Method for increasing production of methane through corn straw anaerobic dry fermentation bacteria agent and biogas liquid reflux

A technology for corn stalks and fermentation inoculants is applied in the field of corn stalk anaerobic dry fermentation inoculants and biogas slurry reflux to increase methane production. The effect of liquid production, promotion of fermentation gas production, and stable heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

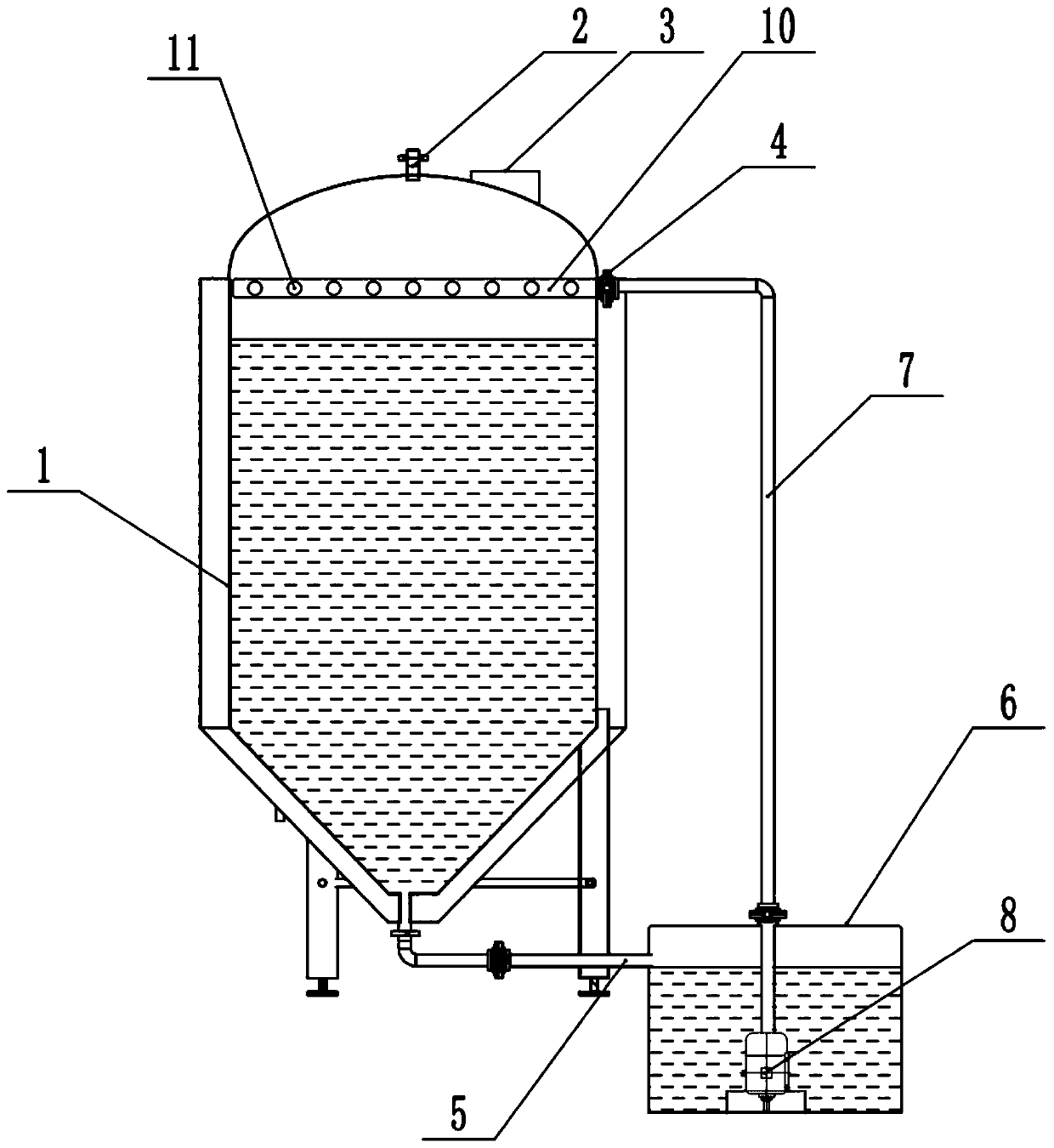

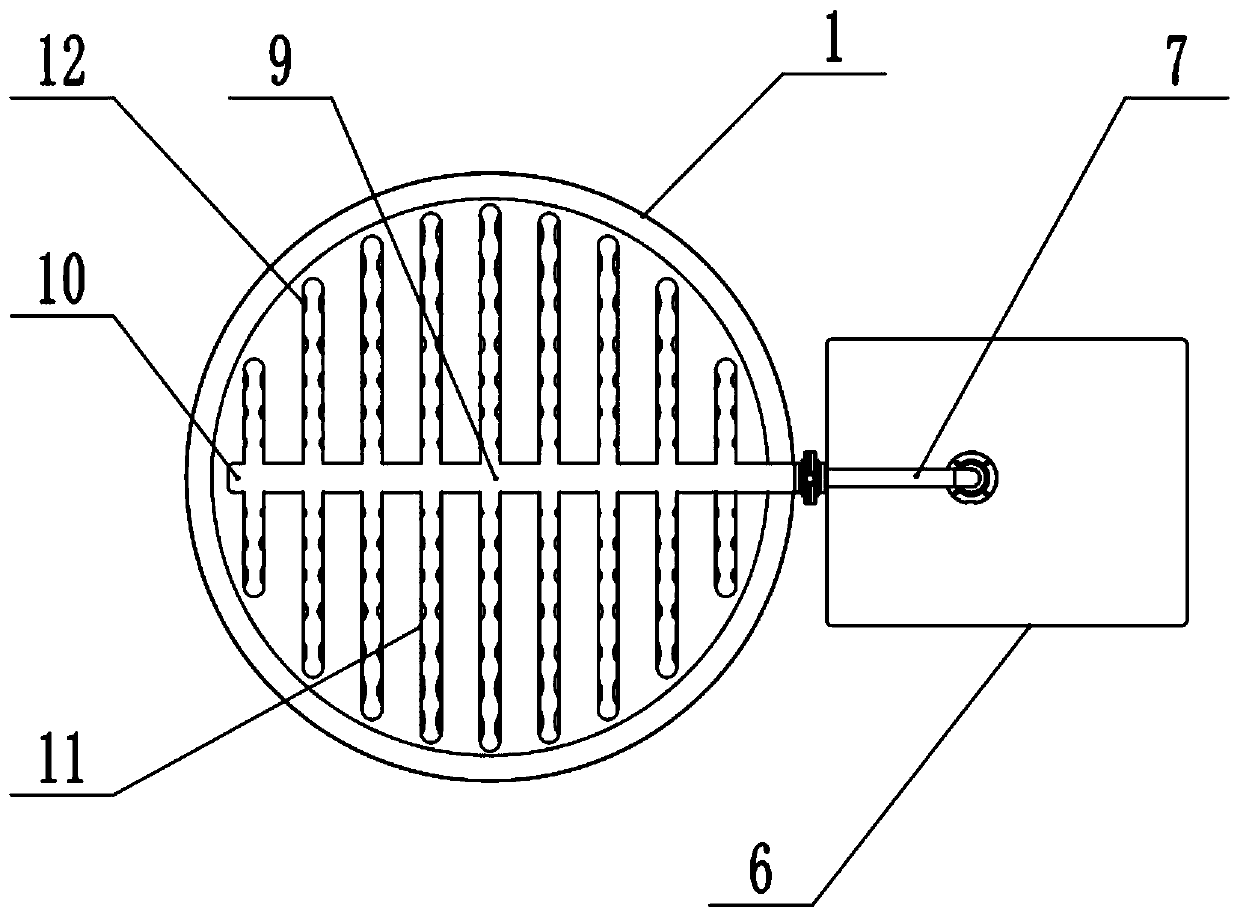

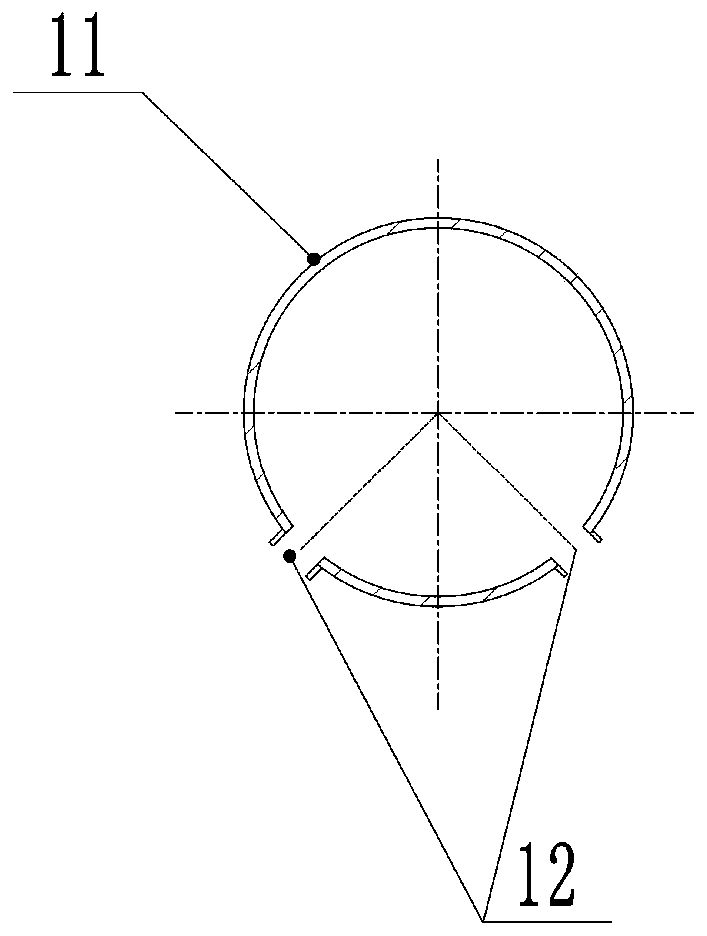

[0044] Such as Figure 1-3 The device for increasing the production of methane by returning biogas slurry from anaerobic dry fermentation of corn stalks includes:

[0045] Anaerobic dry fermentation tank 1, with a volume of 300m 3 The airtight tank body is provided with a feed hole 3 and a liquid inlet hole 4 on the tank body, an air outlet hole 2 is provided on the top of the tank body, the bottom of the tank body is inclined at 3-5°, and the bottom end of the anaerobic dry fermentation tank 1 is provided with a Biogas slurry outlet 5, which is convenient for biogas slurry collection to flow into biogas slurry outlet 5;

[0046] Biogas slurry storage tank 6, with a volume of 3m 3 The airtight liquid storage tank is provided with a storage tank liquid inlet and a storage tank liquid outlet, the storage tank liquid inlet is connected with the biogas slurry outlet 5 of the anaerobic dry fermentation tank 1 through a pipeline 7, and the storage tank liquid outlet is connected t...

Embodiment 2

[0051] A corn stalk anaerobic dry fermentation bacterial agent prepared by the following method:

[0052] (1) Get Bacillus pumilus, through activation, seed culture, expansion culture, the obtained thalline concentration is 10×10 9 The Bacillus pumilus fermentation liquid of cfu / g;

[0053] (2) get bacillus halotolerant, through activation, seed culture, expanded culture, the obtained thalline concentration is 6 * 10 9 The halotolerant bacillus fermentation liquid of cfu / g;

[0054] (3) Get the jelly-like bacillus, through activation, seed culture, expansion culture, the obtained thalline concentration is 6 * 10 9 The jelly-like bacillus fermentation liquid of cfu / g;

[0055] (4) Get Paenibacillus polymyxa, through activation, seed culture, and expanded culture, the obtained thalline concentration is 6×10 9 Paenibacillus polymyxa fermentation broth of cfu / g;

[0056] (5) Get Enterococcus faecalis, through activation, seed culture, expansion culture, the obtained bacterium...

Embodiment 3

[0067] Using the different microbial agents prepared in Example 2 and Comparative Examples 1-2 respectively, combined with the device in Example 1, methane production is carried out according to the following method, and the specific steps are as follows:

[0068] (1) Crushing the corn stalks with a pulverizer to a particle size of 1.5 cm to obtain straw chips;

[0069] (2) adding water to the straw chips obtained in step (1) to adjust the water content to 70%, putting them into an anaerobic dry fermentation tank 1, and performing anaerobic fermentation for 2 months to obtain pre-fermentation raw materials;

[0070] (3) add biogas residues of equal quality to the pre-fermentation raw material of step (2) in the anaerobic dry fermentation tank 1 through the feed hole 3, then add the fermenting bacterial agent of 4% of the pre-fermentation raw material quality, at a temperature of 36 ° C, Under the condition of pH value 8.0, anaerobic dry fermentation is carried out, and the bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com