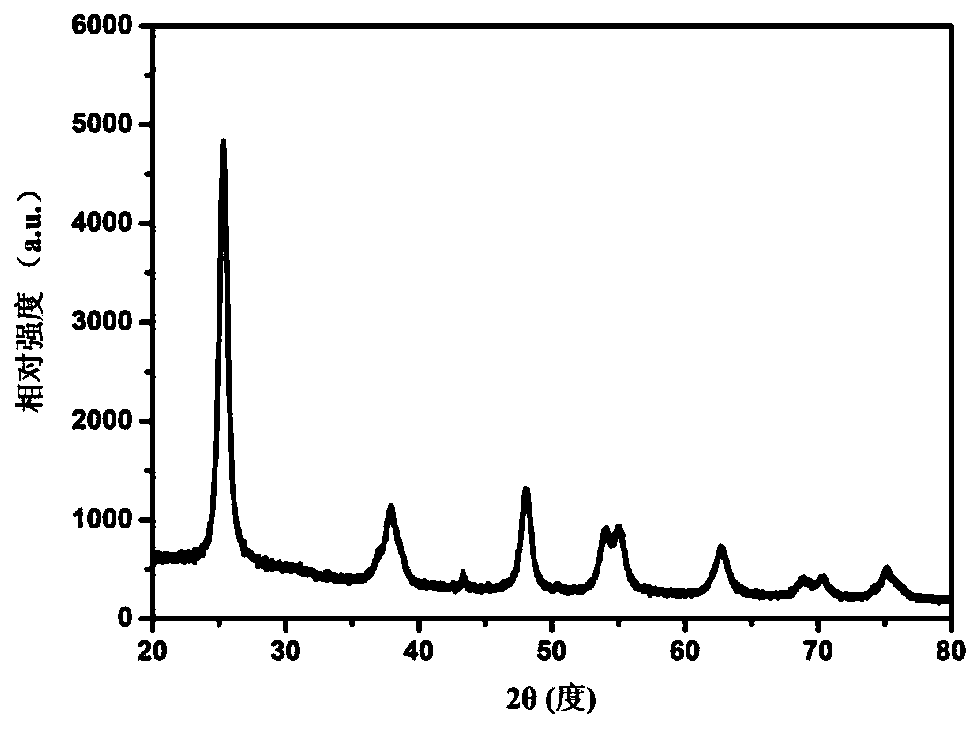

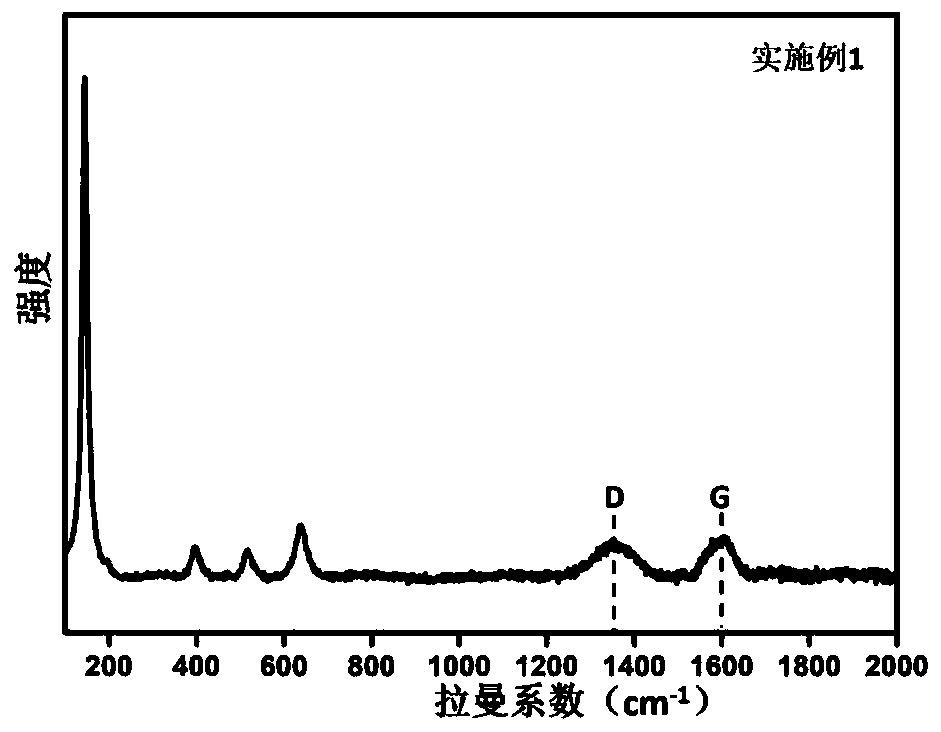

[0042] (1) Using isopropanol as a solvent, diethylenetriamine as a template, and isopropyl titanate as a titanium source, sintering at 200°C and 400°C to form flower-shaped porous titanium oxide;

[0043] (2) Take 4mL 2mg / mL graphene oxide in 100mL absolute ethanol and ultrasonically disperse for 30 minutes;

[0044] (3) Add 0.4 g of titanium dioxide obtained in (1) to the solution obtained in (2), and ultrasonically disperse for 10 minutes;

[0045] (4) Place the solution obtained in (3) under light at a wavelength of 365nm for 9h, and continue to stir at a constant speed;

[0046] (5) Add 1.25mL 0.05mol / L copper chloride precursor solution to the solution obtained in (4), continue to irradiate with light with a wavelength of 365nm for 3h, and stir at a constant speed;

[0047](6) Filter the product obtained in (5) to take the filter residue, wash with absolute ethanol and centrifuge, repeat the cleaning and centrifugation process at least three times, and then dry at 60°C t...

Embodiment 2

[0051] (1) Using isopropanol as a solvent, diethylenetriamine as a template, and isopropyl titanate as a titanium source, sintering at 200°C and 400°C to form flower-like porous titanium oxide;

[0052] (2) Take 4mL 2mg / mL graphene oxide in 100mL absolute ethanol and ultrasonically disperse for 30 minutes;

[0053] (3) Add 0.4 g of titanium dioxide obtained in (1) to the solution obtained in (2), and ultrasonically disperse for 10 minutes;

[0054] (4) Place the solution obtained in (3) under light at a wavelength of 365nm for 9h, and continue to stir at a constant speed;

[0055] (5) Add 740 μL of 0.05mol / L silver nitrate precursor solution to the solution obtained in (4), continue to irradiate with light with a wavelength of 365nm for 3h, and stir at a constant speed;

[0056] (6) Filter the product obtained in (5) to take the filter residue, wash with absolute ethanol and centrifuge, repeat the cleaning and centrifugation process at least three times, and then dry at 60°C ...

Embodiment 3

[0060] (1) Using isopropanol as a solvent, diethylenetriamine as a template, and isopropyl titanate as a titanium source, sintering at 200°C and 400°C to form flower-shaped porous titanium oxide;

[0061] (2) Take 4mL 2mg / mL graphene oxide in 100mL absolute ethanol and ultrasonically disperse for 30 minutes;

[0062] (3) Add 0.4 g of titanium dioxide obtained in (1) to the solution obtained in (2), and ultrasonically disperse for 10 minutes;

[0063] (4) Place the solution obtained in (3) under light at a wavelength of 365nm for 9h, and continue to stir at a constant speed;

[0064] (5) Add 400 μL 0.05mol / L chloroauric acid precursor solution to the solution obtained in (4), continue to irradiate with light with a wavelength of 365nm for 3h, and stir at a constant speed;

[0065] (6) Filter the product obtained in (5) to take the filter residue, wash with absolute ethanol and centrifuge, repeat the cleaning and centrifugation process at least three times, and then dry at 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com